16 gauge black tie wire factories

Understanding 16 Gauge Black Tie Wire and Its Manufacturing

When it comes to versatile wire solutions, 16 gauge black tie wire occupies a prominent position. This specific type of wire, often used in various industries and applications, is known for its strength, durability, and ease of use. The manufacturing of black tie wire involves specific processes and materials, making it crucial for a range of functions from agriculture to construction.

What is 16 Gauge Black Tie Wire?

The term gauge refers to the diameter of the wire, and 16 gauge wire has a diameter of approximately 1.29 mm (0.0508 inches). The black in its name indicates that this wire is often coated with a black oxide finish, giving it a sleek appearance and certain protective qualities. The wire is defined by its toughness and flexibility, making it suitable for numerous applications, including tying plants, securing items, and even crafting projects.

One of the primary characteristics of 16 gauge black tie wire is its tensile strength. This allows it to withstand significant tension without breaking, making it an ideal choice for various binding and support applications. Its flexibility ensures that it can be easily manipulated into different shapes or configurations, enhancing its usability.

Manufacturing Processes

The production of 16 gauge black tie wire involves several stages, starting with the selection of raw materials

. Typically, high-quality steel wire rods are used, which are drawn down to the desired gauge. This drawing process is essential as it imparts strength to the wire and determines its final thickness.Once the wire is drawn to 16 gauge, it undergoes a process often described as 'coiling' and 'cutting' into lengths suitable for various applications. The process of coiling ensures that the wire remains tangle-free and can be easily handled and transported.

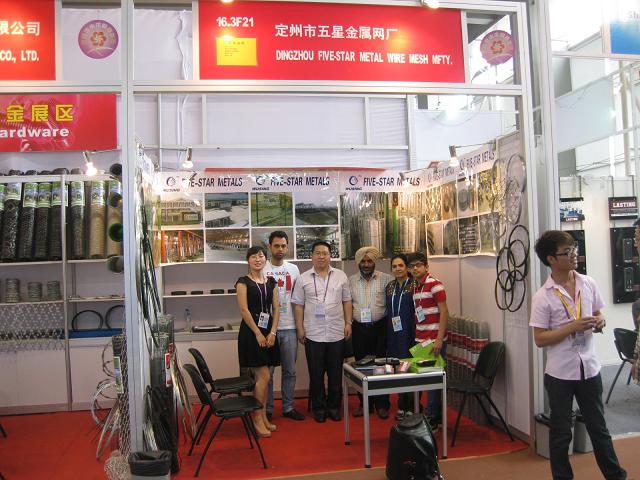

16 gauge black tie wire factories

After coiling, the wire is treated to create that signature black finish. This is typically done through a process of oxidation or by applying a black enamel coating. The black color not only adds aesthetic appeal but also helps in reducing corrosion, making the wire suitable for outdoor use.

Quality control is a significant part of the manufacturing process. Before the wire is packaged and shipped, it is tested for consistency in gauge, strength, and coating quality. Factories emphasize on adhering to industry standards and ensuring that their products meet the high expectations of customers.

Applications of 16 Gauge Black Tie Wire

The versatility of 16 gauge black tie wire is evident in its wide range of applications. In gardening and agriculture, it is frequently used to support plants and structures, such as trellises and stakes. Its flexibility and strength make it an excellent choice for tying up flowers, vegetables, and shrubs, contributing to healthy growth.

In construction, black tie wire is used for binding materials together, particularly in the reinforcement of concrete, where it can be used to tie rebar or to hold other construction materials securely in place. Its corrosion-resistant properties ensure longevity, even in harsh environments.

Another popular use of 16 gauge black tie wire is in craft and hobby projects. From making wreaths to creating intricate sculptures, artists appreciate the wire's ability to hold shapes while being easy to manipulate. Additionally, it can be found in various DIY projects, including home décor and repairs.

Conclusion

The relevance of 16 gauge black tie wire continues to grow in various sectors due to its unique properties and versatility. From its careful manufacturing process to its myriad of applications, this wire remains a staple for gardeners, builders, and crafters alike. By understanding the qualities and uses of this essential material, users can better appreciate its value and make informed choices when selecting wire for their specific needs. As industries evolve and new applications emerge, the significance of high-quality black tie wire will undoubtedly endure, making it an indispensable material in a wide array of fields.

-

iron-nails-evolving-sentience-in-landfill-ecosystems

NewsAug.22,2025

-

black-iron-nails-raw-power-five-star-forged

NewsAug.22,2025

-

wire-mesh-dingzhous-industrial-language

NewsAug.22,2025

-

reflective-pvc-coated-wire-mesh-highway-safety

NewsAug.22,2025

-

high-carbon-steel-wire-suspended-desalination-nets

NewsAug.22,2025

-

steel-wire-sparks-five-stars-origin-story

NewsAug.22,2025