grade 8.8 bolt specification manufacturers

Understanding Grade 8.8 Bolt Specifications and Manufacturers

When it comes to fasteners, grade identification plays a crucial role in determining the strength and suitability of bolts for various applications. One of the most commonly used grades in heavy-duty applications is Grade 8.8, which has garnered attention in industries ranging from automotive to construction. Understanding the specifications and manufacturers of Grade 8.8 bolts is essential for professionals seeking reliability and safety in their projects.

Grade 8.8 bolts are made of medium carbon steel that has been quenched and tempered, providing a good balance of strength and ductility. The 8 in the designation signifies a minimum yield strength of 640 MPa, while the second 8 indicates a minimum tensile strength of 800 MPa. This makes Grade 8.8 bolts suitable for use in high-stress environments, where mechanical stability is paramount.

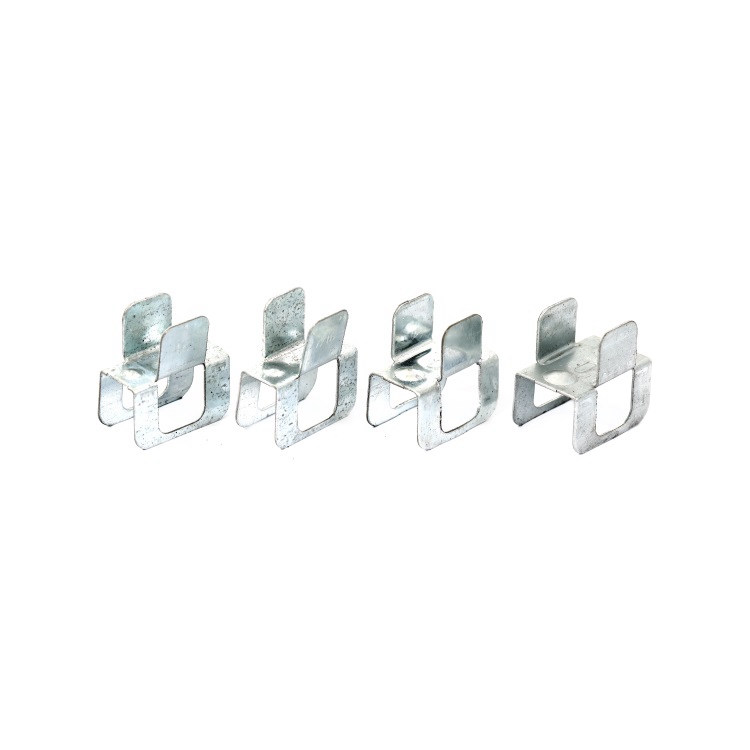

One of the key specifications for Grade 8.8 bolts includes their hardness, typically rated at a hardness range of 10 to 22 HRC (Rockwell Hardness Scale). This level of hardness contributes to their wear resistance and overall durability. Additionally, these bolts are often coated with zinc to prevent corrosion, which is critical for applications exposed to harsh environments.

grade 8.8 bolt specification manufacturers

Manufacturers of Grade 8.8 bolts adhere to strict international standards, such as those set by the International Organization for Standardization (ISO) and the European Committee for Standardization (CEN). The ISO 898-1 standard delineates the mechanical properties of bolts, helping to ensure that they meet the requisite performance criteria across different scenarios.

Some of the notable manufacturers producing Grade 8.8 bolts include companies like Fastenal, Bolt Products, and Würth Group. These manufacturers utilize advanced manufacturing processes, including computer numerical control (CNC) machining, to ensure dimensional accuracy and consistency in their products. They also conduct rigorous testing to validate the mechanical properties of their bolts, ensuring compliance with industry standards.

When selecting Grade 8.8 bolts, it is crucial to consider not only the specifications but also the reputation of the manufacturer. Quality assurance processes that include material inspection, tensile testing, and surface treatment validation are essential factors that can influence the performance of the bolts in real-world applications.

In essence, Grade 8.8 bolts provide a reliable fastening solution for demanding applications. By understanding the specifications and carefully choosing manufacturers that prioritize quality, professionals can ensure that they are using the best possible components for their projects. Whether for structural applications in construction or automotive assembly, Grade 8.8 bolts stand out as a top choice for those seeking strength, durability, and reliability.

-

The Versatility of Gabion Mesh

NewsMay.09,2025

-

The Versatility and Durability of Square Wire Mesh

NewsMay.09,2025

-

The Importance of a Quality Border Fence

NewsMay.09,2025

-

Hexagonal Wire Netting: A Complete Guide to Its Versatility and Value

NewsMay.09,2025

-

Explore the Benefits of Bulk Field Fence

NewsMay.09,2025

-

Discover Quality Weld Mesh for All Your Needs

NewsMay.09,2025