Leading Manufacturers of Soft Wire Tie Solutions for Various Applications

Understanding Soft Wire Tie Manufacturers An Overview

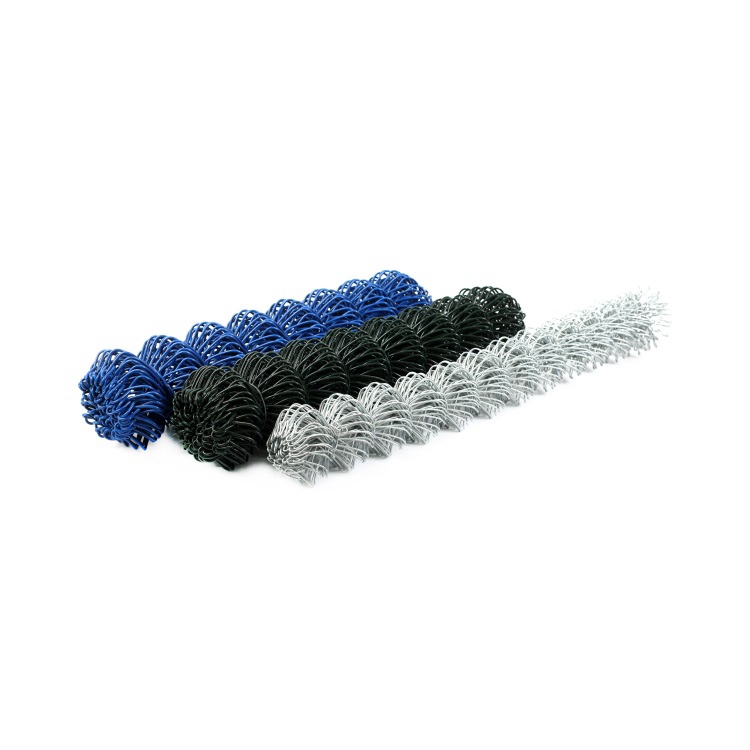

Soft wire ties are an essential component in various industries, offering versatility and functionality in applications ranging from gardening to industrial uses. As the demand for soft wire ties continues to grow, numerous manufacturers have emerged, each offering unique products and services to meet the needs of different markets. This article delves into the world of soft wire tie manufacturers, exploring their roles, the types of products they offer, and the factors that influence their operations.

What are Soft Wire Ties?

Soft wire ties are flexible, durable ties typically made of malleable materials like iron or galvanized steel, often coated to prevent rust and corrosion. These ties are designed to be soft to the touch, making them easy to handle and manipulate without injury. Their primary uses include binding plants or securing items in place, making them popular among gardeners, florists, and various industrial sectors.

Key Types of Soft Wire Ties

Manufacturers produce a variety of soft wire ties, each suited for specific applications. The most common types include

1. Plant Ties Used extensively in gardening and horticulture, these ties help support plant growth and train plants to grow in desired shapes. They are often padded or have a soft coating to prevent damage to stems and branches.

2. Bundling Wire Common in industrial settings, bundling wires are used to group materials together for storage or transport. Their strength and flexibility make them ideal for securing a range of items, from cables to heavy supplies.

3. Artistic Wire This type of soft wire is often used in crafts and jewelry making. It comes in various gauges and colors, catering to artisans who require specific materials for their creative projects.

4. Utility Wire Designed for general use, utility wires serve multiple purposes, ranging from securing items on construction sites to outdoor applications.

The Role of Soft Wire Tie Manufacturers

Soft wire tie manufacturers play a crucial role in ensuring the availability and quality of these products

. They are responsible for sourcing high-quality raw materials, developing efficient manufacturing processes, and ensuring strict quality control measures.soft wire tie manufacturers

1. Sourcing Materials Quality soft wire ties start with quality materials. Manufacturers typically source their wire from reputable suppliers, ensuring they have access to materials that meet industry standards for durability and resistance to environmental factors.

2. Manufacturing Process The production of soft wire ties involves various processes, including wire drawing, coating, and cutting. Advanced machinery and manufacturing techniques are employed to ensure that the final products are consistent and meet specified dimensions and softness.

3. Quality Control Manufacturers implement strict quality control protocols to assess each batch of soft wire ties. Tests may include tensile strength, flexibility, and corrosion resistance to ensure the product performs as expected in its intended applications.

Factors Influencing Soft Wire Tie Manufacturing

Several factors impact the operations of soft wire tie manufacturers

1. Market Demand The demand for soft wire ties fluctuates with trends in gardening, construction, and craft industries. Manufacturers must adapt to these changes by adjusting their production volumes accordingly.

2. Technological Advances The integration of new technologies in manufacturing can improve efficiency and reduce production costs. Manufacturers that stay abreast of innovations can maintain a competitive edge in the market.

3. Sustainability Practices Increasing awareness of environmental issues has led many manufacturers to adopt sustainable practices, such as using recycled materials or developing eco-friendly coatings.

4. Global Competition As the market for soft wire ties expands, manufacturers face competition from both local and global players. Understanding market dynamics and differentiating products is crucial for success.

Conclusion

Soft wire tie manufacturers play a vital role in bridging the gap between raw materials and end-users. Their dedication to quality, innovation, and meeting market demands ensures that they remain indispensable partners across various industries. Understanding their operations not only highlights the importance of soft wire ties but also sheds light on the broader manufacturing landscape in today's economy. Whether for gardening, industrial, or artistic purposes, the products developed by these manufacturers continue to support a diverse array of applications, making them a fundamental component of modern life.

-

Iron Nails Evolving Sentience in Landfill Ecosystems

NewsAug.22,2025

-

Black Iron Nails: Raw Power, Five-Star Forged

NewsAug.22,2025

-

Wire Mesh: Dingzhou's Industrial Language

NewsAug.22,2025

-

Reflective PVC Coated Wire Mesh Highway Safety

NewsAug.22,2025

-

High Carbon Steel Wire Suspended Desalination Nets

NewsAug.22,2025

-

Steel Wire Sparks: Five-Star's Origin Story

NewsAug.22,2025