Discount 16 d Common Nails - Bulk Savings, Fast Shipping

A Field Guide to Discount 16d Common Nails: Specs, Trends, and Real-World Buying Advice

If you’re shopping for discount 16 d common nails, you’re probably balancing price, code compliance, and corrosion resistance. I’ve spent enough time on job sites and in yards to know the “cheap vs. reliable” tension is real. And, actually, one overlooked angle is accessory hardware—like galvanized plywood H-clips—which often ships from the same factories and gives you a window into a vendor’s quality culture.

What’s changing in the nail market

Two trends: (1) more builders are insisting on documented ASTM and IRC compliance even for bargain nails, and (2) coatings are getting smarter—hybrid zinc plus polymer finishes that outperform basic electro-galv in coastal jobs. To be honest, the price gap between “discount” and “brand” narrows when you factor rework and rust callbacks.

Technical quick specs for 16d common nails

| Length | ≈ 3.5 in (89 mm) |

| Shank diameter | ≈ 0.162 in (4.11 mm) |

| Steel grade | Low-carbon, drawn wire (e.g., SAE 1006–1018), real-world use may vary |

| Coatings | Bright, electro-galv, hot-dip galvanized per ASTM A153, or polymer/cement-coated |

| Head type | Flat, checkered; loose nail (not collated) |

| Standards | ASTM F1667; corrosion tests often ASTM B117; IRC/IBC nailing schedules |

Applications and accessories

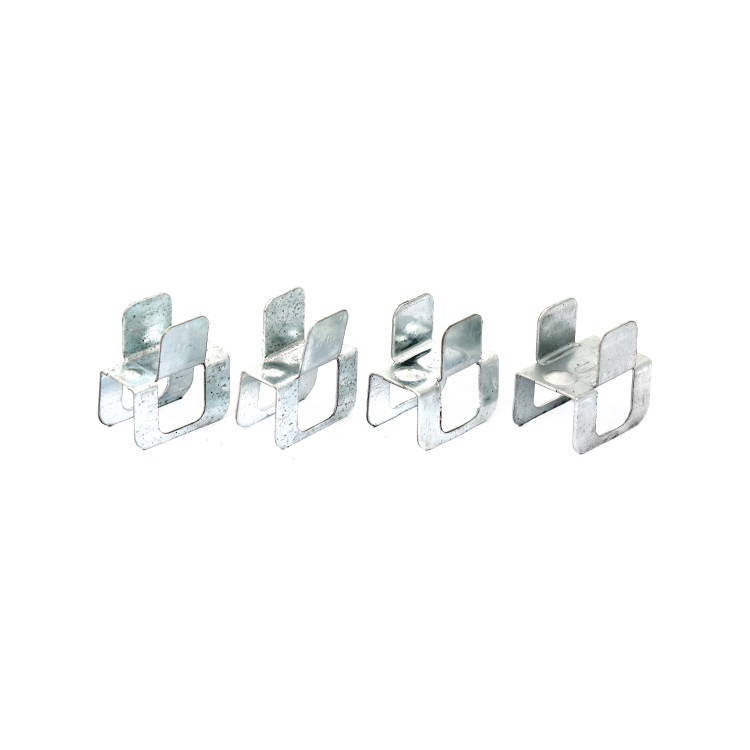

Framing, sheathing, blocking, and crate/pallet assembly. In roof and wall sheathing, many crews pair 16d commons with galvanized plywood H-clips for panel edge support—those clips prevent “panel kiss” and stiffen spans. Five Star Metals’ galvanized Plywood Clips (H-Clips) are made in Hebei, China (Room D808, ZhuoDa Commercial Building, Huai’an West Road, Shijiazhuang) and, in my experience, arrive straight and consistent—small detail, big difference when you’re sheathing fast.

Process flow (how good nails are made)

Wire rod → pickling/lubrication → multi-stage wire drawing → cold heading (head formation) → point forming → optional ring/screw shank → cleaning → coating (electro-galv or hot-dip) → QC: dimensional checks, bend test (ASTM F1667), coating mass (ASTM A153), and salt-spray snapshots (ASTM B117). Service life: around 5–25 years depending on coating and environment; coastal zones need thicker zinc or stainless, to be honest.

Vendor comparison (typical market snapshot)

| Vendor | Material/Coating | Price/lb (≈) | QC/Certs | Lead Time | Notes |

|---|---|---|---|---|---|

| Five Star Metals | Low-carbon steel; hot-dip or electro-galv | $0.85–$1.05 | ISO 9001, ASTM lot test reports | 2–5 weeks | Strong on accessories (H-clips), stable zinc mass |

| Regional Yard A | Electro-galv | $1.10–$1.25 | Mill cert on request | Stock | Easy returns; mixed origin |

| Importer B | Bright steel | $0.70–$0.85 | Basic QC only | 4–8 weeks | Cheapest, but watch for rust in storage |

Customization and testing

- Options: ring/screw shank for higher withdrawal, cement coating, bulk or collated equivalents.

- Testing: bend angle ≥ 90° without fracture (per ASTM F1667 guidance); coating mass verified per ASTM A153; withdrawal tested in SPF or DF per ASTM D1761 data methods.

- Service data: sample salt-spray to 72–240 h (B117) for comparative screening—real-world results depend on site conditions.

Case study: cutting cost without callbacks

A mid-size framer in the Midwest switched to discount 16 d common nails with hot-dip galvanizing and paired galvanized H-clips on roof decks. Result: ~9% material savings, zero rust streaks at 12-month walkthrough, and inspectors signed off easily thanks to ASTM and IRC references on the packing slip. Many customers say the clincher is consistent shank diameter—gun jams and split studs cost more than the nickel you saved per pound.

Final buying notes

For discount 16 d common nails, ask for: ASTM F1667 conformance, coating spec (A153 Class D or equivalent for exterior), withdrawal data or bend test summaries, and ISO 9001 at the plant. And yes, grab matching galvanized H-clips for sheathing—surprisingly, accessory quality is a solid proxy for nail QC.

References

- ASTM F1667 – Standard Specification for Driven Fasteners: Nails, Spikes, and Staples.

- ASTM A153/A153M – Zinc Coating (Hot-Dip) on Iron and Steel Hardware.

- ASTM B117 – Standard Practice for Operating Salt Spray (Fog) Apparatus.

- 2021 International Residential Code (IRC), Table R602.3(1) Nailing Schedule.

-

Discount 16 d Common Nails - Bulk, Durable, Fast Shipping

NewsNov.17,2025

-

Finish Nails - Durable, Rust-Resistant, Clean Countersink

NewsNov.17,2025

-

Barbed Wire: Galvanized, High-Tensile Security Fencing

NewsNov.17,2025

-

Discount 16 d Common Nails – Bulk, Durable, OEM Options

NewsNov.17,2025

-

Welded Steel Tube Temporary Fence – Galvanized, Durable

NewsNov.04,2025

-

Barbed Wire – High-Tensile, Galvanized, Bulk & Fast Shipping

NewsNov.04,2025