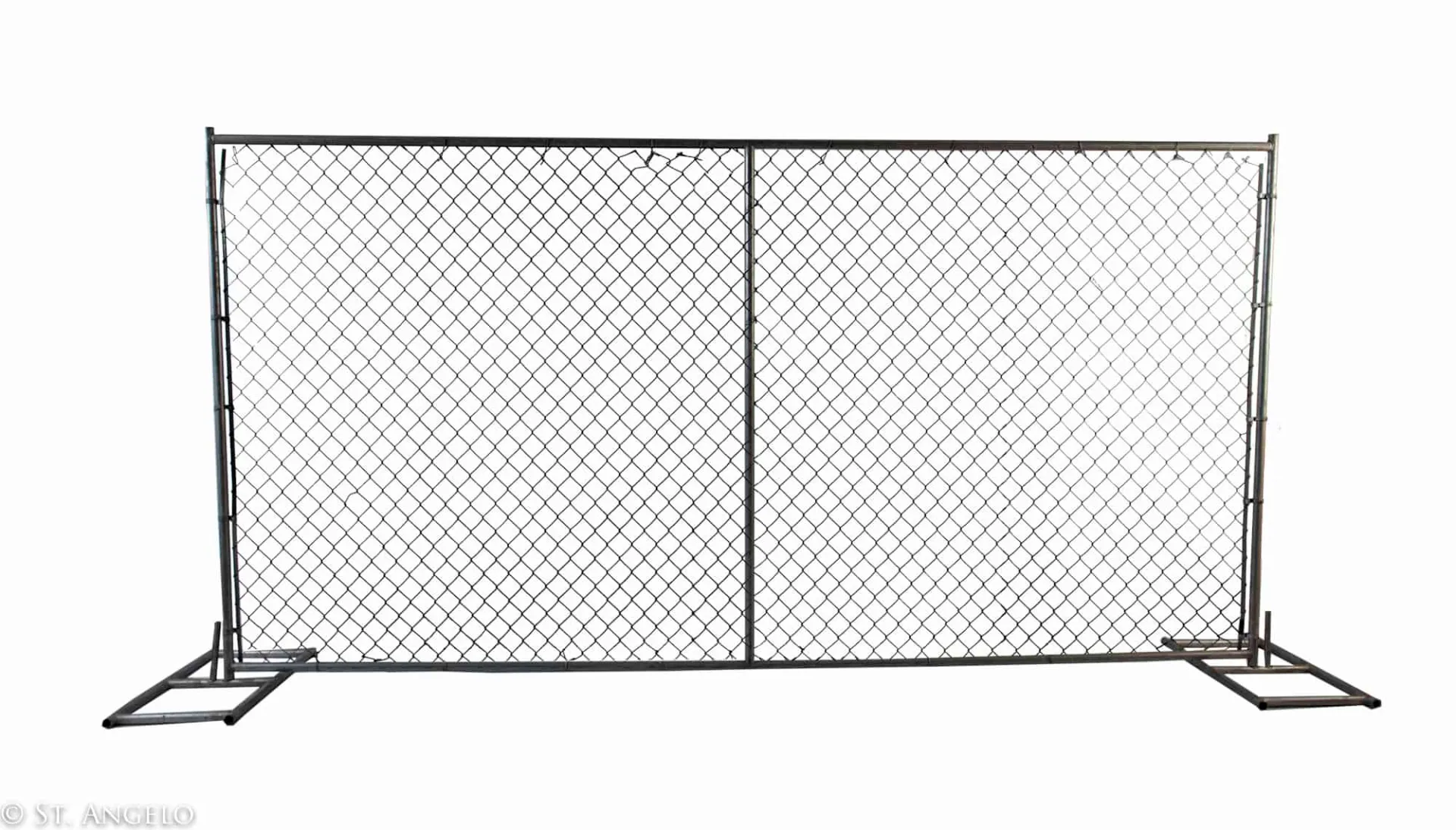

Woven Mesh Temporary Fence: Anti-Climb, Fast Setup?

Woven Mesh Temporary Fence: the quiet workhorse of modern sites

If you’re weighing safety, speed, and spend, the Woven Mesh Temporary Fence has probably crossed your desk. On the ground—at events, construction portals, pop-up logistics yards—this fence shows up because it’s practical, not flashy. I’ve seen it survive wind, unplanned forklift nudges, and the occasional over-enthusiastic crowd. It’s become an industry staple for a reason.

What’s trending (and why it matters)

Three shifts keep coming up in buyer calls: higher zinc thickness for longer service life, safer anti-trip bases, and faster tool-free connections. Also, rental companies want panels that stack tighter (freight’s not getting cheaper). To be honest, sustainability questions are louder too—recyclable steel and coatings with fewer VOCs are getting more attention than ever.

Technical snapshot and real-world specs

| Spec | Typical Value (≈, real use may vary) |

|---|---|

| Panel size | ≈ 2.1 m H × 2.4 m W |

| Mesh aperture | 60 × 150 mm woven mesh |

| Wire diameter | 2.8–3.5 mm (low-carbon steel) |

| Frame tube | Ø32–40 mm × 1.5–2.0 mm |

| Finish | Hot-dip galvanized (ISO 1461) or powder-coated |

| Bases | Recycled rubber or concrete-filled HDPE |

| Clamps | Pressed steel, galvanised; pull test ≥ 1.2 kN |

| Service life | Up to 10–12 years (coastal: ≈ 6–8) |

| Standards | AS 4687, EN 10244-2, ISO 1461, ASTM A123/A153 |

How it’s made (quick process flow)

- Materials: Q195 low-carbon steel wire and ERW steel tube frames.

- Methods: woven mesh interlocking; frames cut, mitre-welded, then mesh tied-in at nodes.

- Coatings: hot-dip galvanizing (avg. zinc layer ≈ 70–100 μm) or polyester powder coat over zinc.

- Testing: salt spray ASTM B117 ≥ 500 h; clamp pull ≥ 1.2 kN; panel deflection at 400 N load < 10 mm.

- Traceability: batch stamp + QA record; factory from Shijiazhuang, Hebei, China (Room D808, ZhuoDa Commercial Building, Huai'an West Road).

Where it shines

Construction perimeters, crowd guidance at festivals, emergency cordons, municipal works, short-term logistics yards, wind-farm staging—anywhere you need fast, modular control. Many customers say the Woven Mesh Temporary Fence feels lighter than welded mesh equivalents without losing rigidity, which lines up with my site checks.

Why woven mesh?

- Resilience: woven nodes flex slightly under impact, reducing permanent deformation.

- Speed: tool-free clamps; two-person install is normal.

- Lower TCO: fewer panel replacements; stackable bases save freight.

- Safety: anti-climb aperture and hi-vis base ends reduce trip incidents.

Vendor snapshot (what buyers actually compare)

| Vendor | Coating | Lead Time | Certs | Customization | Price Index |

|---|---|---|---|---|---|

| FiveStar Metals (Woven Mesh Temporary Fence) | HDG ISO 1461 / powder over zinc | ≈ 15–25 days | ISO 9001, AS 4687 test reports | Panel size, color, base, branding | $$ (value) |

| Generic Importer | Electro-galv (thin) | ≈ 30–45 days | Limited | Basic only | $ (low) |

| Local Rental Brand | Mixed fleets | In stock | Site-compliance docs | Limited | $$$ (rental) |

Customization

Choose your mesh aperture for anti-climb, color-match powder coat to brand or site zoning, add anti-lift brackets, wind-bracing bars, debris screens, and serialized tags. Real-world pro tip: go heavier on zinc if coastal or near chemical plants.

Field notes and mini case studies

- Wind farm laydown, NSW: 800 m run with bracing at 20 m intervals; zero panel failures after two storms (gusts ≈ 26 m/s).

- City festival, Midwest US: powder-coated hi-vis panels cut egress confusion; operations team reported 15% faster nightly teardown.

Feedback sounds consistent: “clamps bite well,” “bases don’t crumble,” and—my favorite—“less rattling on trucks.” Hard to quantify, but it matters.

Compliance and testing notes

Panels are built around AS 4687 performance for temporary fencing and barricades, with galvanizing per ISO 1461 / ASTM A123. Wire coatings align with EN 10244-2; corrosion verified via ASTM B117 salt spray. Site use should still follow local safety codes and OSHA barricade guidance.

Authoritative citations:

- ISO 1461: Hot dip galvanized coatings on fabricated iron and steel articles.

- ASTM A123/A153: Zinc (Hot-Dip Galvanized) Coatings on Iron and Steel Products.

- EN 10244-2: Steel wire and wire products — Non-ferrous metallic coatings.

- AS 4687: Temporary fencing and hoardings — Performance and requirements.

- ASTM B117: Standard Practice for Operating Salt Spray (Fog) Apparatus.

-

Discount 16 d Common Nails - Bulk, Durable, Fast Shipping

NewsNov.17,2025

-

Finish Nails - Durable, Rust-Resistant, Clean Countersink

NewsNov.17,2025

-

Barbed Wire: Galvanized, High-Tensile Security Fencing

NewsNov.17,2025

-

Discount 16 d Common Nails – Bulk, Durable, OEM Options

NewsNov.17,2025

-

Welded Steel Tube Temporary Fence – Galvanized, Durable

NewsNov.04,2025

-

Barbed Wire – High-Tensile, Galvanized, Bulk & Fast Shipping

NewsNov.04,2025