M36 Anchor Bolt Production and Sourcing Solutions for Industrial Applications

The Importance of High-Quality M36 Anchor Bolts A Spotlight on Manufacturers

Anchor bolts are critical components in the construction and engineering industries, providing the necessary support for various structures and facilitating the secure attachment of structural elements to concrete. Among the different sizes and types, M36 anchor bolts stand out due to their robust specifications and versatility. This article delves into the significance of M36 anchor bolts and offers insights into what to consider when choosing a manufacturer for these essential fasteners.

What Are M36 Anchor Bolts?

M36 anchor bolts refer to bolts with a diameter of 36 millimeters. These bolts are typically made of high-strength materials, capable of withstanding significant loads and forces. They are used in various applications, including securing machinery, stabilizing columns, and anchoring frameworks to foundations. The reliability and durability offered by M36 anchor bolts make them indispensable in projects ranging from commercial buildings to industrial facilities.

Choosing a Manufacturer Key Considerations

When it comes to selecting a manufacturer for M36 anchor bolts, several factors are paramount to ensure quality and reliability.

1. Quality Standards The manufacturer should adhere to international quality standards such as ISO 9001. Compliance with these standards guarantees that the products are manufactured with high-quality materials and processes. It is advisable to request documentation that certifies the manufacturer’s adherence to these standards.

2. Material Specifications M36 anchor bolts can be made from various materials, including carbon steel, stainless steel, and alloy steel. The choice of material significantly impacts the strength, corrosion resistance, and overall performance of the bolts. Ensure that the manufacturer provides specifications on the materials used and their respective mechanical properties.

3. Production Capabilities Assess the manufacturer’s production capabilities. A reputable manufacturer should be capable of producing M36 anchor bolts in large quantities while maintaining high-quality standards. They should also be equipped to handle custom orders to meet specific project requirements.

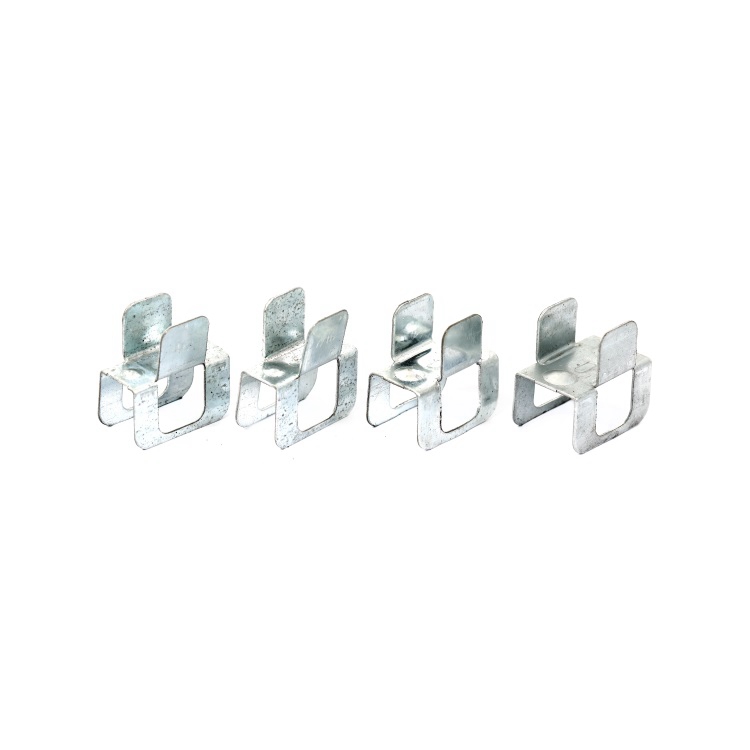

anchor bolt m36 manufacturer

4. Testing and Certification Manufacturers should implement rigorous testing procedures to validate the strength and durability of their anchor bolts. Third-party certifications and test reports can provide additional assurance of product quality. Inquire about their testing methodologies, including tensile strength tests and corrosion resistance evaluations.

5. Experience and Reputation A manufacturer's experience in producing anchor bolts can be a strong indicator of their reliability. Research the company’s history, customer testimonials, and project references. A well-established manufacturer with a solid reputation is more likely to provide high-quality products and superior customer service.

6. Lead Times and Delivery Timely delivery is crucial in construction projects. Discuss lead times with the manufacturer and ensure they can meet your project deadlines. Flexibility in production and shipping can be advantageous, particularly for large-scale projects.

7. Cost-Effectiveness While quality should never be compromised, it is also essential to consider the cost. Request quotes from multiple manufacturers to compare pricing. Evaluate whether the prices reflect the quality of the materials and workmanship. Beware of unusually low prices, as they may indicate inferior quality.

The Role of Innovation in Manufacturing

In recent years, technological advancements have transformed the manufacturing process for anchor bolts. Innovative techniques, such as precision forging and automated quality control systems, have enhanced the strength and performance of bolts while reducing production costs. Manufacturers that invest in modern technology are often better positioned to provide high-quality, cost-effective solutions.

Conclusion

M36 anchor bolts play a critical role in ensuring the structural integrity of various projects. Selecting the right manufacturer is essential to guarantee that these components meet the necessary standards for quality, durability, and performance. By considering factors such as quality standards, material specifications, production capabilities, and reputation, construction professionals can make informed decisions that align with their project needs. Investing time in selecting a reliable manufacturer will ultimately contribute to the success and longevity of any construction endeavor.

-

The Durability and Versatility of Steel Wire

NewsJun.26,2025

-

The Best Iron Nails for Your Construction Projects

NewsJun.26,2025

-

Strengthen Your Projects with Durable Metal Stakes

NewsJun.26,2025

-

Get the Job Done Right with Duplex Nails

NewsJun.26,2025

-

Explore the Versatility and Strength of Metal Mesh

NewsJun.26,2025

-

Enhance Your Security with Razor Wire

NewsJun.26,2025