M42 Anchor Bolts Manufacturer for Heavy-Duty Construction Applications and Custom Solutions

The Importance of M42 Anchor Bolts in Construction A Focus on Manufacturing

In the world of construction, the integrity of structures hinges on the quality and reliability of the materials used. Among these materials, anchor bolts play a crucial role, especially M42 anchor bolts. These bolts are essential components that provide the strength and stability required for securing structural elements. This article explores the significance of M42 anchor bolts and the manufacturing processes that ensure their quality.

Understanding M42 Anchor Bolts

M42 anchor bolts, a designation that signifies a specific diameter of 42 millimeters, are primarily used in heavy-duty applications. They are often embedded into concrete and serve as a critical means of connecting various elements of a structure, such as columns, beams, and machinery. The robust nature of these bolts makes them ideal for environments subject to high loads and dynamic forces, such as seismic zones or heavy industrial settings.

Given their importance, it is necessary to understand the manufacturing processes behind M42 anchor bolts. The production of these bolts involves several steps, including material selection, forging, machining, heat treatment, and surface finishing. Each stage is vital to ensure the final product meets industry standards and performs optimally under stress.

Material Selection

The first step in manufacturing M42 anchor bolts involves choosing the right materials. Typically, high-strength carbon steel or alloy steel is selected depending on the specific requirements of the application. The material must exhibit excellent tensile strength, ductility, and fatigue resistance to withstand the various forces it may encounter. Manufacturers often opt for materials that comply with international standards such as ASTM or ISO to ensure quality and performance.

Forging Process

Once the material is selected, the next step is forging. This process involves heating the steel to a high temperature and then shaping it under immense pressure. Forging is crucial as it improves the grain structure of the metal, enhancing its mechanical properties. The M42 bolts are typically forged into their rough shape, which allows for greater precision during the subsequent machining phase.

m42 anchor bolts factory

Machining and Threading

After forging, the anchor bolts undergo machining to achieve the desired dimensions and surface finish. This process includes cutting, grinding, and boring to refine the bolt's shape accurately. A critical aspect during this phase is the creation of threads. The threading on the M42 anchor bolts must be precise, as it directly affects how the bolts will engage with other structural components. High-quality machining ensures that the threads are uniform and free from defects.

Heat Treatment

Heat treatment is another essential step in the manufacturing process. This procedure involves heating the forged and machined bolts to a specific temperature and then cooling them in a controlled manner. Heat treatment serves to increase the hardness and strength of the anchor bolts, preparing them for the demands they will face in the field. This step is crucial, as improperly heat-treated bolts may fail under load, leading to catastrophic failures in construction.

Surface Finishing

The final step in the production of M42 anchor bolts is surface finishing. This process ensures that the bolts are free from imperfections and corrosion-resistant. Common methods include galvanizing, coating, or applying protective films. Proper surface finishing not only enhances the aesthetic appeal of the bolts but also extends their lifespan by protecting them from environmental factors such as moisture and chemicals.

Conclusion

In conclusion, M42 anchor bolts are indispensable in ensuring the safety and stability of various structures. The meticulous manufacturing process, which encompasses material selection, forging, machining, heat treatment, and surface finishing, is crucial in producing high-quality anchor bolts that can withstand demanding conditions. As construction practices evolve, the importance of relying on dependable components like M42 anchor bolts remains ever significant. By understanding the manufacturing intricacies, stakeholders can make informed decisions that contribute to successful construction projects.

-

The Durability and Versatility of Steel Wire

NewsJun.26,2025

-

The Best Iron Nails for Your Construction Projects

NewsJun.26,2025

-

Strengthen Your Projects with Durable Metal Stakes

NewsJun.26,2025

-

Get the Job Done Right with Duplex Nails

NewsJun.26,2025

-

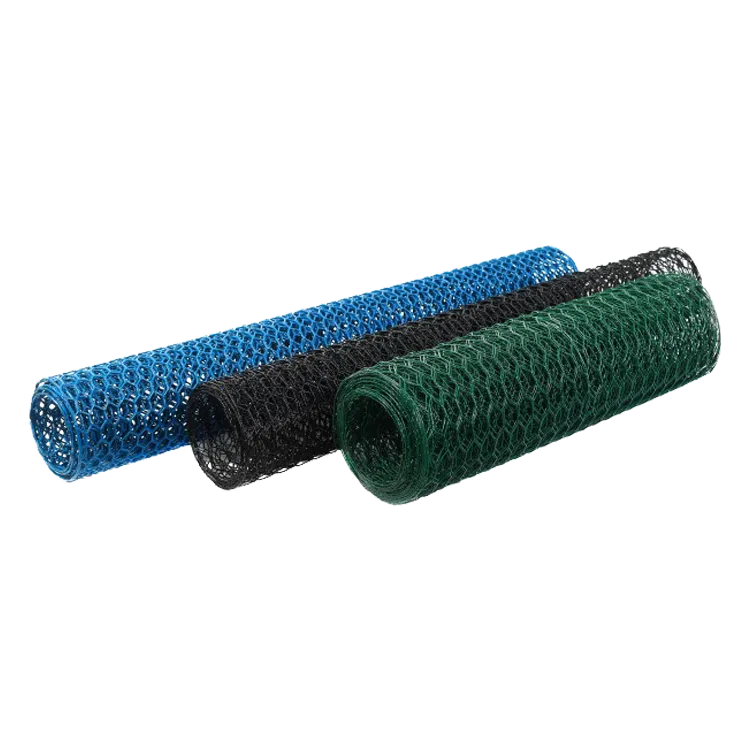

Explore the Versatility and Strength of Metal Mesh

NewsJun.26,2025

-

Enhance Your Security with Razor Wire

NewsJun.26,2025