Woven Mesh Temporary Fence: Secure & Portable Site Barriers

Introduction to Advanced Temporary Fencing Solutions

In dynamic operational environments, effective site management, public safety, and asset protection are paramount. This necessity drives the demand for robust, deployable, and reliable perimeter control systems. Among the leading solutions engineered for this purpose is the Woven Mesh Temporary Fence. This article delves into the technical intricacies, application versatility, and strategic advantages of this critical infrastructure component, designed to meet the rigorous demands of B2B sectors.

From urban construction sites to large-scale event management and critical infrastructure projects, the woven mesh system offers a blend of security, visibility, and operational flexibility unmatched by conventional barriers. We will explore its manufacturing precision, adherence to international standards, and its quantifiable benefits in diverse industrial applications.

Current Industry Trends in Perimeter Security

The global market for temporary fencing solutions is experiencing significant growth, driven by an increase in construction activities, major public events, and heightened security concerns. According to recent market analysis, the global perimeter security market is projected to reach approximately $30 billion by 2027, with temporary fencing playing a crucial role in its expansion. Key trends include:

- Sustainability Focus: Increasing demand for recyclable materials and durable, reusable fencing systems to minimize environmental impact and reduce lifecycle costs.

- Enhanced Security Features: Integration of anti-climb designs, robust locking mechanisms, and compatibility with surveillance systems.

- Rapid Deployment & Flexibility: Emphasis on systems that can be quickly installed, reconfigured, and dismantled without specialized tools or extensive labor, crucial for dynamic project timelines.

- Corrosion Resistance: Preference for galvanized or PVC-coated solutions to withstand harsh environmental conditions, extending service life and reducing maintenance.

- Digital Integration: While not directly for the fence itself, data-driven project management increasingly influences the selection and deployment logistics of temporary fencing.

These trends underscore the evolving requirements for temporary barriers, making the Woven Mesh Temporary Fence an increasingly preferred choice due to its inherent strength, adaptability, and cost-effectiveness over its operational lifespan.

Manufacturing Process of Woven Mesh Temporary Fence

The production of a Woven Mesh Temporary Fence involves a multi-stage, precision-controlled process to ensure durability, structural integrity, and long-term performance. Adherence to international standards such as ISO 9001 for quality management and ASTM A641 for metallic-coated carbon steel wire is critical throughout.

Process Flow:

1. Material Selection

High-quality carbon steel wire (e.g., Q195, Q235) is selected based on tensile strength and ductility requirements. For enhanced corrosion resistance, pre-galvanized wire or hot-dip galvanized wire is typically used, meeting standards like ISO 1461.

2. Wire Drawing & Galvanization

Raw steel rods are drawn to the specified wire gauge. For hot-dip galvanization, wires are cleaned, fluxed, and immersed in molten zinc at approximately 450°C, forming a metallurgical bond that provides superior corrosion protection (zinc coating thickness typically 60-80 g/m²).

3. Mesh Weaving

Galvanized wires are fed into automatic weaving machines, interlacing them to form the desired mesh pattern (e.g., diamond or square). This process ensures consistent mesh opening size and uniform tension, critical for panel stability.

4. Frame Fabrication

The fence panel frames are typically constructed from pre-galvanized steel pipes (e.g., 32mm or 42mm OD) that are cut, bent, and welded. All welds are meticulously cleaned and often re-galvanized or painted with zinc-rich primer to maintain corrosion resistance.

5. Panel Assembly & Finishing

The woven mesh is securely attached to the fabricated frame using techniques such as welding, tie wires, or specialized clamps, ensuring tautness and rigidity. Panels may then undergo additional treatments like PVC coating for enhanced aesthetics and corrosion protection.

6. Quality Control & Testing

Each batch undergoes rigorous quality checks, including visual inspection for defects, measurement of dimensions (panel height, width, mesh size), coating thickness testing (e.g., using XRF analysis), and destructive testing for weld strength and material integrity. Conformance to standards like ANSI B11.1 for safety is also verified.

This meticulous manufacturing process ensures that the finished Woven Mesh Temporary Fence delivers an estimated service life of 7-15 years, depending on environmental conditions and coating type. Target industries include petrochemical, metallurgy, civil engineering, water supply & drainage, and general construction, where advantages such as corrosion resistance, ease of deployment, and high wind load resistance are critical.

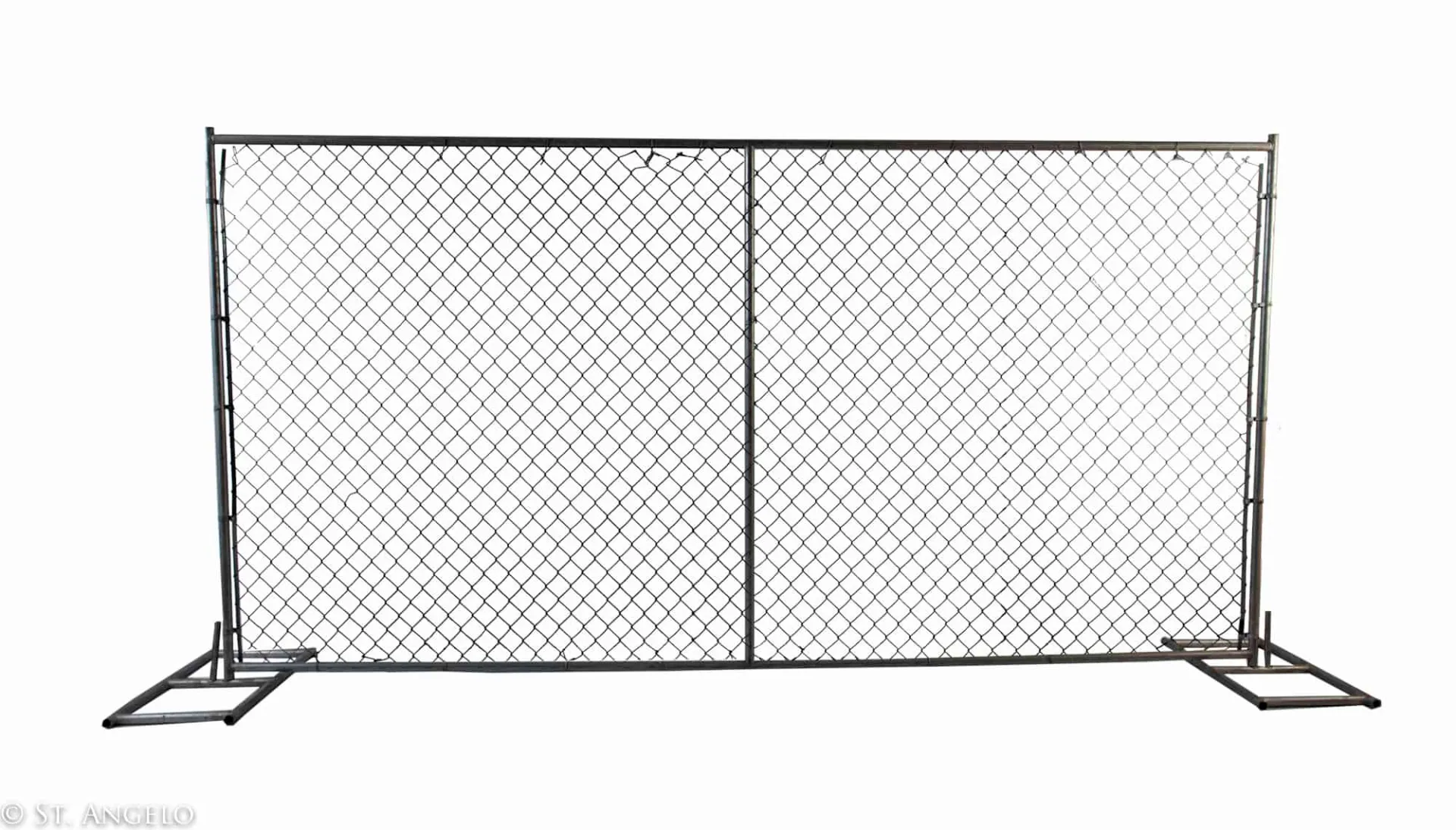

Figure 1: Illustration of a securely installed Woven Mesh Temporary Fence panel.

Technical Specifications and Parameters

Understanding the precise technical parameters of a Woven Mesh Temporary Fence is crucial for project managers and procurement specialists to ensure optimal performance and compliance. The specifications define the structural integrity, security level, and suitability for various environmental conditions.

Typical Product Specifications:

| Parameter | Specification Range | Notes |

|---|---|---|

| Panel Height | 1.8m to 2.4m (approx. 6ft to 8ft) | Common heights for security & site demarcation. |

| Panel Width | 2.1m to 2.9m (approx. 7ft to 9.5ft) | Standard panel lengths for ease of transport & installation. |

| Wire Diameter | 2.5mm to 4.0mm (approx. 11 to 8 gauge) | Dictates mesh strength and anti-cut resistance. |

| Mesh Opening Size | 50mm x 50mm to 60mm x 150mm | Smaller openings for increased security (anti-climb), larger for visibility. |

| Frame Material | Galvanized steel pipe (e.g., Q235) | Typically round (OD 32mm, 42mm, 48mm) or square (30x30mm). |

| Surface Treatment | Hot-dip galvanized, Pre-galvanized, PVC Coated | Corrosion resistance & aesthetic appeal. |

| Feet Type | Plastic filled with concrete, Steel feet | Ensures stability, especially in windy conditions. |

| Tensile Strength | ≥ 400 MPa (wire) | Meets ASTM A641 standards for steel wire. |

| Zinc Coating Thickness | ≥ 45 g/m² (pre-galv), ≥ 200 g/m² (hot-dip galv) | Critical for long-term corrosion protection. |

These detailed specifications allow for precise material selection and configuration, enabling the deployment of a Woven Mesh Temporary Fence system that is perfectly tailored to project requirements, environmental factors, and regulatory compliance, ensuring optimal safety and operational efficiency.

Application Scenarios and Industry Use Cases

The adaptability and robust design of the Woven Mesh Temporary Fence make it an indispensable asset across a broad spectrum of industries. Its capability to rapidly establish secure perimeters, control access, and define boundaries is critical in transient or evolving operational landscapes.

- Construction Sites: Essential for public safety and site security, preventing unauthorized access to hazardous areas, containing debris, and managing vehicle and pedestrian traffic flow. Meets OSHA and local building code requirements for temporary site enclosures.

- Event Management: From large music festivals and sporting events to public exhibitions, these fences define spectator areas, create secure VIP zones, manage crowd ingress/egress, and protect restricted access points. Their modular nature allows for quick setup and removal.

- Emergency & Disaster Relief: Rapid deployment for securing affected areas, establishing command centers, and controlling access to disaster zones. Their portability is invaluable in humanitarian operations.

- Mining & Quarry Operations: Delineating dangerous blasting zones, protecting equipment, and establishing exclusion zones for workers and the public. The fences withstand harsh industrial environments.

- Utility & Infrastructure Projects: Securing excavations, power sub-stations, pipeline routes, and roadworks. Ensures the safety of both workers and the public from ongoing operations.

- Retail & Commercial Renovations: Temporarily sectioning off areas undergoing renovation, ensuring minimal disruption to business operations while maintaining safety.

Figure 2: Woven Mesh Temporary Fence effectively delineating a construction zone.

In each of these scenarios, the system’s robust construction, ease of assembly, and effective containment capabilities prove invaluable, contributing to enhanced safety protocols and operational efficiency.

Technical Advantages and Performance Metrics

The technical advantages of a Woven Mesh Temporary Fence are numerous, distinguishing it from alternative temporary barrier solutions. These advantages are rooted in its engineering design, material science, and manufacturing quality, leading to superior performance in critical applications.

- Superior Strength-to-Weight Ratio: Utilizing high-tensile steel wire and robust galvanized frames, these fences offer significant resistance to impacts and external forces while remaining relatively lightweight for transport and installation.

- Exceptional Corrosion Resistance: Hot-dip galvanization, conforming to ISO 1461, provides a thick, metallurgically bonded zinc layer that offers anodic and barrier protection against rust, significantly extending service life even in harsh coastal or industrial environments. PVC coating adds an additional layer of protection and aesthetic appeal.

- Enhanced Stability & Wind Load Resistance: Designed with wide, stable bases (e.g., concrete-filled plastic blocks or heavy-duty steel feet) and often incorporating additional bracing, these systems can withstand significant wind loads (e.g., tested up to 80-100 km/h with appropriate ballast), crucial for large outdoor installations.

- Rapid Deployment & Reusability: Modular panel design allows for quick assembly and disassembly using simple clamping systems. This significantly reduces labor costs and time for project mobilization and demobilization, enabling multiple reuses across different projects.

- Anti-Climb and Security Features: Tightly woven mesh patterns (e.g., 50x50mm) minimize foot and hand holds, deterring unauthorized climbing. Integration with barbed wire extensions or anti-tamper fixings further enhances security.

- Cost-Effectiveness Over Lifecycle: While initial investment might be higher than flimsy alternatives, the long service life, minimal maintenance requirements, and reusability of woven mesh systems translate into a lower total cost of ownership (TCO) over extended periods.

These advantages collectively position the Woven Mesh Temporary Fence as a premier choice for professionals seeking a high-performance, reliable, and economically viable temporary fencing solution.

Vendor Comparison and Selection Criteria

Selecting the right supplier for Woven Mesh Temporary Fence systems is paramount to ensuring project success, budget adherence, and long-term satisfaction. While product specifications provide a technical baseline, vendor capabilities and commitments significantly influence the overall value proposition.

Key Comparison Factors:

| Factor | Description | Impact on Project |

|---|---|---|

| Material Quality & Certifications | Adherence to international standards (ISO, ASTM, ANSI) for steel, galvanization, and welding. Availability of material test certificates (MTCs). | Ensures product durability, compliance with regulations, and reduces risk of premature failure. |

| Manufacturing Expertise & Capacity | Years of experience, production volume, quality control processes (e.g., 5-stage QC), and ability to handle large orders efficiently. | Reliable lead times, consistent product quality, and ability to scale for project demands. |

| Customization Capabilities | Ability to tailor panel dimensions, mesh types, coating options, color, and incorporate specialized accessories like gates, signage, or privacy screens. | Ensures the fencing solution perfectly fits unique site requirements and branding needs. |

| Logistics & Lead Time | Efficiency in order processing, packaging, shipping, and adherence to promised delivery schedules. Global shipping experience. | Minimizes project delays and ensures timely availability of materials on-site. |

| After-Sales Support & Warranty | Technical assistance, clear warranty policies, and responsiveness to inquiries or issues. | Provides peace of mind, protection of investment, and ongoing operational support. |

Prospective buyers should request comprehensive documentation, including detailed product datasheets, quality certifications, and client testimonials, to make an informed decision. Partnering with a reputable vendor with proven experience in industrial-grade temporary fencing solutions is crucial for maximizing project efficiency and safety.

Customized Solutions for Unique Demands

While standard configurations of Woven Mesh Temporary Fence panels address most common requirements, many B2B projects necessitate tailored solutions to meet specific site constraints, security levels, or branding objectives. Leading manufacturers offer comprehensive customization capabilities to ensure optimal fit and performance.

Customization Options Include:

- Dimensions: Custom panel heights and widths to perfectly match architectural designs, topography, or specific security clearance requirements.

- Mesh Configuration: Variations in wire gauge and mesh opening size for enhanced anti-climb properties, increased visibility, or specific debris containment needs.

- Surface Finishes: Beyond standard galvanization, options include specific RAL colors for PVC coating to match corporate branding or aesthetic requirements, and specialized anti-corrosion treatments for extreme environments.

- Integrated Access Points: Design and fabrication of custom pedestrian gates, vehicle gates, and emergency access points, complete with various locking mechanisms and automation options.

- Accessories & Attachments: Integration of privacy screens (wind/sight blocking), barbed wire extensions, security cameras, access control systems, and custom signage mounts.

- Base Systems: Development of specialized base plates or anchoring systems for unique ground conditions, such as uneven terrain or applications requiring non-invasive installation.

Engaging with a manufacturer that possesses strong engineering and design capabilities ensures that customized solutions are not only precisely fabricated but also maintain the high standards of safety, durability, and compliance expected of industrial-grade temporary fencing.

Application Case Studies

Case Study 1: Major Urban Infrastructure Project

A leading construction firm was tasked with a multi-year urban railway expansion project, requiring extensive temporary fencing along busy public thoroughfares. The project demanded high-visibility, anti-climb fencing that could be rapidly deployed and relocated as construction phases progressed. They opted for a galvanized Woven Mesh Temporary Fence system.

- Challenge: Secure numerous access points, protect pedestrians from heavy machinery, and minimize visual obstruction for local businesses.

- Solution: Deployed 2.4m high woven mesh panels with 50x100mm mesh openings and robust concrete-filled feet for superior stability. Integrated vehicular and pedestrian gates were custom-fabricated.

- Outcome: The system provided effective perimeter security for over 15 km, successfully managing public interaction with the site. The ease of relocation saved an estimated 20% in labor costs compared to fixed alternatives over the project's lifespan, contributing to overall safety ratings being consistently excellent.

Case Study 2: International Music Festival Perimeter

An event management company organized a large-scale international music festival expected to host over 100,000 attendees. A critical requirement was to establish a secure, crowd-control perimeter for the event grounds within a tight setup timeframe.

- Challenge: Create a secure, aesthetically pleasing perimeter over 5 km, with numerous entry/exit points, capable of withstanding crowd pressures and deterring unauthorized entry. Rapid installation and dismantling were key.

- Solution: Utilized PVC-coated (black) woven mesh panels with a 60x150mm mesh size for optimal crowd visibility and aesthetic integration. Panels were quickly connected using heavy-duty clamps, and over 50 temporary gates were installed.

- Outcome: The entire perimeter was installed within 48 hours. The fence system provided excellent crowd control and security, contributing to zero unauthorized entries into restricted areas. Post-event, the modular design facilitated quick dismantling and efficient storage for future events.

Figure 3: Woven Mesh Temporary Fence securing an outdoor event perimeter.

Frequently Asked Questions (FAQ)

Q: What is the typical lifespan of a Woven Mesh Temporary Fence?

A: With proper galvanization (e.g., hot-dip galvanized) and maintenance, a Woven Mesh Temporary Fence can last 7 to 15 years, or even longer in less corrosive environments. PVC coating can further extend this lifespan and provide additional UV protection.

Q: Are these fences easy to install and relocate?

A: Yes, their modular design, combined with universal clamps and portable feet, makes them exceptionally easy to install, dismantle, and relocate without specialized tools or extensive training. A typical panel can be set up by two workers in minutes.

Q: Can Woven Mesh Temporary Fences withstand high winds?

A: When properly installed with adequate base weights (e.g., concrete-filled feet) and potentially additional bracing, these fences are designed to withstand significant wind loads. Manufacturers typically provide guidelines for wind resistance ratings based on installation methods.

Q: What are the common applications for these fences?

A: They are widely used in construction sites, public events, mining operations, roadwork, utility projects, and any scenario requiring temporary perimeter security, crowd control, or hazard demarcation.

Q: Is customization available for specific project needs?

A: Absolutely. Custom dimensions, mesh sizes, coatings (including RAL colors), integrated gates, and various accessories can be tailored to meet unique project requirements. Consult with your supplier for detailed customization options.

Lead Time, Warranty, and Customer Support

Lead Time & Fulfillment:

Typical lead times for standard Woven Mesh Temporary Fence orders range from 2 to 4 weeks, depending on order volume and current production schedules. Custom orders may require additional time for design and fabrication, usually 4 to 6 weeks. Expedited options are often available for urgent requirements. Our robust logistics network ensures efficient global shipping, with comprehensive tracking provided for all consignments. We prioritize clear communication regarding fulfillment milestones from order confirmation to final delivery.

Warranty Commitments:

We stand behind the quality of our Woven Mesh Temporary Fence products. A standard warranty of 5 to 10 years is offered on material and workmanship, covering defects in galvanization and structural integrity under normal use and recommended installation practices. Specific warranty terms will be provided with each quotation, reflecting the product type and chosen finishes. This commitment underscores our confidence in the long-term durability and performance of our fencing solutions.

Customer Support & After-Sales Service:

Our dedicated customer support team provides comprehensive technical assistance, from initial project consultation and product selection to post-installation queries. We offer expert guidance on installation best practices, maintenance, and troubleshooting. Our goal is to ensure seamless integration of our temporary fencing systems into your projects and to provide ongoing support throughout their operational lifespan. Contact our sales and technical departments for any inquiries or support needs.

Conclusion

The Woven Mesh Temporary Fence represents a pinnacle of temporary perimeter security, combining robust engineering with versatile application. Its meticulous manufacturing process, adherence to international quality standards, and inherent advantages in durability, reusability, and ease of deployment make it an unparalleled choice for B2B applications across construction, event management, and infrastructure development. By understanding its technical specifications and leveraging customized solutions, businesses can achieve optimal site safety, operational efficiency, and long-term cost-effectiveness.

Investing in high-quality woven mesh fencing is a strategic decision that safeguards assets, personnel, and public safety while streamlining project logistics. As industries continue to evolve, the demand for adaptable and resilient temporary fencing solutions like this will only grow, cementing its role as a fundamental component of modern site management.

References

- ISO (International Organization for Standardization). ISO 9001:2015 - Quality management systems — Requirements. www.iso.org

- ASTM International. ASTM A641/A641M-09 Standard Specification for Zinc–Coated (Galvanized) Carbon Steel Wire. www.astm.org

- OSHA (Occupational Safety and Health Administration). Safety and Health Regulations for Construction. www.osha.gov

- Galvanizers Association. Hot Dip Galvanizing - A Guide for Specifiers. www.galvanizing.org.uk

- MarketsandMarkets. Perimeter Security Market - Global Forecast to 2027. www.marketsandmarkets.com

-

Discount 16 d Common Nails - Bulk, Durable, Fast Shipping

NewsNov.17,2025

-

Finish Nails - Durable, Rust-Resistant, Clean Countersink

NewsNov.17,2025

-

Barbed Wire: Galvanized, High-Tensile Security Fencing

NewsNov.17,2025

-

Discount 16 d Common Nails – Bulk, Durable, OEM Options

NewsNov.17,2025

-

Welded Steel Tube Temporary Fence – Galvanized, Durable

NewsNov.04,2025

-

Barbed Wire – High-Tensile, Galvanized, Bulk & Fast Shipping

NewsNov.04,2025