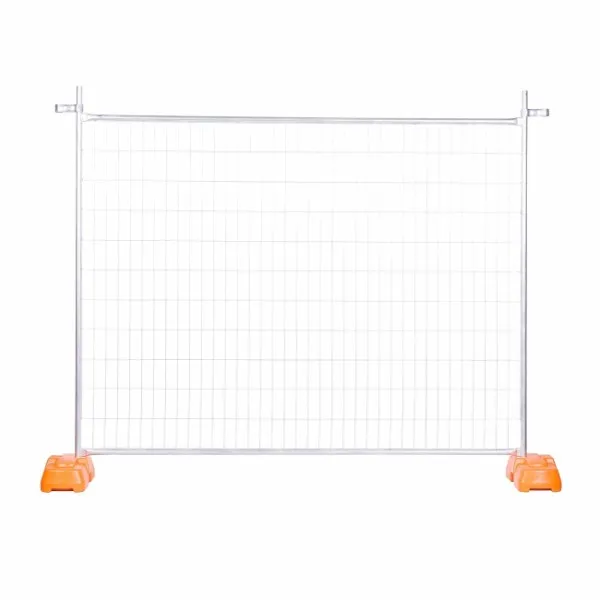

Welded Wire Mesh Temporary Fence: Durable, Secure & Easy Install

Introduction to Welded Wire Mesh Temporary Fence Solutions

The rapid pace of development in construction, infrastructure, and event management necessitates robust, versatile, and rapidly deployable security perimeters. Among the leading solutions, the Welded Wire Mesh Temporary Fence stands out as an indispensable asset. Engineered for both high-strength security and quick installation, these systems provide critical demarcation and protection in diverse environments. This article delves into the technical aspects, application versatility, and strategic advantages of modern welded wire mesh temporary fencing, offering an in-depth perspective for B2B decision-makers and technical professionals.

From large-scale industrial projects to public events, the demand for temporary fencing that can withstand environmental pressures, deter unauthorized access, and comply with safety regulations is paramount. We will explore the manufacturing excellence, performance metrics, and value proposition that make these fencing solutions a preferred choice across numerous sectors.

Manufacturing Process Flow of Welded Wire Mesh Temporary Fence

The production of a Welded Wire Mesh Temporary Fence is a meticulous process, ensuring durability, structural integrity, and ease of deployment. It typically involves several key stages, from raw material selection to final quality assurance. Our manufacturing adheres strictly to international standards such as ISO 9001 for quality management, ensuring every panel meets stringent performance criteria.

1. Material Selection and Preparation:

- High-Quality Steel Wire: We primarily utilize low-carbon steel wire or galvanized steel wire (Q195, Q235 grades) for its optimal balance of strength and ductility. For enhanced corrosion resistance, pre-galvanized wire is often selected, offering a zinc coating thickness typically ranging from 40-60 g/m².

- Steel Tubing for Frames: The frames are constructed from high-strength galvanized steel tubing, typically 32mm or 42mm in diameter, with wall thicknesses ranging from 1.5mm to 2.5mm. This provides the rigid support necessary for temporary installations.

2. Wire Mesh Welding:

- Precision Resistance Welding: Individual steel wires are fed into automated welding machines. These machines employ resistance welding to create strong, consistent welds at every intersection. This process ensures the mesh structure is robust and resistant to deformation.

- Mesh Aperture Control: Precise control over mesh apertures (e.g., 60x150mm, 75x150mm, 50x100mm) is maintained to meet various security and visibility requirements.

3. Frame Fabrication and Assembly:

- Tube Cutting and Bending: Galvanized steel tubes are cut to precise lengths and, where necessary, bent to form the perimeter of the fence panel.

- Welding the Frame: The cut and bent tubes are then welded together to form a rigid rectangular or square frame. MIG/MAG welding techniques are commonly used to ensure strong, durable joints.

- Mesh Integration: The pre-welded wire mesh is then securely welded to the inside of the fabricated steel frame. This can involve spot welding or continuous seam welding, depending on design specifications.

4. Surface Treatment:

- Hot-Dip Galvanization (HDG): For superior corrosion resistance, many panels undergo hot-dip galvanization after fabrication. This involves immersing the entire fence panel into molten zinc, creating a metallurgical bond and a thick, uniform zinc coating (typically >200 g/m²). This significantly extends service life, particularly in harsh outdoor environments.

- Powder Coating: Following galvanization, panels can be electrostatically powder coated with UV-resistant polymers (e.g., polyester or epoxy). This adds an extra layer of protection against weathering and allows for aesthetic customization with various RAL colors. The typical coating thickness is 80-120 microns.

5. Quality Control and Testing:

Throughout the process, rigorous quality control checks are performed. This includes:

- Material Inspection: Verification of raw material certifications (e.g., steel composition, zinc coating thickness).

- Dimensional Accuracy: Checking panel dimensions, mesh apertures, and wire diameters against design specifications.

- Weld Strength Testing: Destructive and non-destructive testing of weld points to ensure structural integrity.

- Coating Adhesion and Thickness: Adhesion tests (e.g., cross-hatch test) and thickness measurements (e.g., using eddy current gauges) for galvanized and powder-coated finishes. These tests comply with standards like ASTM A123/A123M for HDG and ASTM D3359 for powder coating.

- Corrosion Resistance Testing: Salt spray tests (ASTM B117) are performed on coated samples to predict long-term corrosion performance.

The expected service life of a hot-dip galvanized and powder-coated Welded Wire Mesh Temporary Fence often exceeds 10-15 years, even in challenging environments, due to these robust manufacturing and finishing processes.

Technical Specifications and Parameters

Understanding the precise technical parameters is crucial for selecting the appropriate Welded Wire Mesh Temporary Fence solution for a given application. The following table provides typical specifications for standard panels.

Standard Welded Wire Mesh Temporary Fence Panel Specifications

| Parameter | Description | Typical Values |

|---|---|---|

| Panel Height | Overall height of the fence panel | 1.8m, 2.1m, 2.4m |

| Panel Length | Overall width of the fence panel | 2.4m, 2.9m, 3.5m |

| Wire Diameter | Diameter of the steel wires forming the mesh | 3.0mm, 3.5mm, 4.0mm, 5.0mm |

| Mesh Opening (H x W) | Dimensions of the rectangular mesh apertures | 60x150mm, 75x150mm, 50x100mm |

| Frame Pipe Diameter | Outer diameter of the steel tubing for the frame | 32mm, 38mm, 42mm |

| Frame Pipe Wall Thickness | Thickness of the frame tubing wall | 1.5mm, 1.8mm, 2.0mm, 2.5mm |

| Surface Treatment | Corrosion protection and finish | Hot-Dip Galvanized, Powder Coated (over Galvanized) |

| Feet Type | Base supports for panels | Plastic/Concrete Block, Steel Feet |

| Clamps | Connectors for securing panels together | High-strength steel clamps |

These specifications allow for tailored solutions, considering factors such as wind load resistance, required security level, and aesthetic integration into the project environment. For instance, thicker wires and smaller mesh openings offer enhanced anti-climb properties, while larger mesh openings provide better visibility.

Application Scenarios and Industry Trends

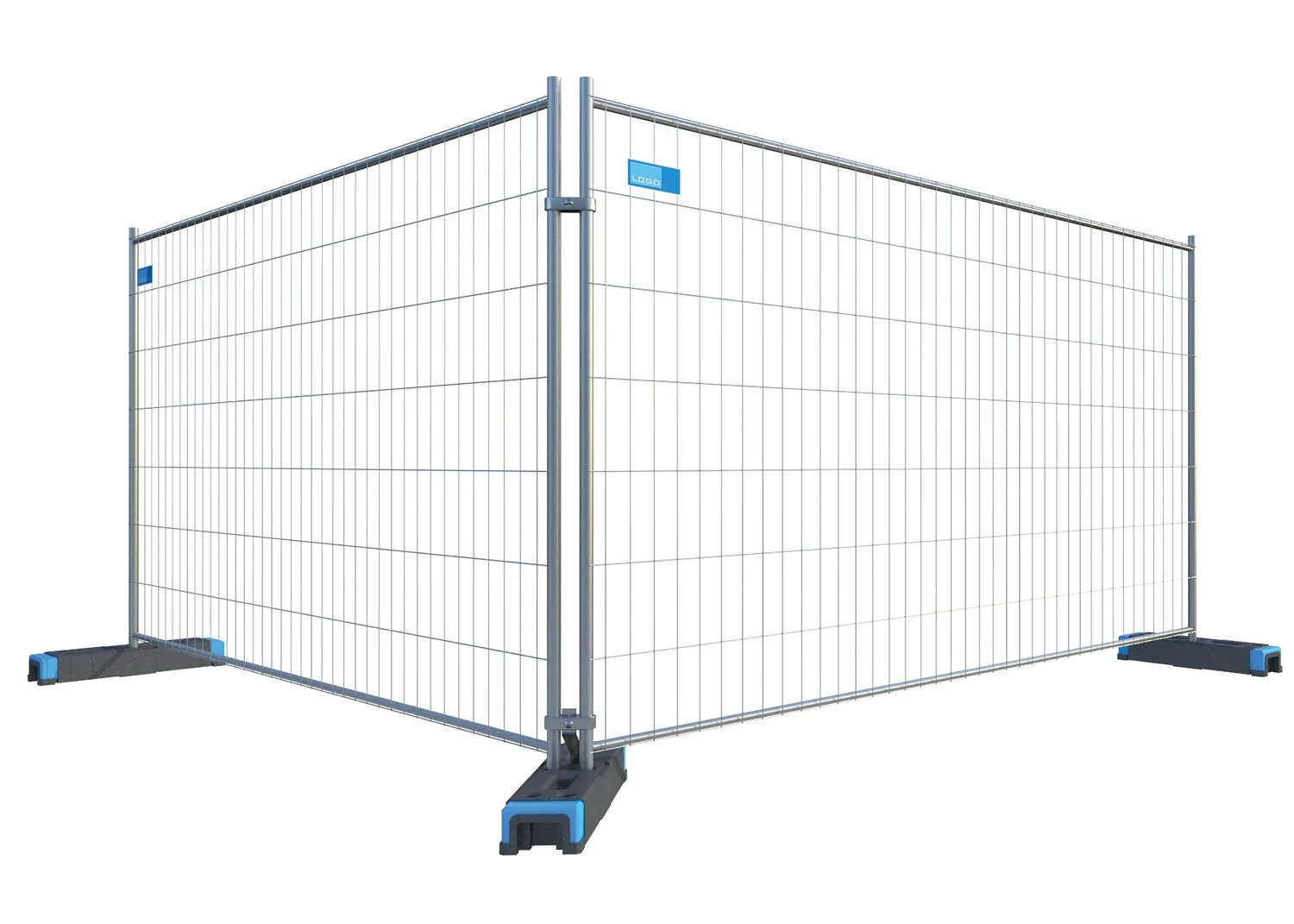

The versatility of Welded Wire Mesh Temporary Fence systems makes them ideal for a broad spectrum of applications across various industries. Modern trends emphasize not only security but also sustainability, rapid deployment, and adaptability.

Key Application Scenarios:

- Construction Sites: Essential for securing perimeters, delineating hazardous zones, and controlling access to active construction areas. Compliance with OSHA regulations often mandates robust temporary barriers.

- Event Management: From concerts and festivals to sporting events, these fences manage crowd flow, create VIP areas, and secure restricted zones. Their modular nature allows for quick setup and dismantling.

- Industrial Facilities (Petrochemical, Metallurgy): Used for short-term operational shifts, maintenance closures, or segregation of sensitive equipment. Their corrosion resistance (especially with HDG and powder coating) is critical in aggressive industrial atmospheres.

- Public Works and Infrastructure Projects (Water Supply & Drainage): Securing excavations, pipeline routes, and temporary diversion areas. The fences provide safety for both workers and the public.

- Emergency Services and Disaster Relief: Rapidly deployed to cordon off disaster zones, establish command centers, and control entry/exit during crises.

- Retail and Commercial Development: Securing vacant lots, temporary parking areas, or areas under renovation.

Industry Trends:

- Enhanced Security Features: Integration of anti-climb design elements (e.g., razor wire, barbed wire extensions, smaller mesh apertures) and compatibility with surveillance systems.

- Sustainability and Reusability: Increased demand for durable, reusable systems that minimize waste and reduce the environmental footprint of temporary installations. Our fences are designed for multiple deployments over many years.

- Modular and Rapid Deployment Systems: Focus on interlocking designs, lightweight yet robust construction, and tool-free installation to minimize labor costs and setup times.

- Aesthetic Integration: While functional, there's a growing need for temporary fencing that can blend into or even enhance the aesthetic of an event or site, often achieved through custom powder coating colors or branding attachments.

- Compliance with Local Regulations: As safety and environmental regulations become more stringent, manufacturers are continually refining designs to meet diverse international and local standards.

Technical Advantages and Performance Metrics

The core value proposition of a well-engineered Welded Wire Mesh Temporary Fence lies in its superior technical advantages, translating directly into operational efficiencies and enhanced safety.

Key Advantages:

- Exceptional Durability and Corrosion Resistance: Through multi-stage surface treatments like hot-dip galvanization (per ASTM A123/A123M) and subsequent powder coating, our fences exhibit outstanding resistance to rust, UV degradation, and chemical exposure. This extends their operational life significantly, even in coastal or industrial environments, leading to lower total cost of ownership.

- High Structural Integrity: The precision welding of both mesh and frame, coupled with high-strength steel components, provides excellent resistance to impact, bending, and deformation. This ensures the fence maintains its barrier function under stress.

- Rapid Deployment and Relocation: Designed for modularity, panels can be quickly connected using simple clamps, requiring minimal tools and labor. This significantly reduces setup and teardown times, offering substantial cost savings in project timelines.

- Versatile Configuration: The modular nature allows for flexible configurations to adapt to uneven terrain, different site layouts, and integration with gates, pedestrian access, and security enhancements.

- Enhanced Safety and Security: The robust construction acts as an effective deterrent against unauthorized entry. Options for anti-climb features further fortify the perimeter, crucial for high-security applications.

- Cost-Effectiveness: While initial investment might be higher than some rudimentary temporary barriers, the long lifespan, reusability, and low maintenance requirements of these fences offer superior long-term economic value.

Performance Metrics:

- Wind Load Resistance: Depending on panel design and footings, our systems are engineered to withstand wind speeds up to 100 km/h (approx. 62 mph) in accordance with relevant structural design codes.

- Pull-Out Strength of Clamps: Inter-panel clamps typically exhibit pull-out resistance exceeding 2000 N, ensuring secure connections.

- Galvanization Thickness: Hot-dip galvanized panels meet or exceed 200 g/m² zinc coating, providing decades of protection.

- ISO Certification: Our manufacturing processes are ISO 9001 certified, guaranteeing consistent quality and adherence to documented procedures.

Vendor Comparison and Customized Solutions

When selecting a provider for Welded Wire Mesh Temporary Fence, it's essential to compare not just product specifications but also manufacturing capabilities, certification, and customization options. Our extensive experience and vertically integrated production ensure high quality and flexibility.

Key Vendor Comparison Points:

| Feature/Aspect | Our Offering (FiveStar Metals) | Typical Competitor |

|---|---|---|

| Manufacturing Control | In-house, fully integrated production from raw material to finished product. | Often relies on outsourced welding or coating, potential for inconsistent quality. |

| Quality Standards & Certifications | ISO 9001, adherence to ASTM, ANSI, and local safety standards. Regular third-party audits. | May meet basic standards, less emphasis on comprehensive certification or external verification. |

| Customization Capability | Extensive customization for dimensions, mesh types, colors, gate integration, and accessories. | Limited to standard sizes and colors; specialized requests may not be feasible. |

| Surface Treatment Quality | Guaranteed hot-dip galvanization thickness (>200g/m²) and UV-stable powder coating. | Variable galvanization thickness, potentially lower quality powder coating leading to premature fading/peeling. |

| Lead Time & Fulfillment | Streamlined production, efficient logistics, reliable lead times for large and custom orders. | Potentially longer or less predictable lead times due to reliance on external suppliers. |

Customized Solutions:

Recognizing that no two projects are identical, we offer comprehensive customization for your Welded Wire Mesh Temporary Fence needs:

- Dimensions and Mesh Configurations: Tailored panel heights, lengths, wire diameters, and mesh apertures to meet specific security or visibility requirements.

- Surface Finishes: Beyond standard HDG and green/black powder coating, we offer a full range of RAL colors for aesthetic integration or corporate branding.

- Integrated Access Solutions: Custom-fabricated pedestrian gates, vehicle gates, and emergency exit panels designed to seamlessly integrate with the temporary fence line.

- Enhanced Security Features: Integration of barbed wire/razor wire extensions, anti-climb spiked tops, or provisions for CCTV mounting.

- Specialized Footings: Heavy-duty rubber blocks, concrete-filled bases, or in-ground sleeves for enhanced stability in high-wind zones or long-term temporary installations.

Our engineering team collaborates closely with clients to develop solutions that precisely match project specifications, ensuring optimal performance and compliance.

Application Case Studies

Case Study 1: Major Urban Infrastructure Project

Client: Tier-1 Construction Consortium

Challenge: Secure a 5km perimeter for a multi-year subway expansion project in a densely populated urban area, requiring robust security, public safety, and quick adaptability as construction phases evolved.

Solution: We supplied over 2000 linear meters of custom 2.4m high Welded Wire Mesh Temporary Fence panels with anti-climb mesh and heavy-duty concrete-filled plastic bases. Panels were hot-dip galvanized and powder-coated in a neutral grey to minimize visual impact. Integrated swinging gates were provided for vehicle and pedestrian access points. The modular design allowed for rapid redeployment to new sections of the project every 6-8 weeks.

Outcome: The system successfully maintained site security, prevented unauthorized access, and minimized public safety incidents over the project's multi-year duration. The durability of the fences allowed for multiple redeployments without significant degradation, leading to substantial cost savings compared to less robust alternatives. Feedback highlighted the ease of installation and the fences' ability to withstand urban environmental pressures.

Case Study 2: International Music Festival

Client: Leading Event Management Company

Challenge: Establish secure perimeters, crowd control barriers, and VIP enclosures for a 3-day music festival hosting over 100,000 attendees. Rapid setup and dismantling within a 48-hour window were critical, along with strong visual appeal.

Solution: We provided 3500 linear meters of 2.1m high Welded Wire Mesh Temporary Fence panels, selected for their quick-connect clamp system and robust design. Panels were powder-coated in a custom black finish to match the event's aesthetic and equipped with steel feet for stability on grass fields. Specialized entry/exit gates and branding banners were integrated seamlessly.

Outcome: The fencing system was deployed and dismantled efficiently within the tight operational window. It effectively managed crowd flow, secured restricted artist and backstage areas, and provided a safe environment for attendees. The aesthetic finish contributed positively to the overall event experience, demonstrating the versatility of welded wire mesh temporary fences beyond purely industrial applications.

Trustworthiness and Support

Our commitment extends beyond product delivery to ensuring a seamless customer experience, underpinned by transparency and robust support infrastructure.

Frequently Asked Questions (FAQ):

- Q: What is the typical lead time for a standard order?

- A: For standard Welded Wire Mesh Temporary Fence panels, our typical lead time is 2-4 weeks from order confirmation, depending on quantity and current production schedules. Custom orders may require additional time for design and specialized fabrication.

- Q: What are your warranty commitments?

- A: We offer a comprehensive 10-year warranty on materials and workmanship for our hot-dip galvanized and powder-coated fence panels against manufacturing defects and premature corrosion under normal use conditions. Specific terms are outlined in our warranty documentation.

- Q: Can your fences be installed on uneven terrain?

- A: Yes, our modular system design and variety of footing options (e.g., adjustable bases) allow for effective installation on uneven or sloping ground, maintaining security and stability.

- Q: Do you provide installation guidelines or support?

- A: Absolutely. We provide detailed installation manuals and technical drawings. For larger projects or complex installations, our technical support team is available for consultation and, if necessary, on-site assistance.

Lead Time & Fulfillment:

Our robust supply chain management and advanced manufacturing facilities enable us to maintain reliable lead times. We offer transparent communication throughout the order fulfillment process, from production updates to shipping logistics. Expedited options may be available for urgent requirements, subject to project specifics and current capacity.

Warranty & After-Sales Support:

Our products are backed by industry-leading warranties, reflecting our confidence in their quality and longevity. Beyond the initial purchase, our dedicated after-sales support team is readily available to assist with any technical queries, spare parts, or guidance on maintenance to ensure your Welded Wire Mesh Temporary Fence continues to perform optimally throughout its extensive service life.

For further inquiries or to discuss your specific project needs, please contact our sales and technical support team via the details provided on our website. We are committed to providing expert advice and tailored solutions.

References

- ASTM International. (2020). ASTM A123/A123M-17: Standard Specification for Zinc (Hot-Dip Galvanized) Coatings on Iron and Steel Products.

- ISO. (2015). ISO 9001: Quality management systems – Requirements.

- Occupational Safety and Health Administration (OSHA). (2023). Safety and Health Regulations for Construction.

- Galvanizers Association. (2021). The Performance of Hot Dip Galvanizing.

-

Discount 16 d Common Nails - Bulk, Durable, Fast Shipping

NewsNov.17,2025

-

Finish Nails - Durable, Rust-Resistant, Clean Countersink

NewsNov.17,2025

-

Barbed Wire: Galvanized, High-Tensile Security Fencing

NewsNov.17,2025

-

Discount 16 d Common Nails – Bulk, Durable, OEM Options

NewsNov.17,2025

-

Welded Steel Tube Temporary Fence – Galvanized, Durable

NewsNov.04,2025

-

Barbed Wire – High-Tensile, Galvanized, Bulk & Fast Shipping

NewsNov.04,2025