Feb . 20, 2025 00:46

Back to list

3 inch concrete nails

Concrete nails, specifically the 3-inch variant, serve as a cornerstone in the world of construction and carpentry. Designed to penetrate rigid concrete surfaces, their role is invaluable in both professional and DIY projects. Understanding their application, benefits, and best usage practices is crucial for anyone involved in concrete work.

The application of 3-inch concrete nails extends to numerous industry examples, bolstering their authoritative use. For instance, in carpentry, they're essential for framing in basements where wooden structures meet concrete floors or walls. In commercial construction, these nails help in the installation of rigid insulation panels or metal tracks, providing a basis for laying drywall. They are also prevalent in the mounting of fixtures and fittings where direct attachment to a concrete surface is required. Trustworthiness in using 3-inch concrete nails stems from their longstanding use in construction and their ability to meet standardized building codes. The nails provide a cost-effective solution with a proven track record, reinforcing their reliable choice among builders and contractors. Adopting best practices in the usage of concrete nails ensures not only the structural integrity of a project but also safety. It is critical to adhere to safety guidelines, such as using protective eyewear and gloves during installation to prevent accidents. Moreover, understanding the load and stress tolerance of your particular application can prevent future complications. In conclusion, 3-inch concrete nails are a vital component for effective and lasting construction. Their unique design and application require a blend of experience, professional expertise, and attention to detail. By focusing on surface preparation, selecting the right tools, and following safety protocols, their use can be maximized across a myriad of construction tasks. Investing the time and resources to understand and implement these practices will undoubtedly enhance the quality and lifespan of the structures you build, anchoring your work not just in concrete, but in excellence.

The application of 3-inch concrete nails extends to numerous industry examples, bolstering their authoritative use. For instance, in carpentry, they're essential for framing in basements where wooden structures meet concrete floors or walls. In commercial construction, these nails help in the installation of rigid insulation panels or metal tracks, providing a basis for laying drywall. They are also prevalent in the mounting of fixtures and fittings where direct attachment to a concrete surface is required. Trustworthiness in using 3-inch concrete nails stems from their longstanding use in construction and their ability to meet standardized building codes. The nails provide a cost-effective solution with a proven track record, reinforcing their reliable choice among builders and contractors. Adopting best practices in the usage of concrete nails ensures not only the structural integrity of a project but also safety. It is critical to adhere to safety guidelines, such as using protective eyewear and gloves during installation to prevent accidents. Moreover, understanding the load and stress tolerance of your particular application can prevent future complications. In conclusion, 3-inch concrete nails are a vital component for effective and lasting construction. Their unique design and application require a blend of experience, professional expertise, and attention to detail. By focusing on surface preparation, selecting the right tools, and following safety protocols, their use can be maximized across a myriad of construction tasks. Investing the time and resources to understand and implement these practices will undoubtedly enhance the quality and lifespan of the structures you build, anchoring your work not just in concrete, but in excellence.

Share

Next:

Latest news

-

Types and Uses of Common Nails in Construction

NewsJul.31,2025

-

The Transformative Role of Square Wire Mesh in Contemporary Architecture

NewsJul.31,2025

-

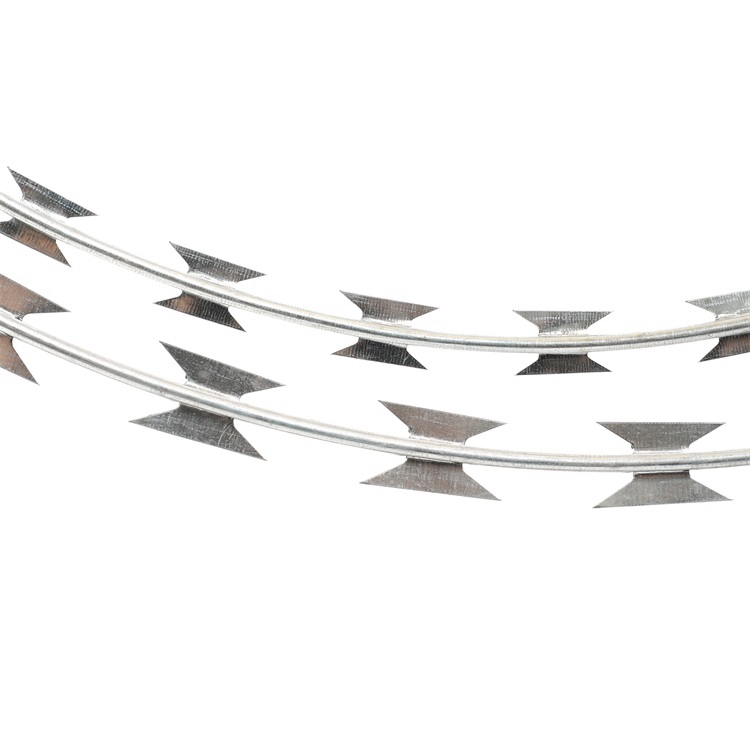

The Essential Role of Razor Wire in Modern Perimeter Security

NewsJul.31,2025

-

Installation Guide for Hexagonal Wire Netting Fencing

NewsJul.31,2025

-

How to Properly Use Rebar Wire Ties for Stronger Concrete Structures

NewsJul.31,2025

-

Creative and Decorative Uses of Barbed Wire in Design

NewsJul.31,2025