Manufacturer of Loose Pallets and Nails for Enhanced Storage Solutions

Understanding Loose Pallets and Nail Manufacturing

In the world of logistics and shipping, the importance of reliable packaging solutions cannot be overstated. Among various packaging options available, pallets play a crucial role in ensuring that goods are transported safely and efficiently. Loose pallets, in particular, have gained traction in industries where flexibility and cost-effectiveness are prioritized. One critical component in the manufacturing of these pallets is the nails used to hold them together, making the role of nail manufacturers essential in this ecosystem.

What Are Loose Pallets?

Loose pallets are essentially flat transport structures that can be easily transported and stored without being secured in a fixed position. Unlike traditional pallets, which are often tied into stacks, loose pallets allow for greater flexibility in handling goods, especially in scenarios where frequent loading and unloading are required. They are often used in warehouses, shipping docks, and distribution centers. The advantage of loose pallets lies in their ability to adapt to various logistics needs, making them ideal for companies dealing with fluctuating inventory levels or diverse types of goods.

The Role of Nails in Pallet Manufacturing

Nails are an integral part of the pallet manufacturing process. They provide the structural integrity needed for pallets to support heavy loads while ensuring durability over time. The right type of nails can significantly affect the quality of the pallets, making it essential for manufacturers to source nails that meet specific standards. This includes factors such as tensile strength, corrosion resistance, and overall security when handling products.

Nail manufacturers play a pivotal role in this regard. They produce a wide variety of nail types designed for different applications, including galvanized nails for moisture resistance and coated nails for added durability. The quality of nails directly impacts not just the pallets, but also the entire logistics chain, affecting everything from shipping efficiency to product safety.

Challenges Faced by Nail Manufacturers

loose pallets nail manufacturer

Despite the vital role they play, nail manufacturers face several challenges that can affect supply chains. The fluctuating costs of raw materials, such as steel, can drive up production costs, leading to increased prices for pallet manufacturers. Additionally, stringent regulations surrounding material safety and environmental concerns are pushing nail manufacturers to innovate and produce more sustainable solutions.

Moreover, the competitive landscape of the nail manufacturing industry necessitates continual improvement and adaptation. Companies that can leverage new manufacturing technologies or materials stand a better chance of meeting the diverse needs of pallet producers and, ultimately, end-users.

The Future of Loose Pallets and Nail Manufacturing

As e-commerce continues to grow and consumer expectations evolve, the demand for efficient logistics solutions will likely increase. This will place further emphasis on the need for high-quality loose pallets and the nails that hold them together. Innovation in both pallet designs and nail manufacturing processes will be crucial in meeting these needs.

One area of focus for future advancements will likely be sustainability. The industry is leaning towards eco-friendly materials and production processes, aiming to reduce waste and lower carbon footprints. Industries are increasingly exploring alternative materials for pallets, such as recycled plastics and composite materials, which may also influence the types of nails required.

Conclusion

The interplay between loose pallets and nail manufacturing is a testament to the complexities of the modern logistics and shipping industry. While loose pallets offer flexibility and efficiency, the nails that secure them provide the necessary strength and durability. As market demands evolve, both pallet manufacturers and nail producers must stay ahead of the curve, ensuring their products not only meet current needs but also anticipate future challenges. By focusing on quality, sustainability, and innovation, these industries can continue to thrive in a competitive market while delivering exceptional value to their clients.

-

Iron Nails Evolving Sentience in Landfill Ecosystems

NewsAug.22,2025

-

Black Iron Nails: Raw Power, Five-Star Forged

NewsAug.22,2025

-

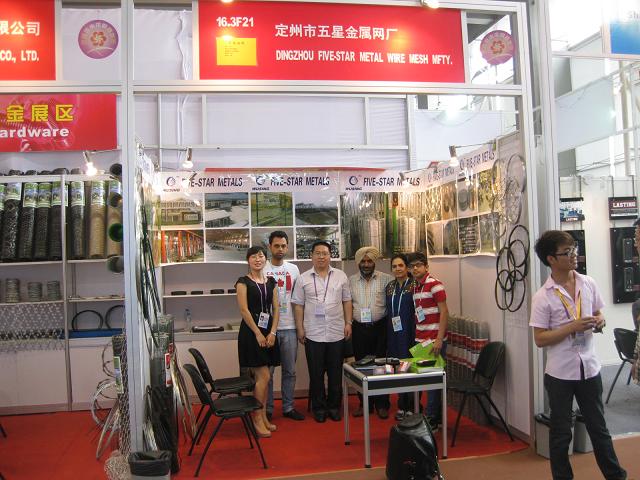

Wire Mesh: Dingzhou's Industrial Language

NewsAug.22,2025

-

Reflective PVC Coated Wire Mesh Highway Safety

NewsAug.22,2025

-

High Carbon Steel Wire Suspended Desalination Nets

NewsAug.22,2025

-

Steel Wire Sparks: Five-Star's Origin Story

NewsAug.22,2025