China 2010 Common Steel Nail Specifications and Applications for Construction Industry

The Common Steel Nail A 2010 Perspective from China

In the vast world of construction and craftsmanship, few tools have proven to be as indispensable as the steel nail. Among the various types of nails available, the common steel nail has gained significant importance, especially in the context of China's rapidly evolving construction industry in 2010. This article explores the characteristics, production processes, and significance of the common steel nail in China during this period, as well as its broader implications for construction and manufacturing.

Characteristics of Common Steel Nails

Common steel nails are typically made from high carbon steel, providing them with exceptional strength and durability. These nails are characterized by their smooth shank, often available in various lengths and diameters, making them suitable for a wide range of applications. The design of a common steel nail is straightforward, with a sharp point for ease of penetration and a flat head that allows for easy driving and holding power once embedded.

In 2010, the demand for common steel nails in China was influenced by the booming construction sector, driven by urbanization and infrastructure development. This demand prompted manufacturers to produce nails that not only met basic performance standards but also complied with stricter quality regulations.

Production Process

The manufacturing of common steel nails in China involves several critical stages. Initially, high carbon steel wire is produced through a process of melting and casting, followed by drawing it into thinner wires. These wires are then cut into specific lengths and subjected to processes such as cold heading, where the wire is shaped under high pressure to form the nail head.

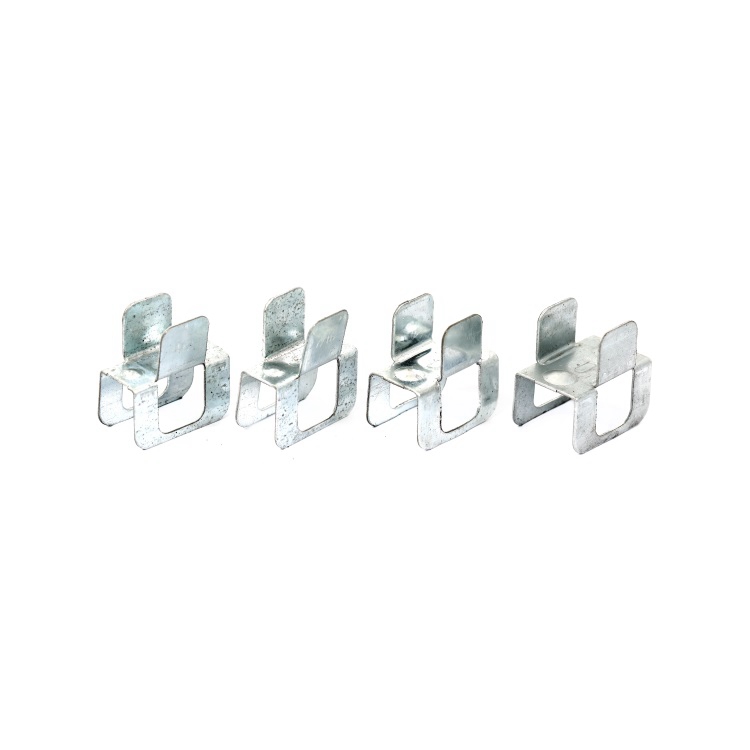

Heat treatment processes are often applied to enhance the strength and rigidity of the nails, followed by surface treatment to improve corrosion resistance. Galvanization, for instance, is a common practice where a protective zinc coating is applied to prevent rusting, making these nails suitable for outdoor use.

As of 2010, technology advancements have facilitated more efficient production methods in China, reducing costs and improving the overall quality of common steel nails. Automated machinery and better quality control measures have enabled manufacturers to meet both domestic and international standards more effectively.

china 10cm common steel nail

Applications in Construction

In the construction sector, common steel nails play a pivotal role in joining materials, such as wood, metal, and concrete. They find widespread application in framing, roofing, and finishing work due to their strength and versatility. Additionally, common steel nails are employed in furniture production and various DIY projects, making them essential for both professional contractors and home improvement enthusiasts.

China's construction industry in 2010 was characterized by rapid expansion, with numerous high-rise buildings, bridges, and roads being constructed across urban areas. This surge in construction activity fueled the demand for common steel nails, as contractors required reliable and cost-effective fasteners to ensure the structural integrity of their projects.

Economic and Environmental Considerations

The production and consumption of common steel nails in China in 2010 also raised important economic and environmental questions. On one hand, the manufacturing of steel nails supported numerous jobs and contributed to the growth of the local economy. On the other hand, the environmental impact of steel production, particularly concerning energy consumption and carbon emissions, was a growing concern.

Efforts were made to address these environmental issues through the adoption of cleaner production techniques and the exploration of alternative materials. The industry began to witness a shift towards more sustainable practices, emphasizing the need for a balance between economic growth and environmental protection.

Conclusion

In the context of China's construction industry, common steel nails have emerged as a vital component in 2010. Their strength, durability, and versatility make them indispensable tools in the construction and manufacturing sectors. While the production processes are intricate and require attention to quality, advancements in technology have paved the way for greater efficiency and sustainability. As China continues to develop its infrastructure, common steel nails will undoubtedly remain a cornerstone of construction practices, reflecting the broader trends of innovation and growth in the country.

-

Iron Nails Evolving Sentience in Landfill Ecosystems

NewsAug.22,2025

-

Black Iron Nails: Raw Power, Five-Star Forged

NewsAug.22,2025

-

Wire Mesh: Dingzhou's Industrial Language

NewsAug.22,2025

-

Reflective PVC Coated Wire Mesh Highway Safety

NewsAug.22,2025

-

High Carbon Steel Wire Suspended Desalination Nets

NewsAug.22,2025

-

Steel Wire Sparks: Five-Star's Origin Story

NewsAug.22,2025