Steel Specifications for Manufacturing Standard Common Nails in Factories

The Role of Steel in Common Nail Manufacturing

Nails, though often overlooked, play a crucial role in construction and manufacturing. Among the various types of nails, common nails are essential for a wide range of applications, from framing to general woodworking. The primary material used in the production of these nails is steel, which offers several advantages in terms of strength, durability, and cost-effectiveness. This article will delve into the significance of steel in common nail factories, exploring its properties, manufacturing processes, and the factors affecting nail quality.

The Importance of Steel

Steel is an alloy primarily composed of iron mixed with carbon and other elements, which give it its strength and versatility. In the context of nail manufacturing, the properties of steel make it the preferred material. The strength of steel allows common nails to hold materials together securely, while its malleability ensures that nails can be easily shaped during the manufacturing process.

Additionally, steel nails offer excellent resistance to bending and breaking, which is crucial in construction applications where structural integrity is paramount. Galvanization, a process where nails are coated with zinc, is often applied to steel nails to enhance their corrosion resistance. This is vital in outdoor applications where moisture and weather conditions can lead to rusting.

Manufacturing Processes

The manufacturing process of common nails begins with the selection of raw materials. Steel wire rods are the primary input used in nail production. These rods are sourced from steel mills, where they are produced through modern methods such as electric arc furnace (EAF) steelmaking or basic oxygen furnaces (BOF). Once the steel rods are obtained, they undergo several processing stages.

1. Wire Drawing The steel rods are drawn through a series of dies to reduce their diameter and create wire of the desired gauge. This step is critical as the size of the wire directly impacts the strength and function of the finished nails.

2. Cutting and Shaping The drawn wire is then cut into specific lengths, depending on the size of the nails being manufactured. The ends of the cut wire are pointed, usually through a process called nail making, which involves mechanical machines that shape the wire into the typical nail form.

steel for common nail factories

3. Heat Treatment To enhance the strength and durability of nails, some manufacturers implement heat treatment processes. This can involve quenching and tempering, which alters the physical properties of the steel, making the nails more resilient.

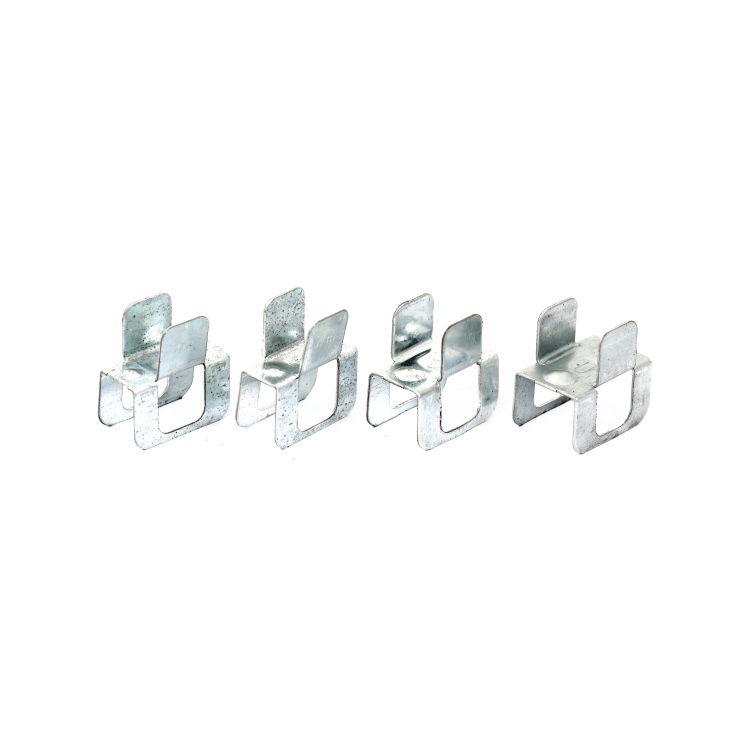

4. Galvanizing In many cases, nails are galvanized to protect against rust. The nails are immersed in molten zinc, creating a protective layer that significantly extends their lifespan, especially in outdoor environments.

5. Quality Control Before packaging, nails undergo rigorous quality control measures to ensure they meet industry standards. This includes tests for tensile strength, corrosion resistance, and overall finish.

Quality Factors

Several factors can influence the quality of common nails produced in factories. The type of steel used is paramount; higher-grade steel results in stronger and more reliable nails. Additionally, the precision in wire drawing, cutting, and shaping impacts the final product's performance. Manufacturers must also adhere to international standards, such as ASTM standards, to ensure their nails are suitable for various applications.

Another factor is the technological capability of the manufacturing facility. Factories equipped with advanced machinery can produce nails more efficiently and with greater precision. Automation in the manufacturing process not only increases output but also enhances the uniformity and quality of the nails produced.

Conclusion

In conclusion, steel is the backbone of common nail manufacturing, providing the necessary strength, durability, and cost-effectiveness that modern construction demands. The meticulous processes involved in transforming raw steel into quality nails highlight the significance of this material in the industry. As technology advances, steel production and nail manufacturing will continue to evolve, leading to even better products that meet the rigorous demands of construction professionals and DIY enthusiasts alike. Steel’s role in nail production is a testament to its adaptability and essential nature in the world of manufacturing.

-

The Durability and Versatility of Steel Wire

NewsJun.26,2025

-

The Best Iron Nails for Your Construction Projects

NewsJun.26,2025

-

Strengthen Your Projects with Durable Metal Stakes

NewsJun.26,2025

-

Get the Job Done Right with Duplex Nails

NewsJun.26,2025

-

Explore the Versatility and Strength of Metal Mesh

NewsJun.26,2025

-

Enhance Your Security with Razor Wire

NewsJun.26,2025