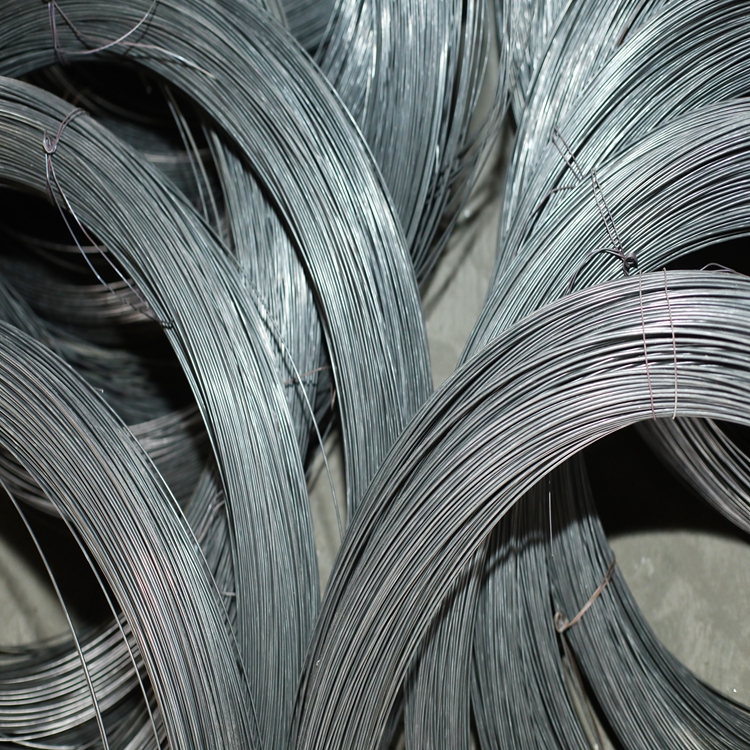

High carbon black annealed iron steel wire

Product Description

Annealed wire has good elasticity and flexibility, and its softness and hardness can be controlled during the annealing process. It is made of high-quality iron wire and is mainly used in the construction industry as binding wire. The main wire sizes are 4#-25# (silk warp 0.5-6mm), which is softer than ordinary black iron wire, with stronger flexibility, uniform softness and uniform color.

Parameter

|

Wire Diameter |

Tensile Strength |

Packing Weight |

|

|

bwg |

mm |

mpa |

kg |

|

25-4 |

0.5-6 |

30-55 |

1-1000 |

Features

- Various weights and dimensions.

Excellent flexibility and softness.

Bright and smooth surface.

Anti-corrosion and anti-oxidation.

Long service life. - We have test this products many years,it’s high performance,durable,convenient to operate, it’s a proven technology.

Application

Since annealed wire has different chemical and physical properties than regular steel, it provides a few advantages in some applications. The annealed wire manufacturing process gives it the flexibility necessary in many industries, including agriculture, construction, manufacturing and more.

Baling: Agricultural companies use annealed wire for baling hay, branches and other materials. Annealed wire is ideal for these applications because it is sturdy, yet flexible. Annealed wire will also stay in place once bent to a specific shape.

Tying: Annealed steel wire can help secure various items by stretching and expanding. For example, recycling centers tie bundles of scrap paper, cardboard and metal with annealed wire. Manufacturers also use annealed wire to bind, bale and tie their materials and products.

Packaging: Product manufacturers use annealed wire to secure packages during shipping because the wire provides security and flexibility. Some facilities also use the material in wire mesh to create packaging molds.

Securing equipment: The mining industry sometimes uses annealed wire to hold equipment in place.