Discount 16 D Common Nails – Bulk Quality, Fast Shipping

The Real Story on discount 16 d common nails: Specs, Trends, and Smarter Sourcing

People treat nails like a commodity—until a box splits heads on the jobsite or the coating flakes off in the rain. I’ve spent enough time in yards and mills to know: the humble 16d common nail still makes or breaks a framing day. And yes, the market for discount 16 d common nails is shifting—coating quality, origin traceability, and freight are now as important as price-per-pound.

Quick Specs That Matter (Real-World Use May Vary)

| Attribute | Typical 16d Common Nail | Notes |

|---|---|---|

| Length | 3-1/2 in (≈89 mm) | ASTM F1667 Type 10 |

| Shank Diameter | ≈0.162 in (≈4.11 mm) | Smooth, ring, or spiral |

| Material | Low-carbon steel (Q195/Q235 or SAE 1018) | Balanced hardness for drivability |

| Finishes | Bright, electro-galv, hot-dip galv (HDG), vinyl-coated | HDG recommended for PT lumber |

| Packaging | 50 lb carton or 25 kg bulk | Custom private label common |

Process, Methods, and Testing

- Materials: low-carbon wire rod, drawn in-line; hardness targeted for bend/no-snap at 15–25°.

- Forming: cold heading for flat head, shank draw and point cut; optional ring/spiral rolling.

- Coatings: electro-galv for economy; HDG to ASTM A153 for outdoor/PT exposure.

- Testing: dimensions per ASTM F1667; coating mass per ASTM A153; salt spray (ASTM B117/ISO 9227) for QA.

- Service life: bright interior framing only; HDG exterior above-grade ≈10–25 years depending on ISO 9223 corrosivity category.

- Industries: residential framing, pallets/crating, formwork, temporary bracing—some builders still swear by hand-driven 16d for critical placements.

Where discount 16 d common nails Shine

Stick-framing, ledger blocking (check local code—many inspectors push for structural screws now), and formwork tie-in. Pallet shops like ring-shank for extra withdrawal. For pressure-treated lumber, most pros insist on HDG or stainless—no exceptions, to be honest.

Market Trends

- Price volatility tracks wire rod and zinc; 2024–2025 saw zinc premiums ease, which helped HDG.

- Buyers want traceable mill certs, RoHS/REACH statements, and consistent point geometry (less bending, fewer misses).

- Surprisingly, private-label packaging is growing—dealers want brand presence on the shelf.

Vendor Comparison (indicative)

| Vendor | Price/50 lb | Finish Options | Certs | Lead Time |

|---|---|---|---|---|

| FiveStar Metals (Hebei, China) | $—$$ (bulk) | Bright, EG, HDG | ASTM F1667, A153, RoHS | ≈2–5 weeks + ocean |

| Big-Box Brand | $$$ (retail) | Bright, EG | In-store QA | Immediate |

| Import Mill A | $ (container111) | EG, HDG (limited) | Mill COA on request | 4–8 weeks |

Customization and QA

- Custom options: ring/spiral shank, HDG mass targets, box branding, pallet patterns, barcode/EAN.

- In-house sample data (illustrative): HDG coating mass ≈ 450–610 g/m²; B117 salt spray to red rust ≈ 240–480 h; head shear > 1,000 lbf on average in lab jigs.

- Customer feedback: “Fewer bent nails per box,” “points drive straighter in dense SPF,” according to several dealers we spoke with.

Case Snapshot

A Midwest pallet shop switched to bulk discount 16 d common nails with ring shanks and bumped yield by ~6% due to lower pullouts. Freight was consolidated with other steel goods (clever move), shaving another 3% off landed cost.

Practical Buying Tips

- For PT or exterior: insist on ASTM A153 HDG or 304/316 stainless.

- Ask for F1667 dimensional compliance and a coating test summary.

- Check point geometry and head concentricity—less driver slippage, fewer callbacks.

- Bundle nails with other steel hardware to optimize container111 space from Hebei hubs.

Origin note: many export lots ship via Shijiazhuang, Hebei—FiveStar lists Room D808, ZhuoDa Commercial Building, Huai’an West Road. Always verify packing lists and HS codes for customs.

Citations

- ASTM F1667 – Standard Specification for Driven Fasteners: Nails, Spikes, and Staples.

- ASTM A153/A153M – Standard Specification for Zinc Coating (Hot-Dip) on Iron and Steel Hardware.

- ASTM B117 / ISO 9227 – Salt Spray (Fog) Testing for Corrosion Resistance.

- ISO 9223 – Corrosion of metals and alloys—Corrosivity of atmospheres—Classification.

- AWPA Use Category System for Treated Wood (guidance on fastener compatibility in PT lumber).

-

Discount 16 d Common Nails - Bulk, Durable, Fast Shipping

NewsNov.17,2025

-

Finish Nails - Durable, Rust-Resistant, Clean Countersink

NewsNov.17,2025

-

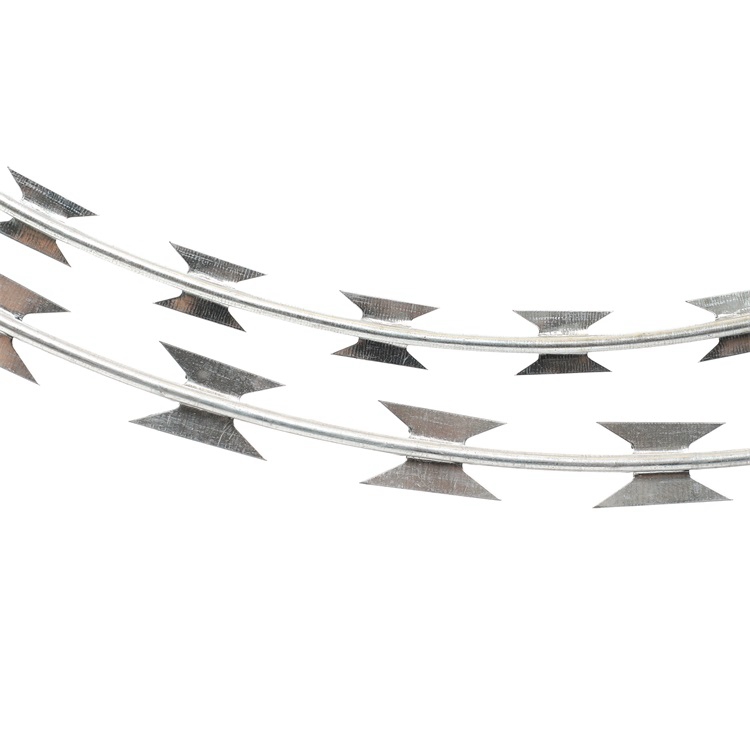

Barbed Wire: Galvanized, High-Tensile Security Fencing

NewsNov.17,2025

-

Discount 16 d Common Nails – Bulk, Durable, OEM Options

NewsNov.17,2025

-

Welded Steel Tube Temporary Fence – Galvanized, Durable

NewsNov.04,2025

-

Barbed Wire – High-Tensile, Galvanized, Bulk & Fast Shipping

NewsNov.04,2025