16.5g black annealed tie wire price factories

Understanding the Pricing of 16.5g Black Annealed Tie Wire from Factories

In the realm of construction and manufacturing, the choice of materials plays a crucial role in the efficiency and durability of projects. One such material frequently used is the black annealed tie wire, known for its versatility and strength. Crafted from high-quality steel, this wire is essential for binding and tying various structural components together. A focal point for industries utilizing this product is the pricing, particularly for the 16.5g black annealed tie wire, which has garnered significant attention.

The term 16.5g refers to the gauge of the wire, indicating its thickness. Both the thickness and tensile strength of the wire contribute to its operational effectiveness. With a gauge of 16.5, the wire strikes a perfect balance; it is sturdy enough to handle heavy weights while remaining flexible enough for easy handling. This unique combination makes it a favored choice among contractors and DIY enthusiasts alike.

When considering the price of 16.5g black annealed tie wire, various factors come into play. Primarily, the manufacturing process and raw material costs significantly influence the final pricing. Factories that produce this type of wire often rely on high-quality steel as their primary raw material. Fluctuations in the global steel market can cause the prices to shift, with supply chain dynamics also playing a pivotal role. Additionally, the annealing process, which involves heating the wire and then cooling it to remove impurities and improve flexibility, adds another layer of complexity and cost to the production.

16.5g black annealed tie wire price factories

Moreover, the location of the factory can affect shipping and operational costs, further impacting pricing structures. Factories situated near steel mills may have a cost advantage compared to those located further away, as transportation expenses can be substantial. Thus, when evaluating prices, it is crucial to consider the geographic positioning of the manufacturing factory.

Another aspect that influences pricing is market demand. In construction and manufacturing, trends can shift rapidly based on economic conditions, which affects consumer behavior. High demand during peak construction seasons typically leads to increased prices, as suppliers may struggle to keep up. Conversely, during slower periods, prices may drop as factories aim to maintain sales volume.

It is also important to consider bulk purchasing options. Many factories offer discounted pricing for larger quantities, making it more cost-effective for contractors and businesses to acquire the materials needed for large-scale projects. Establishing direct relationships with manufacturers can lead to favorable pricing terms, benefiting both parties.

In conclusion, the pricing of 16.5g black annealed tie wire from factories is influenced by a multitude of factors, including raw material costs, manufacturing processes, geographical considerations, and market demand. For consumers and businesses alike, understanding these dynamics can lead to better purchasing decisions and ultimately, successful project outcomes. As the construction industry continues to grow and evolve, black annealed tie wire remains an essential component, with its pricing reflecting the complexities of the market.

-

The Durability and Versatility of Steel Wire

NewsJun.26,2025

-

The Best Iron Nails for Your Construction Projects

NewsJun.26,2025

-

Strengthen Your Projects with Durable Metal Stakes

NewsJun.26,2025

-

Get the Job Done Right with Duplex Nails

NewsJun.26,2025

-

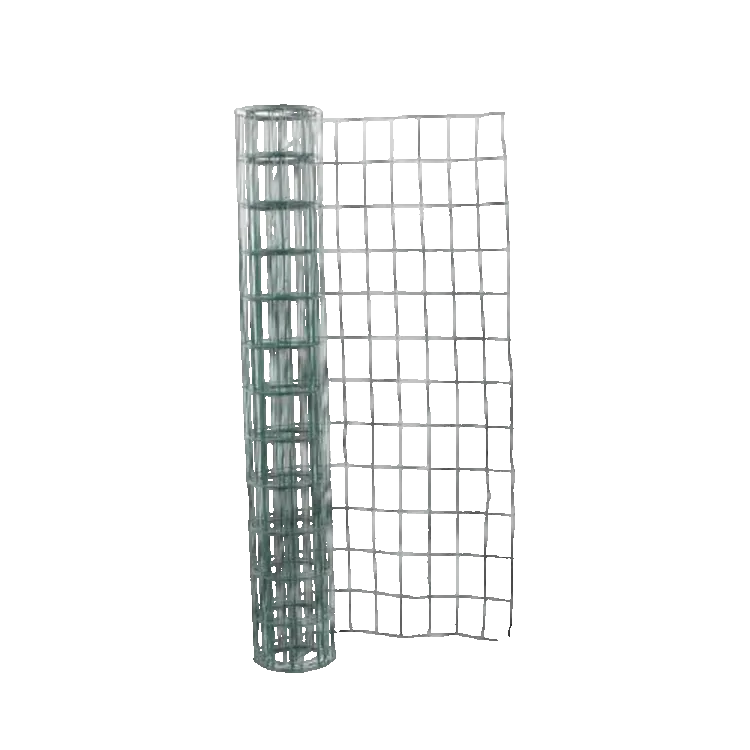

Explore the Versatility and Strength of Metal Mesh

NewsJun.26,2025

-

Enhance Your Security with Razor Wire

NewsJun.26,2025