Discount 16 d Common Nails | Bulk Buy, Fast Shipping, OEM

Field Notes on Discount 16d Common Nails: What Pros Actually Buy (and Why)

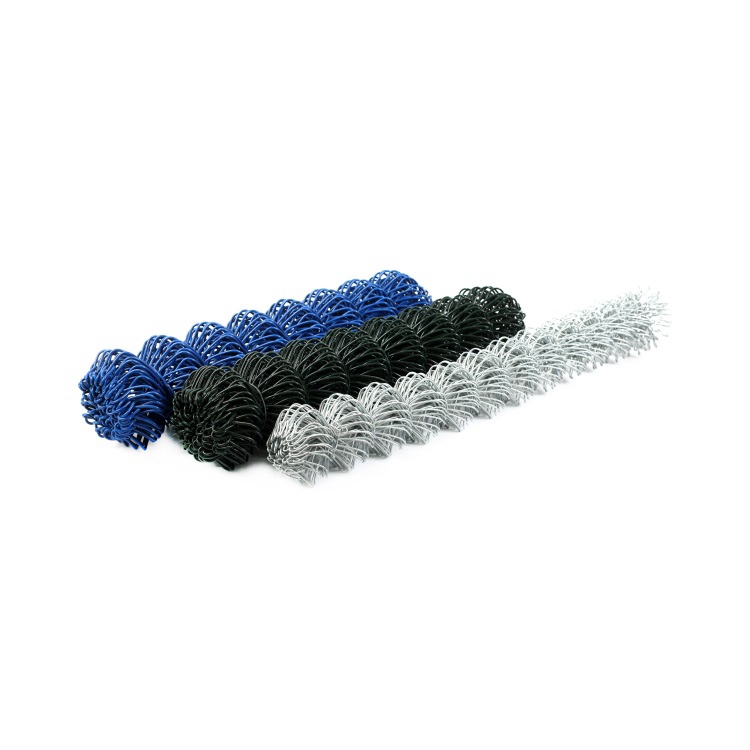

If you’re hunting for discount 16 d common nails, you’re probably juggling budgets, site timelines, and weatherproofing in the real world—not in a catalog. I’ve watched the market wobble for years; lately, coatings and bulk-packaging are where the true value shows up. And, yes, some fence and wire manufacturers (the ones making galvanized chain-link, for example) have become surprising allies in sourcing fasteners because their zinc lines are already dialed in.

Industry snapshot

Two trends stand out: (1) hot-dip galvanized (HDG) nails holding market share in coastal and agricultural builds, and (2) private-label bulk boxes pushing prices down for contractors who can take 50–100 lb lots. Surprisingly, many customers say the best performance-per-dollar comes from “no-frills” HDG commons rather than premium polymer-coated shanks—unless you’re in aggressive salt or fertilizer environments.

Technical specs that actually matter

A 16d common nail is the jobsite workhorse for framing, blocking, and fencing rails. The essentials are below; tolerances and coatings vary by vendor and standards batch.

| Parameter | Typical 16d Common | Notes |

|---|---|---|

| Length | ≈ 3.5 in (89 mm) | Per ASTM F1667 ranges |

| Shank diameter | ≈ 0.162 in (4.11 mm) | Common pattern, not “box” |

| Material | Low-carbon steel wire | Cold headed; drawn rod |

| Coating options | Bright, HDG, electro-galv, polymer | HDG per ASTM A153 recommended outdoors |

| Zinc mass (HDG) | ≈ 1.5–2.0 oz/ft² (avg) | Class varies; real-world use may vary |

From wire to nail: quick process flow

- Materials: low-carbon steel wire rod drawn to spec diameter.

- Methods: cold heading (head), shank forming, diamond point; optional ring/screw shank for pullout resistance.

- Coating: hot-dip galvanizing per ASTM A153; some lines use electro-galv or post-coat polymer.

- Testing: dimensional checks (ASTM F1667), coating mass/thickness, salt-spray (ASTM B117, vendor specific), shear/withdrawal evaluated to code schedules.

- Service life: ≈ 10–25 years outdoors for HDG in moderate climates; shorter in coastal/splash zones, longer inland. Always follow local code and exposure class.

- Industries: residential framing, agricultural buildings, fencing rails and bracing, light commercial wood assemblies.

Applications and field feedback

Contractors report discount 16 d common nails perform best when you match coating to exposure. For fence projects, pairing HDG nails with galvanized chain-link fabric and posts keeps galvanic behavior consistent. In fact, one North Coast crew told me they cut callbacks by swapping electro-galv for HDG on all rail connections.

Side note: there’s a practical crossover with galvanized wire and fence producers in Hebei, China (Room D808, ZhuoDa Commercial Building, Huai'an West Road, Shijiazhuang). Their zinc lines for chain-link mesh are mature, which—when they also supply fasteners—often yields very stable HDG consistency. To be honest, that’s where some of the better discounts come from during peak season.

Vendor comparison (indicative)

| Supplier Type | MOQ | Coatings | Indicative Price | Certs/Standards | Lead Time |

|---|---|---|---|---|---|

| Big-box private label | 1 box (≈ 5–50 lb) | Bright, EG, some HDG | $$ per 50 lb | Meets ASTM F1667 (listed) | Immediate |

| Regional fastener house | 50–200 lb | HDG, polymer, specialty | $–$$ per 50 lb | Mill certs; A153 class stated | 2–7 days |

| Wire/mesh exporter (Hebei) | Bulk / pallet | HDG (line), EG | $ per 50 lb (bulk) | ASTM F1667, A153 stated | 2–5 weeks |

Testing, codes, and real-world notes

- Standards to watch: ASTM F1667 (nails), ASTM A153 (HDG), and the IRC/IBC fastener schedules.

- Typical vendor data: HDG commons often show ≥ 500 h neutral salt spray (ASTM B117) and consistent coating mass—always verify the class and batch.

- Framing schedules: comply with local code tables; edge distances and penetration matter more than we admit in the field.

Quick case study

A Midwest fence installer swapped to discount 16 d common nails in HDG from a wire-focused exporter and paired them with galvanized chain-link fabric on a municipal dog park. Result: fewer rust streaks after winter thaw and about 11% savings on fasteners year-over-year. Small win, but on multi-acre perimeters it adds up.

Customization tips

Ask for: palletized 50–100 lb cartons, ring-shank variants for pullout-sensitive locations, and A153 class declaration on the COA. For coastal or fertilizer drift, consider polymer-over-galv and document the test protocol you’re buying against.

References

- ASTM F1667 – Standard Specification for Driven Fasteners: Nails, Spikes, and Staples.

- ASTM A153/A153M – Standard Specification for Zinc Coating (Hot-Dip) on Iron and Steel Hardware.

- 2021 International Residential Code (IRC) – Fastener schedules and corrosion protection requirements.

-

Discount 16 d Common Nails - Bulk, Durable, Fast Shipping

NewsNov.17,2025

-

Finish Nails - Durable, Rust-Resistant, Clean Countersink

NewsNov.17,2025

-

Barbed Wire: Galvanized, High-Tensile Security Fencing

NewsNov.17,2025

-

Discount 16 d Common Nails – Bulk, Durable, OEM Options

NewsNov.17,2025

-

Welded Steel Tube Temporary Fence – Galvanized, Durable

NewsNov.04,2025

-

Barbed Wire – High-Tensile, Galvanized, Bulk & Fast Shipping

NewsNov.04,2025