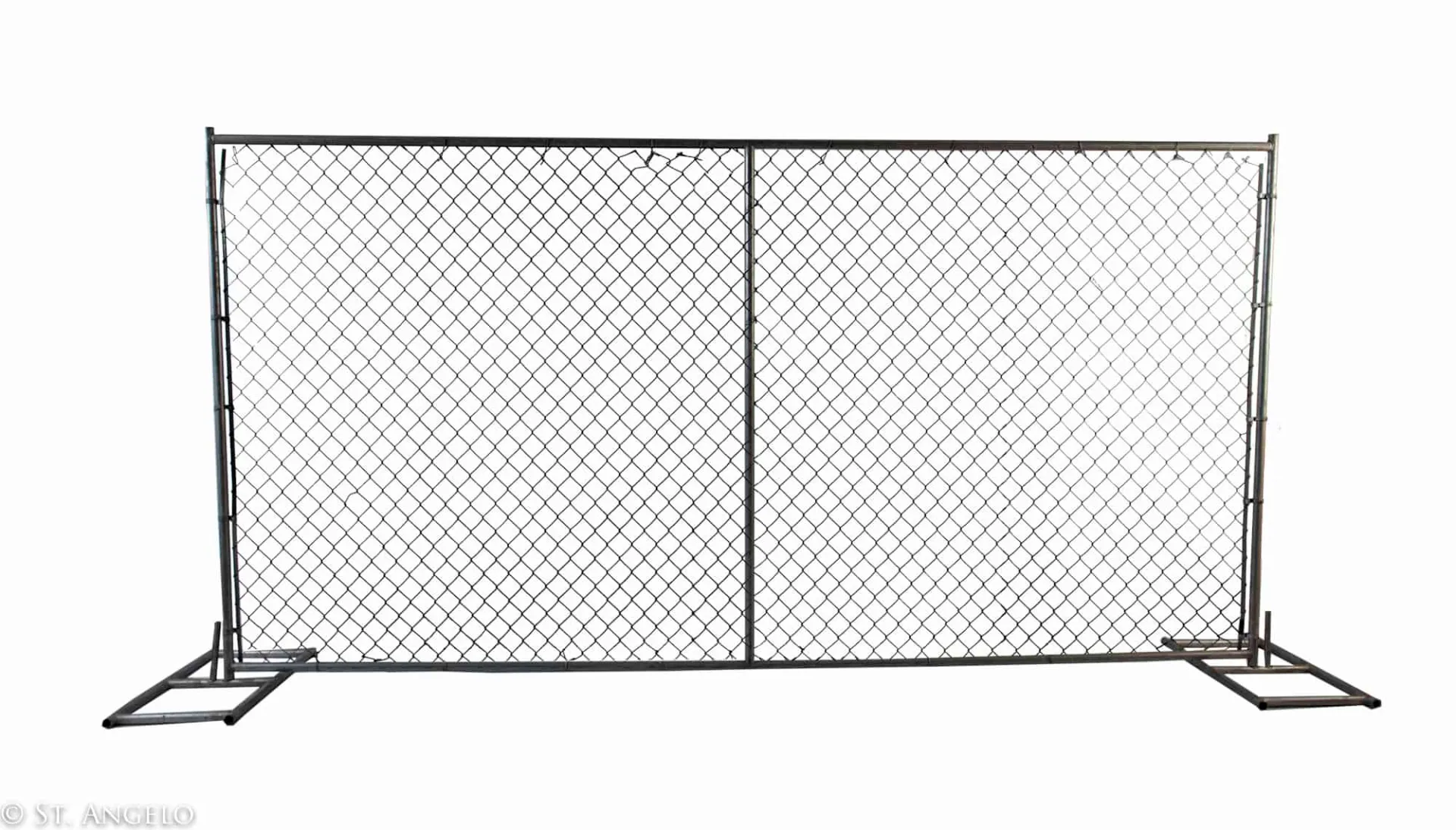

Woven Mesh Temporary Fence: Anti-Climb, Fast - Need It Now?

If you’ve spent time on construction sites, events, or quick-turn public works, you’ve probably bumped into the humble yet mighty Woven Mesh Temporary Fence. I’ve watched crews deploy it in minutes—then move it again before lunch. It’s not glamorous, but it quietly saves budgets and schedules. And yes, there’s more engineering behind it than most people think.

Where the market is heading

Two clear trends: higher coating quality (to survive more reuses) and safer wind-load performance. Event managers want cleaner lines and branded colors; contractors want panels that don’t bend after a rough week. Many customers say they now expect AS 4687 compliance and traceable galvanizing specs—five years ago, that was rare.

Core applications

- Construction perimeters, demolition buffers, and asset protection

- Crowd guidance at festivals, marathons, and fairs

- Hazard isolation around utilities, roadway work, and rail maintenance

- Short-term storage yards and emergency response zones

Typical specifications (field-proven)

| Panel size | ≈ 2.1 m (H) × 2.4 m (W) — real-world use may vary |

| Mesh opening | ≈ 60 × 60 mm woven mesh |

| Wire diameter | 2.5–3.15 mm low-carbon steel (ASTM A641 / EN 10244-2) |

| Frame tube | OD ≈ 32 mm, wall ≈ 1.5–2.0 mm, MIG-welded corners |

| Coating | Hot-dip galvanized after fabrication (ISO 1461), Zn ≥ 42 µm (≈ 300 g/m²) |

| Feet & clamps | UV-stabilized rubber feet; anti-tamper clamps with M10 bolts |

| Service life | 5–10 years depending on handling and coastal exposure |

| Test snapshot | Wind: panel + 2 rubber feet withstood ≈ 25–28 m/s gusts; Salt spray: 480 h (ASTM B117) no red rust on cut-edge |

Process flow (how it’s made)

Materials: low-carbon steel wire per ASTM A641/EN 10244-2; structural tubing per EN 10219.

Methods: wire drawing → zinc coating → woven mesh forming → frame cutting & MIG welding → hot-dip galvanizing (ISO 1461) → QC fitment → packaging.

Testing standards: AS 4687 stability checks; zinc coating thickness; weld integrity; dimensional tolerances; optional pull tests on mesh joins.

Industries served: construction, events, mining camps, public utilities, transport.

Why teams prefer Woven Mesh Temporary Fence

- Fast deployment; lighter than welded panels of similar strength

- Resilient under impact—woven pattern flexes instead of kinking

- Lower lifetime cost thanks to better reusability and repairability

- Compliance ready (AS 4687; OSHA barricade guidance where applicable)

Vendor comparison (shortlist)

| Vendor | Origin | Coating | Lead time | Certs | Notes |

|---|---|---|---|---|---|

| Fivestar Metals | Room D808, ZhuoDa Commercial Building, Huai'an West Road, Shijiazhuang, Hebei, China | Hot-dip after fab (≈ 42–70 µm) | ≈ 3–5 weeks | ISO 9001; AS 4687 test reports | Strong QC; customization-friendly |

| Importer A | Mixed APAC | Pre-galv + paint | ≈ 6–8 weeks | Basic CoC | Lower upfront cost; shorter life |

| Local Rental B | Regional | Mixed used stock | Ready stock | N/A | Great for short-term, limited spec control |

Customization

Panel widths, wire gauges, hot-dip thickness, powder topcoats, branded screens, anti-lift feet, and anti-climb mesh are all on the menu. I’ve seen teams add QR-coded tags for inventory—surprisingly helpful.

Real-world notes

- Case 1: Coastal project—panels with ISO 1461 galvanizing outlasted painted sets by ≈ 2–3 seasons.

- Case 2: Music festival—switching to Woven Mesh Temporary Fence reduced setup time by ~22% vs heavier welded panels.

To be honest, the difference between “okay” and “great” fencing is in the coating and clamps. If you’re speccing, ask for coating certificates and a quick wind-stability note referencing AS 4687. It seems that the teams who do that rarely deal with mid-event repairs.

Authoritative references

- AS 4687:2007 Temporary fencing and hoardings.

- ISO 1461:2022 Hot dip galvanized coatings on fabricated iron and steel articles.

- ASTM A641/A641M Zinc-Coated (Galvanized) Carbon Steel Wire.

- EN 10244-2:2009 Non-ferrous metallic coatings on steel wire.

- OSHA 29 CFR 1926 Subpart G — Signs, Signals, and Barricades.

-

Discount 16 d Common Nails - Bulk, Durable, Fast Shipping

NewsNov.17,2025

-

Finish Nails - Durable, Rust-Resistant, Clean Countersink

NewsNov.17,2025

-

Barbed Wire: Galvanized, High-Tensile Security Fencing

NewsNov.17,2025

-

Discount 16 d Common Nails – Bulk, Durable, OEM Options

NewsNov.17,2025

-

Welded Steel Tube Temporary Fence – Galvanized, Durable

NewsNov.04,2025

-

Barbed Wire – High-Tensile, Galvanized, Bulk & Fast Shipping

NewsNov.04,2025