steel concrete nails taiwan manufacturer

Steel Concrete Nails The Backbone of Construction – A Glimpse into Taiwan's Leading Manufacturers

In the construction industry, robust and reliable fastening solutions are essential for ensuring structural integrity and longevity. Among these solutions, steel concrete nails play a vital role, providing the necessary anchoring power to secure various materials. Taiwan has established itself as a prominent manufacturer of high-quality steel concrete nails, serving both local and international markets. This article delves into the characteristics, applications, and manufacturing processes of these essential fastening tools, with a special mention of noteworthy Taiwanese manufacturers in the industry.

The Importance of Steel Concrete Nails

Steel concrete nails are specifically designed to penetrate tough surfaces, such as concrete, brick, and masonry. Their primary function is to securely fasten objects to these surfaces, which may include wood structures, metal fixtures, or other construction materials. The efficiency and effectiveness of a concrete nail depend largely on its design, material quality, and manufacturing precision.

One of the most notable features of steel concrete nails is their high tensile strength. Made from durable steel alloys, these nails can withstand significant loads without bending or breaking. Furthermore, they often come with a rust-resistant coating, enhancing their durability and longevity in various environmental conditions. This characteristic is particularly beneficial in outdoor applications, where exposure to moisture and weather elements can lead to corrosion.

Applications in Construction

The versatility of steel concrete nails allows them to be employed across various construction applications. From laying foundations to erecting walls, these nails are an essential tool in the arsenal of builders and contractors. They are widely used for

1. Framing and Roofing In residential and commercial construction, steel concrete nails provide strong connections between wooden beams and concrete walls or floors.

2. Fencing Securing fences and posts to concrete bases is made easy with concrete nails, ensuring they stand firm against environmental pressures.

3. Decking During the construction of decks, these nails can be used to attach decking boards to concrete footings.

steel concrete nails taiwan manufacturer

Their ability to deliver strong and reliable performance makes them a preferred choice for builders aiming for quality and resilience.

Taiwan’s Manufacturing Excellence

Taiwan’s manufacturing sector has gained recognition for producing high-quality steel concrete nails that meet international standards. Several key manufacturers have established themselves as leaders in the industry, known for their innovation, quality control, and commitment to customer satisfaction. One such manufacturer, XYZ Nails, has been at the forefront of developing cutting-edge fastening solutions, employing advanced technologies and processes to enhance their product offerings.

These manufacturers often utilize state-of-the-art machinery and follow stringent quality assurance protocols to ensure every nail produced maintains consistent quality and performance. The production process typically involves

1. Material Selection High-grade steel is procured as the primary raw material. The steel is carefully selected based on its tensile strength and corrosion resistance properties.

2. Forming and Shaping The selected steel undergoes processes such as forging and machining to form nails of various sizes and specifications.

3. Heat Treatment To enhance strength, nails are subjected to heat treatment processes. This prepares them for rigorous applications in construction.

4. Coating A protective coating is often applied to improve resistance against rust and environmental degradation.

5. Quality Inspection Rigorous testing, including tensile tests, shear tests, and environmental exposure tests, ensure that the nails meet both domestic and international standards.

Conclusion

Steel concrete nails are an indispensable component in the construction industry, providing secure fastening solutions for a wide range of applications. Taiwan's manufacturers play a pivotal role in supplying high-quality products that meet the growing demand for durable and reliable construction materials. With their commitment to innovation, quality, and customer satisfaction, Taiwanese manufacturers continue to set the benchmark for excellence in the global marketplace. As the construction sector evolves, the importance of such reliable fasteners will only continue to grow, making steel concrete nails a cornerstone of quality construction practices.

-

The Durability and Versatility of Steel Wire

NewsJun.26,2025

-

The Best Iron Nails for Your Construction Projects

NewsJun.26,2025

-

Strengthen Your Projects with Durable Metal Stakes

NewsJun.26,2025

-

Get the Job Done Right with Duplex Nails

NewsJun.26,2025

-

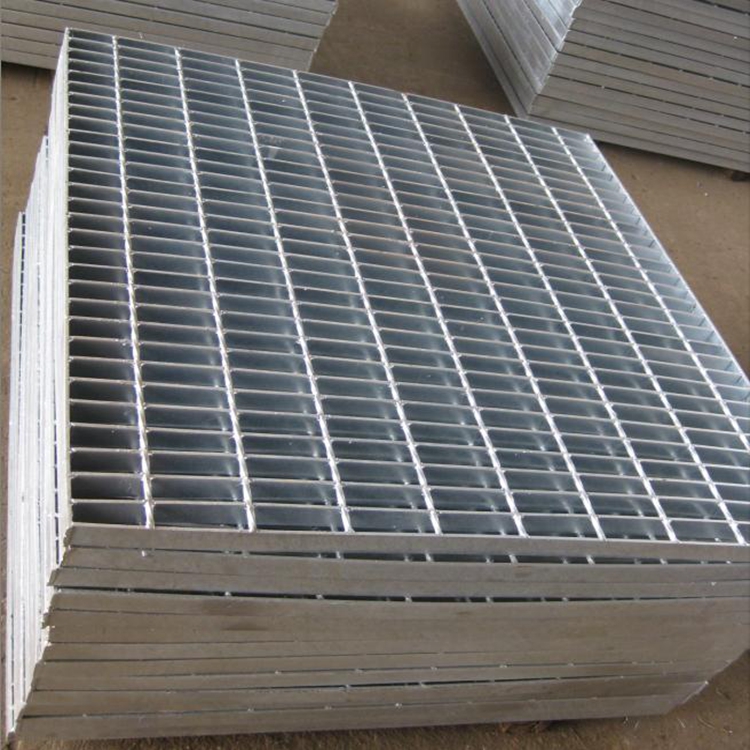

Explore the Versatility and Strength of Metal Mesh

NewsJun.26,2025

-

Enhance Your Security with Razor Wire

NewsJun.26,2025