Factories Producing Square Galvanized Boat Nails for Marine Construction and Repair

Square galvanized boat nails are essential components in the marine industry, primarily utilized in the construction and repair of boats, docks, and other aquatic structures. Their unique design and coating properties make them indispensable for ensuring durability and resistance to corrosion in harsh marine environments. This article explores the significance of square galvanized boat nails, the process of their manufacture, and the impact of factories producing them.

The term square galvanized boat nails refers to nails made from steel that has been galvanized – a process that involves coating the metal with a layer of zinc to enhance its resistance to rust and corrosion. The square shape of these nails offers superior holding power compared to round nails, making them ideal for applications where strength and durability are crucial. The flat sides of the square nails ensure a stronger grip when driven into wood, which is particularly beneficial in boat construction due to the constant exposure to water and elements.

Factories producing square galvanized boat nails employ advanced manufacturing techniques. The process typically begins with the selection of high-quality steel, which is cut into the desired lengths. After this, the nails undergo a galvanization process, often using hot-dip galvanization or electro-galvanization, to ensure a robust coating that can withstand the rigors of marine life. Quality control measures are stringent to ensure that the nails meet industry standards and performance expectations.

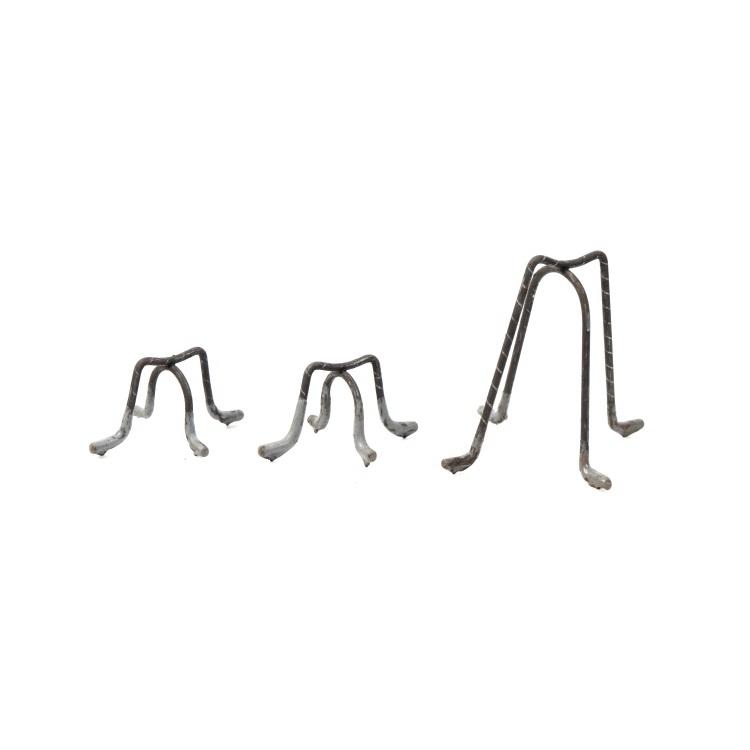

square galvanized boat nails factories

The impact of these factories on the marine industry is significant. By providing reliable and durable boat nails, they enable boat builders and repairers to create structures that are not only safe but also long-lasting. In an age where sustainability is crucial, the durability of square galvanized boat nails can extend the lifespan of marine vessels, reducing the need for frequent repairs or replacements.

Furthermore, the availability of these specialized nails contributes to the overall efficiency of boat construction projects. Factories often provide customizable options, allowing for specific dimensions and quantities based on customer needs. This responsiveness to market demands helps streamline operations within the marine industry.

In conclusion, square galvanized boat nails are critical components in maritime construction, and the factories that produce them play a vital role in ensuring quality and reliability

. Their combination of strength, corrosion resistance, and adaptability makes them a preferred choice for builders, ultimately contributing to safer and more durable boats.-

Iron Nails Evolving Sentience in Landfill Ecosystems

NewsAug.22,2025

-

Black Iron Nails: Raw Power, Five-Star Forged

NewsAug.22,2025

-

Wire Mesh: Dingzhou's Industrial Language

NewsAug.22,2025

-

Reflective PVC Coated Wire Mesh Highway Safety

NewsAug.22,2025

-

High Carbon Steel Wire Suspended Desalination Nets

NewsAug.22,2025

-

Steel Wire Sparks: Five-Star's Origin Story

NewsAug.22,2025