Hot Dipped Galvanized Steel Wire-Five Star Metals|Corrosion Resistance&Industrial Durability

Hot Dipped Galvanized Steel Wire: Durable Solution for Industrial Applications

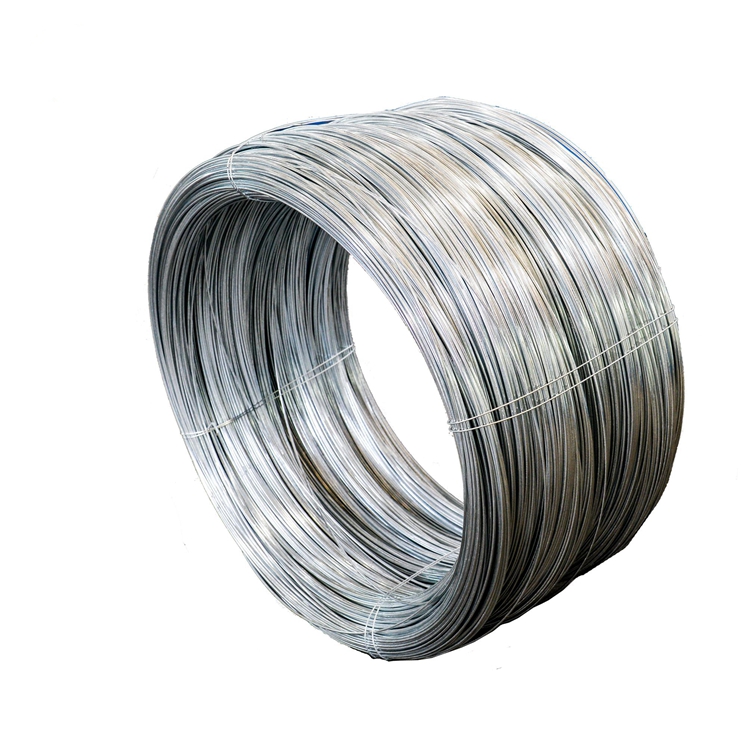

For industries requiring reliable and long-lasting materials, Hot Dipped Galvanized Steel Wire offers an exceptional combination of strength, corrosion resistance, and versatility. Manufactured by Five Star Metals, this product is engineered to meet the demanding requirements of modern industrial applications.

Product Overview and Core Features

Hot Dipped Galvanized Steel Wire is produced through a specialized process where steel wire is submerged in molten zinc to create a protective coating. This method ensures superior corrosion resistance, making it ideal for outdoor and harsh environments. The product is available in various diameters and grades, tailored to meet specific industrial needs.

Industrial Applications and Market Demand

With its robust properties, Hot Dipped Galvanized Steel Wire is widely used in construction, agriculture, automotive, and infrastructure projects. Its ability to withstand extreme weather conditions and mechanical stress makes it a preferred choice for applications such as fencing, reinforcing structures, and electrical grounding systems. The growing demand for durable materials in these sectors highlights the product's relevance in today's market.

Company Expertise and Technological Advancements

As a leading supplier in the metal industry, Five Star Metals leverages advanced manufacturing technologies to ensure consistent quality and performance. The company's commitment to innovation and customer-centric solutions has established it as a trusted partner for businesses seeking reliable steel products.

Performance and Customer Testimonials

Users of Hot Dipped Galvanized Steel Wire report significant improvements in project longevity and cost efficiency. For instance, a construction firm in Texas noted a 40% reduction in maintenance costs after switching to this product. Such testimonials underscore its value in real-world applications.

Usage Guidelines and Customization Options

To maximize the benefits of Hot Dipped Galvanized Steel Wire, it is recommended to follow specific installation and handling protocols. Five Star Metals offers customized solutions, including tailored specifications and bulk ordering options, to suit diverse operational requirements.

Safety and Compliance

The product adheres to international safety standards, ensuring environmental and user safety. Its zinc coating is non-toxic and recyclable, aligning with global sustainability goals.

Packaging and Logistics

Designed for industrial-scale procurement, the steel wire is packaged in durable crates to prevent damage during transit. Five Star Metals provides efficient shipping solutions to ensure timely delivery worldwide.

Support and After-Sales Services

Customers receive comprehensive technical support, including application guidance and troubleshooting. The company also offers flexible return policies and product guarantees to ensure satisfaction.

Contact and Further Information

For detailed specifications or to place an order, visit the Hot Dipped Galvanized Steel Wire page or contact Five Star Metals directly via phone or email.

Conclusion

Hot Dipped Galvanized Steel Wire from Five Star Metals delivers unmatched durability and value. Explore our solutions today to enhance your project's efficiency and sustainability.

Frequently Asked Questions (FAQ)

Q1: What is the typical lifespan of hot-dipped galvanized steel wire?

A: Under normal conditions, the coating can last 50+ years, depending on environmental factors.

Q2: Can the wire be customized for specific projects?

A: Yes, we offer tailored specifications to meet unique application requirements.

Q3: Is the product environmentally friendly?

A: The zinc coating is non-toxic and fully recyclable, complying with global environmental standards.

-

Transform Your Outdoor Spaces with High-Quality Gabions

NewsJul.23,2025

-

The Power and Versatility of Wire Mesh for Your Projects

NewsJul.23,2025

-

The Complete Guide to Annealed Wire

NewsJul.23,2025

-

Pallet Nails--The Essential Fastener for Pallet Construction

NewsJul.23,2025

-

Anchor Bolt Analysis: A Key Component to Ensure Building Stability

NewsJul.23,2025

-

Enhance Your Property Security with Quality Barbed Wire

NewsJul.23,2025