Discount 16 D Common Nails & Fasteners | Bulk Savings

Introduction to High-Performance Common Nails for Industrial Applications

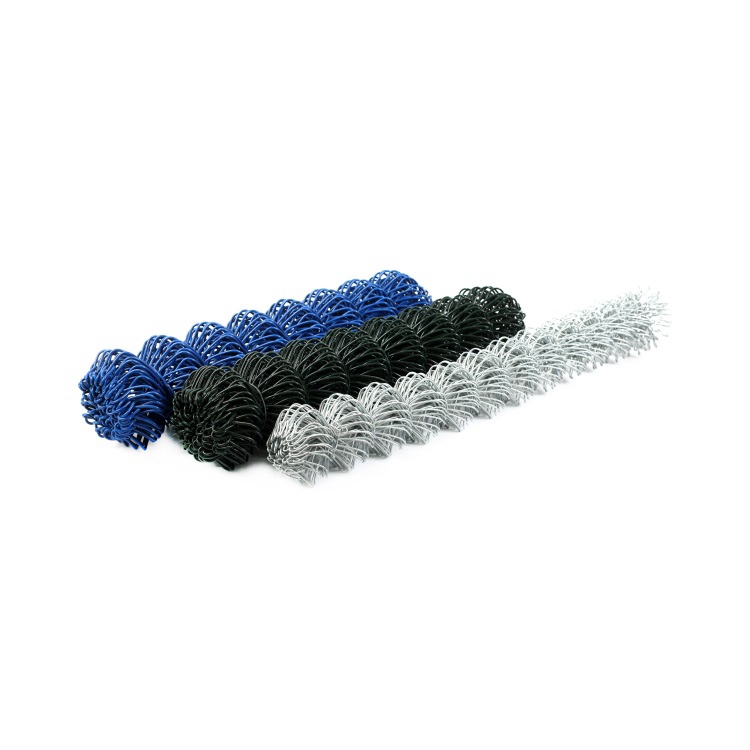

In the demanding landscape of modern construction and industrial fabrication, the reliability of fasteners is paramount. Choosing the right nail impacts not only structural integrity but also project timelines and long-term cost-efficiency. Among the myriad of fastening solutions, common nails, particularly those engineered for robust performance and value, stand out. This detailed overview focuses on the crucial role and advanced specifications of discount 16 d common nails, a staple in heavy-duty applications. Designed for superior holding power and durability, these nails are indispensable in projects ranging from framing and subflooring to formwork and general construction. Our commitment extends to providing comprehensive fastening solutions, including complementary products like discount 16.5g black annealed tie wire price, discount steel wire mesh, and discount y post fence black, all engineered to meet stringent industry standards and optimize procurement for B2B clients.

Understanding the technical nuances, market trends, and application versatility of such critical components is essential for procurement managers and project engineers. We delve into the manufacturing excellence, material science, and strategic advantages that position these fasteners as a cornerstone for reliable construction, ensuring that quality is never compromised, even with competitive pricing structures.

Industry Trends and Market Dynamics in Fastener Technology

The global construction and manufacturing industries are continually evolving, driven by advancements in material science, automation, and a strong emphasis on sustainability. Current trends in fastener technology reflect a demand for enhanced performance, corrosion resistance, and simplified installation. There is a noticeable shift towards fasteners that offer superior load-bearing capabilities and extended service life, reducing maintenance costs and improving structural longevity. The market for common nails, particularly for high-volume applications, is experiencing robust growth, fueled by rapid urbanization and infrastructure development worldwide. The strategic sourcing of high-quality yet cost-effective solutions like discount 16 d common nails is becoming a critical competitive advantage for businesses.

Furthermore, the integration of digital tools for inventory management and supply chain optimization is streamlining the procurement process, allowing for more efficient access to essential components. Innovations in protective coatings, such as advanced galvanization techniques, are extending the utility of steel fasteners in harsh environments, from coastal construction to industrial processing facilities. This focus on durability and performance, coupled with the economic benefits of bulk purchasing, defines the current trajectory for industrial fasteners.

Fig. 1: Modern manufacturing processes enhance the durability and consistency of common nails.

Technical Specifications of 16 d Common Nails

The designation "16 d" refers to the "penny" system, historically indicating the price per hundred nails, but now signifying specific dimensions. A 16 d common nail typically has a length of 3 ½ inches (88.9 mm) and a standard shank diameter of 0.162 inches (4.11 mm) – approximately 8 gauge. These nails are characterized by a thick, heavy shank, a large, flat head, and a diamond point. This robust construction is engineered to provide maximum holding power in wood and other materials.

Our discount 16 d common nails are manufactured from high-quality carbon steel, ensuring superior tensile and shear strength. Depending on the application, they are available in a bright (untreated) finish for interior use or with various protective coatings such as hot-dip galvanization for enhanced corrosion resistance in outdoor or humid environments. Hot-dip galvanization, a process where steel is immersed in molten zinc, creates a metallurgical bond that provides a resilient barrier against rust and abrasion, significantly extending service life.

Key Technical Parameters:

| Parameter | Specification for 16 d Common Nails | Industry Standard Reference |

|---|---|---|

| Length | 3.5 inches (88.9 mm) | ASTM F1667 |

| Shank Diameter | 0.162 inches (4.11 mm) | ASTM F1667 (approx. 8 gauge) |

| Head Diameter | Approx. 0.344 inches (8.74 mm) | Manufacturer Specific / General Practice |

| Material | High-Carbon Steel (SAE 1008-1018) | AISI/SAE Standards |

| Finish Options | Bright, Hot-Dip Galvanized, Electro-Galvanized | ASTM A153 (HDG), ASTM B695 (EG) |

| Tensile Strength | 55,000 - 80,000 PSI (dependent on material/heat treatment) | ASTM F1667 |

| Shear Strength | 120-150 lbs (typical for wood applications) | Nail manufacturer's internal testing |

These specifications ensure that the 16 d common nail provides robust structural connections, essential for applications requiring significant withdrawal resistance and shear load capacity. Our adherence to international standards like ISO 9001 for quality management systems further guarantees the consistency and reliability of our products.

Manufacturing Process Flow for Discount 16 d Common Nails

The production of high-quality discount 16 d common nails involves a meticulously controlled manufacturing process, leveraging precision machinery and stringent quality checks at every stage. This ensures that the final product consistently meets or exceeds industrial standards for strength, durability, and dimensional accuracy.

Process Steps:

- Wire Rod Procurement & Preparation: High-carbon steel wire rod, conforming to AISI/SAE standards (e.g., 1008-1018), is sourced. The rod undergoes descaling and drawing processes to achieve the precise diameter required for 16 d nails. This step is critical for controlling the nail's ultimate strength and ductility.

-

Nail Forming (Cold Forging): The drawn wire is fed into high-speed nail-making machines. These machines perform three primary operations simultaneously:

- Heading: One end of the wire is struck by a header die to form the flat head.

- Pointing: The other end is cut and shaped into a diamond point by pointing dies.

- Shank Formation: The desired length of the nail is cut, and the shank is straightened. Some processes might include minor knurling for enhanced withdrawal resistance.

- Tumbling and Cleaning: Newly formed nails are tumbled in large drums to remove burrs, metal shavings, and any residual oil, ensuring a smooth finish and preventing corrosion during storage before coating.

-

Surface Treatment/Coating: Depending on client specifications and intended application:

- Bright Finish: Nails are left as-is after cleaning for interior applications where corrosion is not a concern.

- Hot-Dip Galvanization: Nails are immersed in molten zinc at high temperatures. This creates a thick, highly durable zinc coating that metallurgically bonds to the steel, offering superior corrosion resistance for outdoor and harsh environments. This process adheres to ASTM A153 standards.

- Electro-Galvanization: A thinner zinc coating is applied electrolytically, providing moderate corrosion protection, often preferred for aesthetic reasons or less aggressive environments. This adheres to ASTM B695.

-

Quality Control & Testing: Throughout the process, and especially after coating, nails undergo rigorous quality checks. These include:

- Dimensional inspection (length, shank diameter, head size).

- Withdrawal strength testing (ASTM F1667).

- Shear strength testing.

- Coating thickness and adhesion testing (e.g., for galvanized nails).

- Material composition analysis.

- Packaging: Finished and inspected nails are sorted, counted, and packaged in bulk cartons, plastic pails, or specific quantities as per client requirements, ready for shipment. Proper packaging protects the nails during transit and storage.

This meticulous process guarantees that each discount 16 d common nail delivers optimal performance, ensuring energy saving through efficient installation and remarkable corrosion resistance for enhanced service life in diverse target industries such as general construction, petrochemical, and metallurgy.

Application Scenarios and Target Industries

The robust design and superior holding power of discount 16 d common nails make them ideal for a wide array of heavy-duty fastening applications across various industrial sectors. Their versatility and reliability are unmatched in situations requiring strong, permanent connections.

- Residential and Commercial Framing: Essential for constructing wall frames, floor joists, and roof trusses, where their larger diameter provides excellent shear resistance and prevents pull-out.

- Heavy Timber Construction: Used in log homes, large beam connections, and other timber structures where significant structural integrity is required.

- Formwork and Concrete Pouring: Vital for assembling temporary wooden forms for concrete pouring, their strength ensures the formwork withstands the immense pressure of wet concrete.

- Subflooring and Sheathing: Securing plywood or OSB subflooring to joists and attaching wall or roof sheathing, providing a stable and durable base.

- Pallet Manufacturing and Crating: Widely employed in the fabrication of wooden pallets and shipping crates, where robust connections are critical for transporting heavy goods. (This ties in with `oem bostitch pallet nail` conceptually).

- Fencing and Outdoor Structures: Galvanized versions are perfect for constructing wooden fences, decks, sheds, and other outdoor structures that require resistance to weathering and corrosion.

- General Repairs and Renovation: An all-purpose fastener for various repair and renovation tasks requiring substantial fastening power.

Target industries include general construction, residential and commercial building, prefabrication, logistics and packaging, and even specialized applications within the petrochemical and metallurgy sectors for temporary structural supports or wooden components within their facilities. The emphasis on robust construction and optional corrosion resistance makes these nails indispensable for long-term project success.

Technical Advantages and Performance Metrics

The technical advantages of discount 16 d common nails stem from their inherent design and material properties, positioning them as a superior choice for critical fastening tasks.

- Exceptional Holding Power: The thick shank and large head of a 16 d common nail provide a significantly larger surface area for friction and head pull-through resistance compared to smaller nails or brads. This translates to superior withdrawal resistance, crucial for structural stability in framing and sheathing.

- High Shear Strength: Due to their substantial diameter, these nails exhibit excellent shear strength, capable of withstanding considerable lateral forces. This is paramount in applications like timber framing where joints are subjected to racking and dynamic loads.

- Durability and Longevity: Manufactured from high-grade carbon steel, our nails are built to last. When hot-dip galvanized, they offer exceptional corrosion resistance, extending the service life of structures in outdoor, humid, or even marine environments by preventing rust and material degradation. This significantly reduces maintenance and replacement costs over the lifespan of a project.

- Cost-Effectiveness: While offering premium performance, our discount 16 d common nails provide an outstanding balance of quality and cost. Bulk purchasing options further enhance their economic viability for large-scale projects, delivering significant savings without compromising on structural integrity.

- Versatility: Suitable for both manual hammering and pneumatic nailing systems, they adapt to various construction methodologies, enhancing efficiency on site.

Fig. 2: The robust design of 16 d common nails ensures superior holding power and durability in various construction materials.

Performance Comparison: 16 d Common vs. Finish Nails

Understanding the distinction between nail types is crucial for optimal material specification. The table below highlights key differences demonstrating the inherent advantages of common nails for structural applications.

| Feature | 16 d Common Nails | Finish Nails (e.g., 16 gauge) |

|---|---|---|

| Shank Diameter | Thick (0.162 in / 8 gauge) | Thin (0.0625 in / 16 gauge) |

| Head Type | Large, flat | Small, cone/brad |

| Holding Power | Excellent (high withdrawal & shear) | Good (primarily withdrawal) |

| Primary Application | Structural framing, heavy construction | Trim, molding, delicate woodworking |

| Visibility After Installation | High (often driven flush) | Low (can be countersunk and filled) |

Vendor Comparison and Strategic Sourcing for Fasteners

Selecting the right supplier for industrial fasteners like discount 16 d common nails is a strategic decision that goes beyond merely comparing unit prices. A reliable vendor offers a combination of consistent quality, comprehensive service, and logistical efficiency. Key factors for B2B decision-makers and engineers to evaluate include:

- Quality Assurance: Verify adherence to international standards (e.g., ISO, ASTM, ANSI). Request material test reports (MTRs) and certifications for batch traceability and quality consistency.

- Manufacturing Capabilities: Assess the vendor's ability to produce specific quantities, maintain tight tolerances, and apply diverse coatings (e.g., hot-dip galvanization, zinc plating).

- Supply Chain Reliability: Evaluate lead times, order fulfillment rates, and logistical capabilities. A robust supply chain minimizes project delays and inventory holding costs.

- Technical Support and Expertise: A knowledgeable supplier can offer guidance on product selection, application best practices, and troubleshooting, acting as a valuable extension of your technical team.

- Customization Options: The ability to provide customized solutions, such as specific finishes, packaging, or even slightly modified designs, can be a significant advantage for unique project requirements.

- Pricing Structure: While not the sole determinant, a competitive pricing model for bulk orders, coupled with transparent terms, is crucial for budget management.

Our company prioritizes all these aspects, leveraging years of experience and a robust network of partner clients across various industries. We ensure that our fasteners, including specialist products like oem anchor bolt grade 4.6 and oem cap mushroom, meet the highest performance and reliability benchmarks.

Customized Solutions and Bulk Procurement Advantages

Recognizing that every B2B project has unique demands, we specialize in offering customized fastener solutions tailored to specific engineering and procurement needs. Beyond standard bulk orders of discount 16 d common nails, our capabilities extend to OEM/ODM partnerships, allowing for precise control over product specifications.

- Material Grade Selection: For applications requiring specific metallurgical properties, we can source and manufacture nails from specialized steel alloys to enhance characteristics like ductility, hardness, or corrosion resistance.

- Custom Coatings and Finishes: Beyond standard bright or hot-dip galvanized, we can provide alternative coatings, such as polymer-based anti-corrosion layers, or specific colors for identification purposes.

- Unique Dimensions and Geometries: While 16 d is a standard, slight modifications to length, shank diameter, or head type can be accommodated for niche applications, aligning with the principles behind oem square wire welded mesh or oem welded wire mesh fence panels in 12 gauge for specific project demands.

- Specialized Packaging: From custom branding and labeling to specific count requirements or protective packaging for harsh transit conditions, we offer flexible packaging solutions to streamline your on-site logistics and inventory management.

- Comprehensive Project Bundling: We can offer bundled solutions that include not just common nails, but also related products like oem plastic mushroom rebar cap and various types of tie wire, simplifying procurement and ensuring compatibility across all components.

Our deep understanding of B2B client needs, combined with our manufacturing agility, allows us to deliver not just products, but complete fastening strategies. This approach maximizes project efficiency, reduces procurement complexities, and provides a distinct competitive edge for our partners.

Application Case Studies: Proving Reliability in Practice

The true measure of a fastener's performance lies in its real-world application. Our discount 16 d common nails have been instrumental in numerous projects, demonstrating their reliability and cost-effectiveness across diverse construction and industrial scenarios.

Case Study 1: Large-Scale Residential Development

A leading residential developer undertook a massive housing project involving hundreds of single-family homes. The primary challenge was to maintain rapid construction timelines while ensuring structural integrity and cost control. Our hot-dip galvanized 16 d common nails were selected for all framing and sheathing applications. The nails' consistent quality, high shear strength, and superior corrosion resistance ensured that all framed structures met stringent building codes and offered long-term durability, even in varied climatic zones. The bulk procurement model provided a 15% cost saving on fasteners compared to previous projects, contributing significantly to overall project profitability. Customer feedback highlighted the consistent quality and ease of use, minimizing tool jams and improving labor efficiency.

Case Study 2: Marine Facility Reconstruction

A marine industrial facility required reconstruction of several wooden jetties and boardwalks, demanding fasteners with extreme corrosion resistance. Standard bright nails would fail quickly in the saline environment. Our hot-dip galvanized 16 d common nails were specified for all timber connections. Independent lab testing confirmed the galvanized coating's adherence and thickness exceeded ASTM A153 requirements, projecting a service life of over 25 years even in direct salt spray exposure. This critical choice prevented premature structural failure and ensured the longevity and safety of the reconstructed facilities, providing a robust solution where conventional fasteners would have proven inadequate.

Fig. 3: Galvanized 16 d common nails providing robust, long-lasting connections in challenging outdoor environments.

Ensuring Trustworthiness: Quality, Support, and Logistics

Our commitment to our B2B partners extends beyond product delivery. We build trust through transparent operations, unwavering quality, and dedicated customer support.

Frequently Asked Questions (FAQ)

Q: What does "16 d" signify for common nails?

A: "16 d" (penny size) refers to the nail's length, which is typically 3 ½ inches (88.9 mm). It also implies a standard shank diameter for a nail of that length, indicating its use for heavy-duty construction.

Q: How do hot-dip galvanized nails compare to electro-galvanized for corrosion resistance?

A: Hot-dip galvanization provides a significantly thicker and more durable zinc coating, offering superior and longer-lasting corrosion resistance suitable for outdoor and harsh environments. Electro-galvanization provides a thinner, more aesthetic coating suitable for less aggressive conditions.

Q: Can these nails be used with pneumatic nail guns?

A: Our 16 d common nails are designed for both manual hammering and, where specified, are available in collated formats compatible with heavy-duty framing nailers. Please verify compatibility with your specific tool's requirements.

Lead Time and Fulfillment

We understand the critical nature of project timelines. Our standard lead time for bulk orders of discount 16 d common nails ranges from 2-4 weeks, depending on quantity and specific coating requirements. Expedited options are available for urgent requests. We maintain robust inventory levels for standard products and our streamlined logistics ensure efficient dispatch and delivery to your site or warehouse. Our global distribution network allows us to serve clients worldwide with reliable fulfillment.

Warranty Commitments

All our fasteners, including 16 d common nails, are backed by a comprehensive product warranty covering manufacturing defects and material integrity. Our hot-dip galvanized products come with an extended warranty against corrosion under normal application conditions, reflecting our confidence in their durability. Detailed warranty terms are provided with every order and are available upon request.

Customer Support and Technical Assistance

Our dedicated customer support team and technical specialists are available to assist with product selection, technical specifications, order inquiries, and post-purchase support. We offer direct communication channels, including phone, email, and dedicated account managers, to ensure prompt and effective resolution of any queries. We are proud of our ISO 9001 certification, underscoring our commitment to consistent quality management and customer satisfaction.

Conclusion and Strategic Partnership

The selection of fasteners is a critical determinant of project success. By choosing our discount 16 d common nails, B2B clients invest in a product that epitomizes strength, reliability, and cost-efficiency. Our dedication to quality manufacturing, adherence to global standards, and extensive range of related products—from discount 16.5g black annealed tie wire price to specialized oem anchor bolt grade 4.6—positions us as a strategic partner for comprehensive construction and industrial solutions. We are committed to fostering long-term relationships built on trust, technical excellence, and mutual growth, empowering our clients to achieve their most ambitious project goals with confidence.

References

- ASTM F1667, Standard Specification for Driven Fasteners: Nails, Spikes, and Staples. ASTM International, West Conshohocken, PA, 2017.

- ASTM A153, Standard Specification for Zinc Coating (Hot-Dip) on Iron and Steel Hardware. ASTM International, West Conshohocken, PA, 2016.

- ISO 9001:2015, Quality management systems — Requirements. International Organization for Standardization, Geneva, Switzerland, 2015.

- AISI/SAE Steel Grade Designations: Common Carbon Steel Grades. American Iron and Steel Institute / Society of Automotive Engineers.

-

Discount 16 d Common Nails - Bulk, Durable, Fast Shipping

NewsNov.17,2025

-

Finish Nails - Durable, Rust-Resistant, Clean Countersink

NewsNov.17,2025

-

Barbed Wire: Galvanized, High-Tensile Security Fencing

NewsNov.17,2025

-

Discount 16 d Common Nails – Bulk, Durable, OEM Options

NewsNov.17,2025

-

Welded Steel Tube Temporary Fence – Galvanized, Durable

NewsNov.04,2025

-

Barbed Wire – High-Tensile, Galvanized, Bulk & Fast Shipping

NewsNov.04,2025