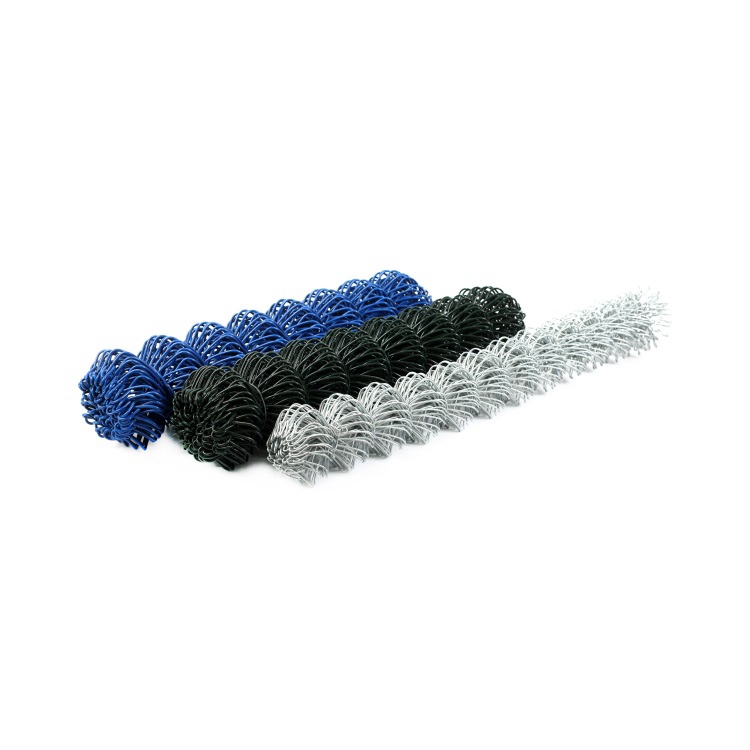

1.5mm Welded Wire Mesh Production and Quality Assurance from Leading Manufacturer

Understanding 1.5mm Welded Wire Mesh A Comprehensive Overview

Welded wire mesh has become a staple material across various industries due to its strength, versatility, and ease of use. Among the different specifications available, 1.5mm welded wire mesh stands out as an optimal choice for many applications. This article aims to provide insight into the characteristics, applications, and benefits of 1.5mm welded wire mesh, along with a glimpse into the manufacturing process.

What is 1.5mm Welded Wire Mesh?

1.5mm welded wire mesh is made from high-quality steel wires that are welded together at each intersection to form a robust grid system. The wire diameter of 1.5mm provides a balance between flexibility and strength, which makes it suitable for a variety of applications. Typically, this mesh is available in different dimensions, with a variety of mesh sizes to cater to specific needs. The most common configuration features a square or rectangular pattern.

Manufacturing Process

The manufacturing of welded wire mesh begins with the selection of raw materials, predominantly steel wires. These wires are drawn to the desired thickness and then cleaned to remove any contaminants, which ensures better adhesion during welding. The wires are then arranged in a grid format, where they are precisely spaced according to the required mesh size.

Welding occurs at the intersections using advanced machinery, which ensures uniform and strong welds. Once the mesh is formed, it undergoes quality control checks to ensure it meets industry standards. Subsequent processes might include galvanization or coating to enhance corrosion resistance and to improve durability, particularly in outdoor or industrial environments.

Applications of 1.5mm Welded Wire Mesh

The versatility of 1.5mm welded wire mesh makes it suitable for multiple applications across various sectors

1.5mm welded wire mesh manufacturer

1. Construction It is commonly used as reinforcement in concrete structures, providing additional strength and stability. 2. Fencing The mesh can be used for security fencing around properties, gardens, and farms, offering a sturdy barrier against intruders and animals. 3. Shelving and Storage It is often utilized in warehouses for shelving systems, allowing for better ventilation and visibility while ensuring a load-bearing capacity. 4. Animal Enclosures The mesh is perfect for creating safe habitats for pets, livestock, and wildlife, ensuring safety while providing necessary containment. 5. Decoration With its aesthetic appeal, welded wire mesh can also be used in artistic installations, landscaping, and modern architecture designs.

Benefits of 1.5mm Welded Wire Mesh

1. Durability The welded construction of the mesh coupled with the option for galvanization makes it highly resistant to wear, rust, and corrosion, allowing for prolonged use even in harsh environments. 2. Economic Efficiency This type of mesh is cost-effective due to its durability and minimal maintenance needs. Its long lifespan translates to lower overall expenses in replacement and repairs.

3. Customizable Manufacturers often provide customization options in terms of mesh size, panel size, and coatings, which makes it easy to meet specific project requirements.

4. Ease of Installation The lightweight design of the welded wire mesh simplifies transportation and installation processes, making it an efficient material for contractors and DIY enthusiasts alike.

5. Recyclable An eco-friendly option, welded wire mesh can be recycled at the end of its lifespan, contributing to sustainable building practices.

Conclusion

1.5mm welded wire mesh is an essential product in the realm of construction and design, thanks to its combination of strength, versatility, and economic efficiency. As industries evolve, the demand for quality welded wire mesh manufacturers continues to grow, driving innovation and improvements in product offerings. Whether for industrial, commercial, or residential purposes, 1.5mm welded wire mesh remains a smart choice for professionals and DIY projects alike.

-

The Durability and Versatility of Steel Wire

NewsJun.26,2025

-

The Best Iron Nails for Your Construction Projects

NewsJun.26,2025

-

Strengthen Your Projects with Durable Metal Stakes

NewsJun.26,2025

-

Get the Job Done Right with Duplex Nails

NewsJun.26,2025

-

Explore the Versatility and Strength of Metal Mesh

NewsJun.26,2025

-

Enhance Your Security with Razor Wire

NewsJun.26,2025