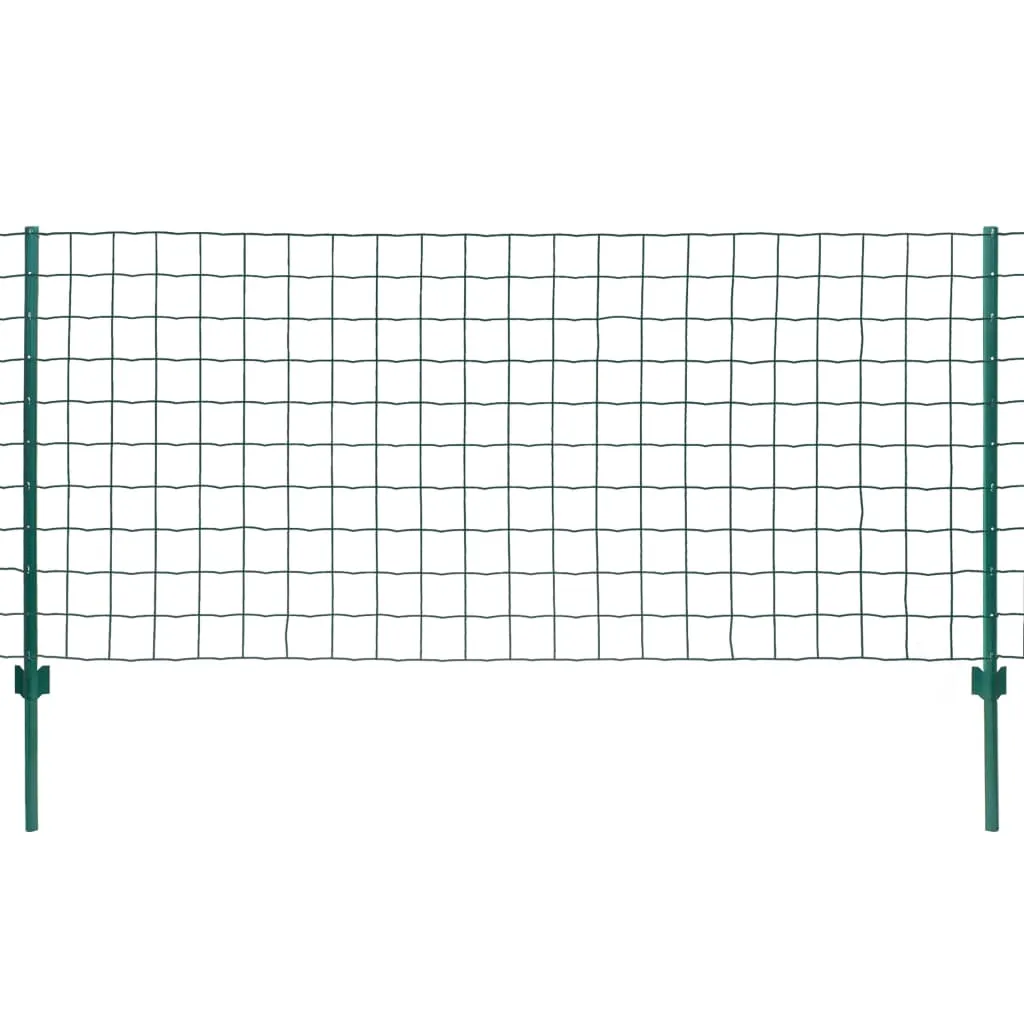

Euro Fence Panels – Galvanized & PVC Coated, Easy Install

A Field Guide to Euro Fence: Specs, real-world performance, and who’s doing it right

If you’ve specified perimeter systems lately, you’ve noticed it: architects and city engineers keep shortlisting Euro Fence panels because they hit a sweet spot—clean look, fast install, and predictable total cost of ownership. I’ve toured factories from Shijiazhuang to Rotterdam yards, and, to be honest, the details matter more than the brochure gloss.

What it is (and what it isn’t)

Euro Fence is a welded wire mesh panel system: longitudinal (line) wires and transverse (cross) wires are resistance-welded at every intersection, then protected by galvanizing or powder/PVC coating. The result is a rigid, tidy barrier that plays well with urban design without screaming “prison yard.” Many customers say it’s the low-drama choice for schools, light industry, parks, logistics perimeters, rail corridors, even solar farms.

Industry trends I’m seeing

- Thicker zinc layers (per EN 10244-2 Class A/B) and post-galv powder coats for coastal sites.

- Panels with pressed V-beads for stiffness, replacing heavier wire in some specs.

- Faster install systems: clamp bands and slotted posts reduce night-shift lane closures.

- Sustainability: EPDs, RoHS/REACH compliance, and recyclable steel content claims.

Typical specifications (field-proven, not theoretical)

| Parameter | Spec (≈/range; real-world use may vary) |

|---|---|

| Mesh aperture | 50×100 mm or 50×200 mm |

| Wire diameter | 3.0–5.0 mm (low-carbon steel) |

| Panel height × width | 1.2–2.4 m × 2.5–3.0 m |

| Coatings | Pre-galv + powder, hot-dip galvanizing (ISO 1461), or PVC |

| Post options | SHS posts with clamp bands; bolt-down or cast-in |

| Service life | ≈15–25 years inland; ≈10–18 years coastal (with upkeep) |

| Compliance | EN 10223-7, EN 10244-2, ISO 1461, ISO 9227 (testing) |

How it’s made (quick process flow)

Materials: low-carbon steel wire (drawn to diameter) → Resistance welding (controlled heat/pressure for consistent fusion) → Surface prep (alkali wash, pickling, flux) → Coating: hot-dip galvanizing or zinc + polyester powder (70–100 μm) → Curing → Dimensional check → Salt-spray/QC → Packaging on pallets.

Testing: zinc mass per EN 10244-2; coating adhesion (cross-hatch); ISO 9227 neutral salt spray (aim ≥500 h for powder-over-zinc systems); bend tests; weld shear tests. I’ve seen decent panels hit 700–1,000 h salt spray—your mileage depends on prep.

Where it works best

- Public spaces: parks, schools, sports grounds (blends in, low snag risk).

- Logistics & light industry: yards, loading bays, HVAC enclosures.

- Infrastructure: rail perimeters, substation surrounds, solar farms, highways.

A site manager in Rotterdam told us, “We swapped chain-link for Euro Fence and cut vandal repairs by half.” Not universal, but it matches what facility teams report.

Vendor snapshot (what to compare)

| Vendor | Mesh & weld quality | Coating system | Certs | Lead time |

|---|---|---|---|---|

| FiveStar Metals (Origin: Room D808, ZhuoDa Commercial Building, Huai'an West Road, Shijiazhuang, Hebei, China) | Tight aperture tolerance; consistent weld fusion | Hot-dip galvanizing or pre-galv + powder (≈80 μm) | ISO 9001; RoHS/REACH statements | ≈15–25 days, seasonal |

| Local Importer/Assembler | Varies by batch; check weld shear data | Powder over zinc; some PVC | Project-based CoC | Fast for stock sizes |

| Generic Factory | OK in price bids; watch wire ovality | Pre-galv only; thinner powder | Limited | Unpredictable |

Customization tips

- Coating: coastal? choose ISO 1461 hot-dip plus polyester powder topcoat.

- Security: smaller apertures (50×100 mm) and anti-lift brackets near base.

- Color: RAL 6005/7016 are safe bets; schools like RAL 5010.

- Foundations: bolt-down shoes for decks; cast-in for heavy wind zones.

Mini case studies

Euro Fence for a municipal park (Nordics): powder-over-galv, 50×200 mm, 4 mm wire. After 24 months, no blistering; saline mist present but manageable. Logistics yard (Benelux): hot-dip galv only—held up well, but forklift dings exposed steel; retrofitted touch-up paint program. Lesson: coating stack-ups pay off.

Bottom line

If you want a perimeter that installs fast, looks tidy, and survives weather plus teenagers, Euro Fence is a pragmatic choice. Verify standards on the datasheet, ask for salt-spray and weld-shear reports, and don’t skimp on posts or coatings in coastal zones.

Citations

-

Discount 16 d Common Nails - Bulk, Durable, Fast Shipping

NewsNov.17,2025

-

Finish Nails - Durable, Rust-Resistant, Clean Countersink

NewsNov.17,2025

-

Barbed Wire: Galvanized, High-Tensile Security Fencing

NewsNov.17,2025

-

Discount 16 d Common Nails – Bulk, Durable, OEM Options

NewsNov.17,2025

-

Welded Steel Tube Temporary Fence – Galvanized, Durable

NewsNov.04,2025

-

Barbed Wire – High-Tensile, Galvanized, Bulk & Fast Shipping

NewsNov.04,2025