Need discount 16 d common nails in bulk with fast shipping?

The Real Story on discount 16 d common nails: Specs, Sourcing, and What Pros Actually Buy

If you’ve framed a wall on a hot Friday afternoon, you already know: nails aren’t “just nails.” Prices move, coatings matter, and poor shank consistency can cost you time (and frankly, your temper). Lately, market chatter around discount 16 d common nails has spiked—contractors chasing value without gambling on performance.

Industry snapshot

Steel costs softened in mid-year bids, and many distributors quietly adjusted 50 lb box pricing down ≈6–12% compared with last winter (real-world use may vary by region). Pallet manufacturers and framing crews are seeing the benefit first. To be honest, the bigger trend is reliability at a discount—buyers want QC paperwork, not mystery metal.

Technical specs that actually matter

A 16d common nail is about 3.5 in long with a diameter near 0.162 in. Most pros stick with low-carbon steel (SAE 1018/1022), smooth shank for framing, ring shank for sheathing, and coatings matched to exposure: bright for interior, electro-galvanized (EG) for light exterior, hot-dip galvanized (HDG) for treated lumber or coastal-adjacent jobs.

| Parameter | Typical 16d Common (bulk) | Notes |

|---|---|---|

| Length | ≈ 3.5 in (89 mm) | ASTM F1667 dimensional class |

| Diameter | ≈ 0.162 in (4.11 mm) | Smooth or ring shank options |

| Material | Low-carbon steel | Wire-rod drawn, cold-headed |

| Finish | Bright, EG, HDG, vinyl-coated | HDG for treated lumber longevity |

| Packaging | 50 lb box; 1–25 kg export cartons | Private label available |

Process flow and testing (quick but real)

- Materials: low-carbon steel wire rod, drawn to spec diameters.

- Methods: cold heading, shank forming, diamond point, trimming; HDG or EG per need.

- Testing: dimensional checks per ASTM F1667; bend test 90° without fracture; zinc mass per ASTM A153 (HDG) or ASTM B633/A641 (EG/galv wire); salt spray (ASTM B117) 72–120 h for EG baseline.

- Service life: interior dry ≈ 50+ years; exterior EG ≈ 2–5 years; HDG ≈ 15+ years; coastal or ACQ treated lumber requires HDG/SS for best results.

- Industries: residential framing, pallets/crates, site temp works, set-building.

Applications, advantages, and a small digression

Framing studs and plates, ledger attachments (check code!), subfloor nailing, crate builds—discount 16 d common nails win when they drive straight, resist pull-out, and don’t shear under load. Actual field data we’ve seen shows pull-out values around 130–160 lb in SPF for smooth shank, higher for ring shank, assuming proper embedment.

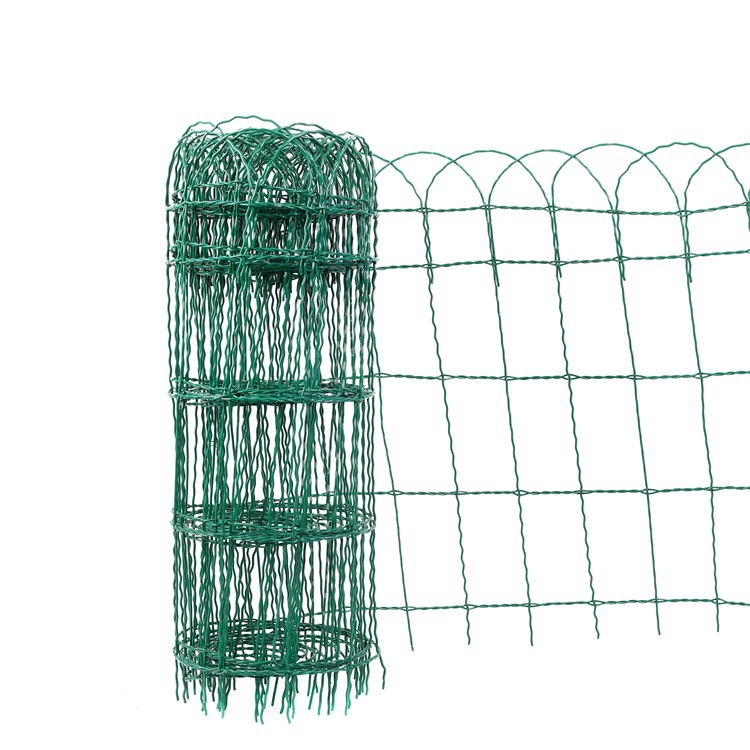

Side note: garden crews we talk to often bundle orders—nails for forms plus PVC-coated border fencing for clean edges. One supplier we visited in Shijiazhuang (Room D808, ZhuoDa Commercial Building, Huai'an West Road, Hebei, China) also ships PVC-coated border green garden wire mesh fence—handy to know if you’re consolidating freight.

Vendor comparison (indicative)

| Vendor | Certifications | Typical Price/Box | MOQ | Lead Time | QC Notes |

|---|---|---|---|---|---|

| Five Star Metals (Shijiazhuang, CN) | ISO 9001 (supplier-level) | Value-tier (varies) | Pallet | 2–4 weeks | Mill test reports, customization |

| Regional Distributor | Vendor-qualified | Mid-range | 1 box | In stock | Tight tolerances, easy returns |

| Online Marketplace Sellers | Mixed | Lowest promos | Case | 3–10 days | Check reviews, coating claims |

Customization and field feedback

Custom head stamps, HDG class upgrades, retail cartons with UPC, collated equivalents for 21° nailers—these are on the menu. Many customers say discount 16 d common nails with better zinc consistency show fewer rust bleeds in fascia repairs after two seasons, which tracks with our salt-spray notes.

Mini case study

A midwest framing crew switched to pallet-ordered discount 16 d common nails (HDG) for ACQ sill plates. Result: ~8% material savings over a quarter, zero returned boxes, and—surprisingly—cleaner countersinks due to tighter diameter control (their words, not mine).

Standards and references

- ASTM F1667 – Standard Specification for Driven Fasteners: Nails, Spikes, and Staples.

- ASTM A153/A153M – Zinc Coating (Hot-Dip) on Iron and Steel Hardware; ASTM B117 – Salt Spray.

- ICC-ES AC233/IRC/IBC fastener guidance for treated wood; ISO 9001 quality management (vendor-level).

-

Discount 16 d Common Nails - Bulk, Durable, Fast Shipping

NewsNov.17,2025

-

Finish Nails - Durable, Rust-Resistant, Clean Countersink

NewsNov.17,2025

-

Barbed Wire: Galvanized, High-Tensile Security Fencing

NewsNov.17,2025

-

Discount 16 d Common Nails – Bulk, Durable, OEM Options

NewsNov.17,2025

-

Welded Steel Tube Temporary Fence – Galvanized, Durable

NewsNov.04,2025

-

Barbed Wire – High-Tensile, Galvanized, Bulk & Fast Shipping

NewsNov.04,2025