mesh chicken wire manufacturer

Understanding the Mesh Chicken Wire Manufacturing Process

When it comes to agriculture and poultry farming, chicken wire has become an essential material. Not only does it keep chickens secure, but it also allows for proper ventilation and visibility. If you’re searching for a reliable mesh chicken wire manufacturer, it's essential to understand the manufacturing process, the materials involved, and the various applications of chicken wire in farming and beyond.

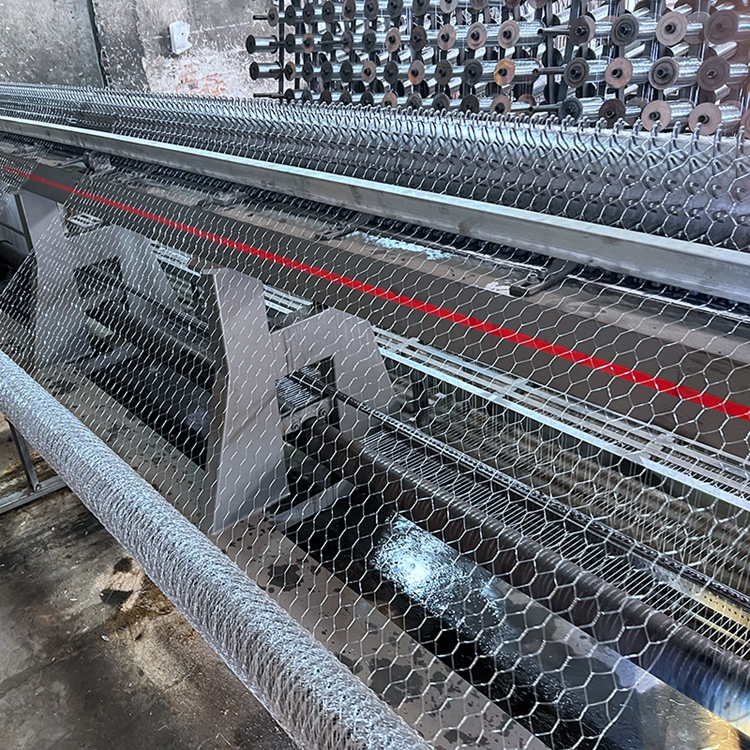

The Manufacturing Process

The production of mesh chicken wire involves several key steps, starting from raw material sourcing to the final product.

1. Raw Materials High-quality steel wire is typically the primary raw material used in the manufacture of chicken wire. Some manufacturers also opt for galvanized wire, which is coated with zinc to prevent rusting and corrosion, extending the life of the wire. For those seeking a more durable product, stainless steel options are available, though they can be more expensive.

2. Drawing and Annealing The first step in shaping the chicken wire is wire drawing, where large steel rods are drawn through progressively smaller dies to create thinner wires. Following this, annealing involves heating the wire to high temperatures, which improves its flexibility and strength while reducing brittleness.

3. Fabrication Once the wire has been drawn and annealed, it is then cut to the desired length. The wires are arranged in a mesh pattern through a weaving process. This creates the typical hexagonal holes that are characteristic of chicken wire. The mesh can come in various sizes, depending on the intended use.

4. Galvanizing To enhance durability and resistance to rust, woven chicken wire is often galvanized. This can be done through a hot-dip or electro-galvanizing process. In the hot-dip method, the wire is submerged in molten zinc, providing a thick coating for maximum protection. The electro-galvanizing process applies a thinner layer of zinc but offers a neat finish.

5. Cutting and Packaging After the galvanization process, the mesh is cut into specified rolls or sheets, depending on market demand. The final product is then rolled up and packaged, ready for distribution to retailers or directly to customers.

Applications of Chicken Wire

Mesh chicken wire is versatile and serves multiple purposes

mesh chicken wire manufacturer

- Poultry Enclosures The primary use of chicken wire is to create secure enclosures for chickens, allowing them to roam freely while keeping predatory animals at bay.

- Garden Fencing Chicken wire is also used in gardens to keep rabbits and other small animals from eating plants and vegetables

. Its transparent nature allows sunlight and air to reach the plants.- Craft Projects In the DIY community, chicken wire is popular for creative projects, including decorative items, photo frames, and even home accents.

- Livestock Beyond chickens, this mesh is commonly employed to enclose other types of livestock and animals, providing a safe environment while ensuring visibility from outside.

Choosing the Right Manufacturer

When selecting a mesh chicken wire manufacturer, several factors should be considered

- Quality of Material Look for manufacturers that use high-quality raw materials, preferably those that provide galvanized options for increased durability and resistance to environmental wear.

- Production Standards Check if the manufacturer adheres to industry standards and whether they have certifications that assure quality control during the production process.

- Customization Options Different projects may require different types of wire mesh. A good manufacturer should provide customization options, whether in terms of gauge, length, or mesh size.

- Customer Service Opt for manufacturers known for excellent customer service. They should be willing to provide information, support, and potentially guides on the best types of chicken wire for your needs.

In conclusion, mesh chicken wire is a crucial component in poultry farming and various applications, and understanding the manufacturing process and available options can help you make an informed choice. Selecting a reliable manufacturer ensures that your chicken wire not only protects your poultry but also serves its purpose effectively and lasts for years to come.

-

Iron Nails Evolving Sentience in Landfill Ecosystems

NewsAug.22,2025

-

Black Iron Nails: Raw Power, Five-Star Forged

NewsAug.22,2025

-

Wire Mesh: Dingzhou's Industrial Language

NewsAug.22,2025

-

Reflective PVC Coated Wire Mesh Highway Safety

NewsAug.22,2025

-

High Carbon Steel Wire Suspended Desalination Nets

NewsAug.22,2025

-

Steel Wire Sparks: Five-Star's Origin Story

NewsAug.22,2025