Durable Woven Mesh Temporary Fence | Easy Install Site Security

Introduction to Advanced Temporary Fencing Solutions

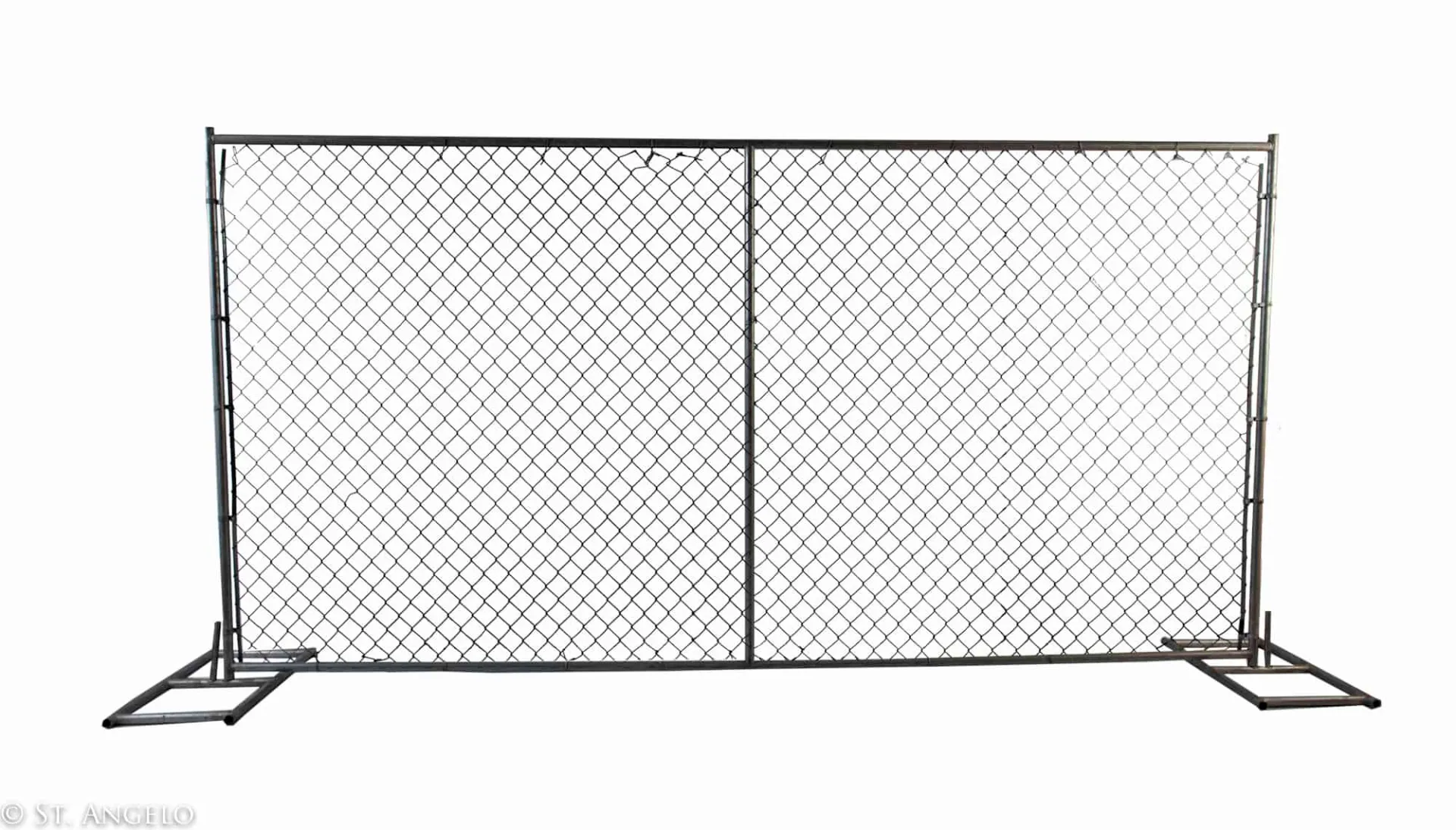

In dynamic operational environments such as construction sites, event venues, and industrial facilities, the need for robust, reliable, and rapidly deployable perimeter security is paramount. The Woven Mesh Temporary Fence system represents a critical advancement in this domain, offering a superior alternative to conventional fencing. Engineered for rapid deployment and maximum security, these fences are designed to withstand challenging conditions while providing a clear delineation of boundaries. This comprehensive overview will delve into the technical specifications, manufacturing processes, application scenarios, and strategic advantages of modern woven mesh temporary fencing, providing B2B decision-makers with the insights necessary for informed procurement.

Industry Trends and Market Dynamics

The global temporary fencing market is experiencing significant growth, driven by escalating investments in infrastructure, the proliferation of large-scale public events, and heightened security concerns across various sectors. According to recent market analysis, the temporary fencing market is projected to reach USD 7.8 billion by 2028, growing at a CAGR of 6.2%. Key trends include the demand for more durable and reusable fencing solutions, enhanced anti-climb features, and modular designs that facilitate rapid installation and dismantling. There's a noticeable shift towards materials offering superior corrosion resistance and longevity, reducing the total cost of ownership (TCO) for project managers. Furthermore, environmental regulations are pushing for materials with lower ecological impact and higher recyclability, making robust metallic solutions like the Woven Mesh Temporary Fence increasingly attractive.

Technological advancements are also influencing design, with lightweight yet high-strength alloys and advanced coating technologies extending service life and performance. The integration of smart perimeter security systems, though nascent, is also on the horizon, promising further enhancements to the utility of temporary fencing.

Manufacturing Process: Precision Engineering for Durability

The production of a high-quality Woven Mesh Temporary Fence involves a meticulous multi-stage manufacturing process, ensuring optimal structural integrity and longevity. This process typically adheres to stringent international standards such as ISO 9001 for quality management and ASTM standards for material properties.

Process Flow:

- Material Selection: High-grade carbon steel or galvanized steel wire (typically Q195 or Q235, conforming to ASTM A641) is selected for its tensile strength and ductility. For enhanced corrosion resistance, zinc-aluminum alloy coated wire or stainless steel variants (e.g., 304, 316) may be specified.

- Wire Drawing and Straightening: The raw steel coils undergo a cold drawing process to achieve the desired wire gauge (e.g., 2.5mm to 5.0mm diameter). Advanced CNC wire straightening machines ensure uniformity, which is critical for precise weaving.

- Mesh Weaving: Utilizing automated weaving looms, the straightened wires are interlocked to form a robust mesh pattern (typically square or rectangular apertures, e.g., 50x50mm, 75x150mm). This process, unlike welding, creates a flexible yet incredibly strong structure, distributing stress evenly across the panel.

- Panel Fabrication: The woven mesh is cut to specified panel dimensions. Steel tubing (e.g., 32mm OD, 1.5mm wall thickness) is cut and formed to create the outer frame. These frame components are then precision-welded to enclose and support the woven mesh panel. All welding processes adhere to ISO 3834 standards.

- Surface Treatment:

- Hot-Dip Galvanization: Panels are immersed in molten zinc at approximately 450°C, creating a metallurgical bond that provides superior corrosion protection (typically 42-60 µm coating thickness, conforming to ISO 1461/ASTM A123). This ensures extended service life even in harsh outdoor environments.

- Powder Coating: For enhanced aesthetics and additional corrosion resistance, an electrostatic powder coating (e.g., polyester or epoxy-polyester) is applied and then oven-cured. This provides a durable, chip-resistant finish available in various RAL colors.

- Quality Control & Testing: Each batch undergoes rigorous testing, including:

- Material Composition Analysis: Spectrographic analysis of raw materials.

- Tensile Strength Testing: Performed on wire and mesh to confirm mechanical properties.

- Coating Thickness Measurement: Using magnetic induction or eddy current methods.

- Adhesion Testing: Cross-hatch tests for powder coatings.

- Salt Spray Testing: Accelerated corrosion testing (e.g., ASTM B117) to evaluate long-term durability.

- Assembly & Packaging: Final panels are assembled with appropriate accessories (bases, clamps) and securely packaged for transport, preventing damage.

This rigorous process ensures a service life typically exceeding 10-15 years for galvanized and powder-coated systems, depending on environmental conditions and maintenance.

Technical Specifications and Performance Parameters

Understanding the precise technical specifications of a Woven Mesh Temporary Fence is crucial for project planning and compliance. The following table outlines typical parameters for high-performance systems.

Woven Mesh Temporary Fence: Key Specifications

| Parameter | Standard Specification | Typical Range/Value |

|---|---|---|

| Panel Height | ISO 13900 | 1.8 m, 2.1 m, 2.4 m |

| Panel Width | ISO 13900 | 2.4 m, 2.9 m, 3.5 m |

| Wire Diameter (Mesh) | ASTM A641 | 2.5 mm – 5.0 mm |

| Mesh Aperture | ASTM A641 | 50x50 mm, 75x150 mm, 60x150 mm |

| Frame Pipe Diameter | ASTM A53 | 32 mm OD, 38 mm OD, 42 mm OD |

| Frame Pipe Wall Thickness | ASTM A53 | 1.5 mm – 2.5 mm |

| Surface Treatment | ISO 1461, ASTM A123 | Hot-dip galvanized (42-60 µm), Powder coated |

| Base Type | Manufacturer Specific | Plastic (HDPE) with concrete, Steel, Rubber |

| Wind Load Resistance | AS 4687-2007 (Australia) | Up to 90 km/h (with proper bracing) |

| Service Life | Based on material/coating | 10-15+ years for galvanized/powder coated |

Technical Advantages of Woven Mesh Systems

The inherent design and material properties of a Woven Mesh Temporary Fence provide distinct advantages over alternative temporary barrier systems. These advantages translate directly into operational efficiency, enhanced safety, and reduced lifecycle costs for industrial and commercial applications.

- Superior Durability and Impact Resistance: Unlike welded mesh which can fail catastrophically at a single weld point, woven mesh distributes impact loads across multiple interlocked wires. This offers significantly higher resistance to localized stress, making it ideal for high-traffic or high-impact environments.

- Exceptional Corrosion Resistance: Primarily due to the hot-dip galvanization process (ISO 1461, ASTM A123), these fences exhibit outstanding resistance to rust and environmental degradation. This is crucial for applications in coastal regions, high-humidity zones, or areas exposed to industrial chemicals, greatly extending their operational lifespan without frequent maintenance.

- Enhanced Security Features: The tightly woven pattern and smaller apertures, often combined with anti-climb top edges, deter unauthorized access more effectively than larger mesh alternatives. This is vital for securing sensitive areas and controlling pedestrian flow.

- Modular and Reusable Design: Designed for rapid assembly and disassembly, these panels are easily transported, stored, and re-deployed across multiple projects. This reusability leads to significant cost savings and reduces waste, aligning with sustainable operational practices.

- Versatility and Adaptability: Compatible with various base types (concrete blocks, steel feet) and attachment systems (couplers, clamps), woven mesh fences can be configured for diverse terrains and security requirements. They are easily adapted to uneven ground or angular layouts.

- Cost-Effectiveness over Lifecycle: While initial investment might be comparable to other systems, the superior durability, corrosion resistance, and reusability of woven mesh fences drastically reduce long-term maintenance, replacement, and disposal costs, offering a compelling return on investment (ROI).

- Visibility and Aesthetic Integration: The open mesh design allows for good visibility into and out of the enclosed area, which is important for site supervision and safety. When powder-coated, they can also blend more harmoniously with the surrounding environment, a factor for public-facing events.

Application Scenarios and Target Industries

The robust design and adaptability of the Woven Mesh Temporary Fence make it an indispensable asset across a multitude of industries requiring temporary perimeter control and security.

- Construction & Infrastructure Projects: Essential for delineating construction zones, protecting workers and the public from hazards, and securing valuable equipment and materials on site. Used in highway construction, commercial building developments, and utility installation.

- Petrochemical & Energy Sector: For temporary exclusion zones around hazardous materials, maintenance work areas, or new installations in refineries, power plants, and chemical processing facilities. The corrosion resistance is particularly vital in these environments.

- Metallurgy & Mining: Securing open-pit mines, processing plants, and material stockpiles. Robustness against heavy machinery impacts and corrosive atmospheres is a key benefit.

- Water Supply & Drainage Utilities: Protecting access to reservoirs, pumping stations, pipeline construction sites, and wastewater treatment facilities, ensuring public safety and operational security.

- Public Events & Crowd Control: Managing crowd flow, securing VIP areas, setting up queues, and delineating boundaries for festivals, concerts, sporting events, and exhibitions. Rapid deployment and high visibility are critical here.

- Emergency Response & Disaster Relief: Quickly establishing secure perimeters around disaster zones, temporary shelters, or mobile command centers. Their rapid deployment and stability are paramount in urgent situations.

- Security & Border Control: For temporary checkpoints, perimeter enhancements, or rapidly deployed security zones in high-risk areas.

Vendor Comparison and Selection Criteria

Selecting the right supplier for a Woven Mesh Temporary Fence requires a thorough evaluation beyond mere unit cost. B2B decision-makers should prioritize vendors demonstrating adherence to quality standards, robust manufacturing capabilities, and comprehensive customer support.

Key Vendor Evaluation Criteria:

- Certifications and Compliance: Verify adherence to international quality standards (e.g., ISO 9001), material specifications (e.g., ASTM, EN), and environmental regulations.

- Manufacturing Capabilities: Assess production capacity, the use of advanced machinery (e.g., CNC weaving), and quality control protocols throughout the process.

- Material Purity and Treatment: Inquire about the grade of steel, zinc coating thickness for galvanization (measured in g/m² or µm), and powder coating specifications.

- Customization Options: Evaluate the ability to provide tailored panel dimensions, mesh apertures, frame specifications, and color options to meet unique project requirements.

- Logistics and Fulfillment: Consider lead times, shipping efficiency, and packaging standards to prevent transit damage.

- After-Sales Support & Warranty: A clear warranty policy, availability of spare parts, and responsive technical support are indicative of a reliable partner.

- Industry Experience and References: Look for vendors with a proven track record in your specific industry and request client testimonials or case studies.

Comparison of Fencing Types (Illustrative)

| Feature | Woven Mesh Temporary Fence | Welded Mesh Temporary Fence | Chain Link Temporary Fence |

|---|---|---|---|

| Durability/Impact Resistance | High (woven structure distributes stress) | Medium (weld points can be weak) | Medium-High (flexible, but can unravel) |

| Anti-Climb Capability | High (small, tight apertures) | Medium (larger apertures can offer footholds) | Low-Medium (easy to grip/climb) |

| Corrosion Resistance | Excellent (Hot-dip galvanized, Powder-coated) | Good (Hot-dip galvanized, Powder-coated) | Good (Galvanized, sometimes PVC coated) |

| Reusability | Excellent (Long service life, robust panels) | Good (Less robust than woven mesh) | Good (Can be tangled or damaged easily) |

| Cost (Lifecycle) | Medium-Low (High initial, very low maintenance/replacement) | Medium | Low-Medium (Lower initial, higher long-term maintenance) |

Customized Solutions

Recognizing that every project has unique demands, leading manufacturers of Woven Mesh Temporary Fence offer extensive customization options. This ensures that the fencing system perfectly aligns with specific operational, security, and aesthetic requirements.

- Dimensions: Custom heights and widths for panels and gates to accommodate unusual site layouts or specific security clearances.

- Mesh Specifications: Variable wire diameters and mesh aperture sizes (e.g., smaller apertures for enhanced anti-climb, larger for improved visibility).

- Frame Design: Different pipe diameters and wall thicknesses for increased rigidity or wind load resistance. Integration of razor wire or barbed wire extensions.

- Surface Finishes: Beyond standard galvanization, custom powder coating colors (RAL palette) for corporate branding or specific environmental camouflage. Specialized anti-corrosion coatings for extreme conditions.

- Access Solutions: Tailored pedestrian gates, vehicle gates (single or double swing), and turnstiles, all designed to integrate seamlessly with the temporary fence line.

- Ancillary Components: Bespoke heavy-duty bases, anti-lift devices, shade cloth attachments, and signage integration points.

Our engineering team collaborates closely with clients from conceptualization to deployment, providing CAD drawings and structural analysis to ensure that customized solutions meet or exceed performance expectations and regulatory compliance.

Application Case Studies

Case Study 1: Major Urban Infrastructure Project

Client: Tier-1 Construction Contractor for a Metropolitan Light Rail Expansion.

Challenge: Secure multiple active construction zones along a busy urban corridor, requiring high visibility, robust perimeter security, and rapid re-configuration as phases progressed. Public safety and prevention of unauthorized access were paramount.

Solution: Deployment of 3,500 linear meters of Woven Mesh Temporary Fence (2.1m height, 38mm OD frame, hot-dip galvanized and green powder-coated). Panels were equipped with concrete-filled HDPE bases for stability and anti-climb mesh apertures (50x50mm). Integrated pedestrian and vehicle gates ensured controlled access.

Outcome: The system provided effective site security for over 18 months, enduring varying weather conditions without degradation. Its modular nature allowed for weekly reconfigurations with minimal labor, reducing project downtime by an estimated 15%. Public feedback regarding safety and site aesthetics was consistently positive.

Case Study 2: International Sporting Event Perimeter

Client: Event Management Committee for a Global Cycling Championship.

Challenge: Establish a secure, attractive, and rapidly deployable perimeter around start/finish lines, spectator zones, and VIP areas across a 25 km course, accommodating hundreds of thousands of attendees. Aesthetics and branding were crucial.

Solution: Provision of 5,000 linear meters of custom-height (1.5m) Woven Mesh Temporary Fence with a unique branded blue powder coating. Lighter steel bases were used for rapid deployment and easy repositioning. Integrated media banners were seamlessly attached to the fence panels.

Outcome: The fencing system was installed within 72 hours and dismantled within 48 hours post-event. Its stability ensured crowd safety, and the custom branding enhanced the event's professional image. The reusability of the panels for future events provided significant long-term savings.

Frequently Asked Questions (FAQ)

Q: What is the typical lead time for a standard Woven Mesh Temporary Fence order?

A: For standard configurations and quantities (e.g., up to 1,000 linear meters), the typical lead time is 2-3 weeks from order confirmation. Custom orders or larger volumes may require 4-6 weeks, depending on the complexity and current production schedule. We recommend contacting our sales team for precise lead time estimates.

Q: What is the expected service life of your temporary fence systems?

A: Our hot-dip galvanized and powder-coated Woven Mesh Temporary Fence systems are designed for a service life exceeding 10-15 years under typical outdoor conditions, with proper installation and maintenance. This is backed by our material and coating quality certifications.

Q: Do you offer installation services or guidance?

A: While our systems are designed for straightforward installation by competent personnel, we provide comprehensive installation manuals and remote technical support. For large or complex projects, we can also recommend certified installation partners in various regions.

Q: What warranty is provided with the Woven Mesh Temporary Fence?

A: We offer a 5-year limited warranty on manufacturing defects and a 10-year anti-corrosion warranty on our hot-dip galvanized and powder-coated products, subject to standard terms and conditions. Full warranty details are available upon request.

Lead Time, Fulfillment, and Customer Support

Our commitment to efficiency extends to logistics and customer service. We understand that timely delivery is critical for project success.

- Lead Time: As detailed in the FAQ, standard orders are fulfilled within 2-3 weeks. Expedited options may be available depending on inventory and production capacity.

- Fulfillment: Our advanced logistics network ensures efficient and secure delivery to your project site, globally. Each shipment undergoes a final quality check and is meticulously packaged to prevent damage during transit. We work with trusted freight partners to provide reliable delivery schedules.

- Warranty Commitments: Our 5-year manufacturing defect warranty and 10-year anti-corrosion warranty underscore our confidence in product quality. We are dedicated to rectifying any issues promptly and professionally.

- Customer Support: Our dedicated B2B support team is available from [Your Business Hours, e.g., 8:00 AM - 5:00 PM EST] to assist with technical queries, order tracking, and after-sales service. We offer multi-channel support including phone, email, and a dedicated online portal for client accounts.

Conclusion

The Woven Mesh Temporary Fence stands as a testament to advanced engineering in perimeter security. Its superior durability, exceptional corrosion resistance, and versatile application across critical industries make it the preferred choice for discerning B2B clients. By combining meticulous manufacturing, adherence to global standards, and comprehensive customer support, these fencing systems offer a cost-effective, reliable, and sustainable solution for temporary demarcation and security needs. Investing in high-quality woven mesh fencing ensures not only immediate operational efficiency but also long-term value and peace of mind.

References

- ASTM International. (Various Standards: A641, A123, B117, A53).

- International Organization for Standardization (ISO). (Various Standards: 9001, 1461, 3834).

- MarketsandMarkets. (2023). Temporary Fencing Market - Global Forecast to 2028.

- Standards Australia. (2007). AS 4687-2007: Temporary fencing and hoarding.

-

Discount 16 d Common Nails - Bulk, Durable, Fast Shipping

NewsNov.17,2025

-

Finish Nails - Durable, Rust-Resistant, Clean Countersink

NewsNov.17,2025

-

Barbed Wire: Galvanized, High-Tensile Security Fencing

NewsNov.17,2025

-

Discount 16 d Common Nails – Bulk, Durable, OEM Options

NewsNov.17,2025

-

Welded Steel Tube Temporary Fence – Galvanized, Durable

NewsNov.04,2025

-

Barbed Wire – High-Tensile, Galvanized, Bulk & Fast Shipping

NewsNov.04,2025