Navigating the Market: Current Trends for Industrial Fasteners

The global industrial fasteners market, valued at over USD 85 billion, is projected to grow consistently, driven by robust construction and manufacturing sectors. Today's market demands more than just a low price; it requires a blend of cost-effectiveness, superior material quality, and supply chain reliability. There's a significant shift towards products offering enhanced durability and corrosion resistance, like hot-dip galvanized fasteners, to reduce long-term maintenance costs. For procurement managers and project engineers, finding a source for discount 16 d common nails that doesn't compromise on quality is paramount. This trend extends to related products, where demand for specialized items like `oem welded wire mesh for underground mines` and `oem retaining walls gabion` is increasing, reflecting a need for tailored, high-performance solutions for specific environmental challenges.

Technical Specifications: Discount 16 D Common Nails at a Glance

Understanding the technical DNA of a 16d common nail is crucial for ensuring it meets project requirements. The "d" is a historical denotation for "penny," indicating nail length. A 16d common nail is standardized at 3.5 inches. Below is a comprehensive specification table that adheres to industry standards like ASTM F1667, ensuring you receive a product built for performance and reliability.

| Parameter |

Specification |

Importance & Industry Relevance |

| Nail Type |

16d Common Nail |

Standardized designation for heavy-duty framing and construction. |

| Length (L) |

3.5 inches (88.9 mm) |

Ideal length for joining 2x lumber (e.g., 2x4s, 2x6s). |

| Shank Diameter |

0.162 inches (4.11 mm / 8 Gauge) |

Provides excellent shear strength and holding power, critical for structural integrity. |

| Head Diameter |

~0.344 inches (8.7 mm) |

A wide, flat head prevents pull-through and distributes load effectively. |

| Material |

Low-Carbon Steel (Q195, Q235) |

Offers a balance of ductility for manufacturing and strength for application. Conforms to ISO 9001 quality standards. |

| Coating Options |

Bright Finish, Electro-Galvanized (EG), Hot-Dip Galvanized (HDG) |

Bright is for interior use. HDG offers superior corrosion resistance (ASTM A153) for exterior or treated lumber applications. |

| Approx. Nails per Pound |

~45-50 |

Essential data for project estimation and cost calculation. |

| Tensile Strength |

>75,000 PSI |

Indicates the nail's resistance to being pulled apart, a key measure of quality. |

| Compliance Standard |

ASTM F1667, ANSI/ASME B18.2.1 |

Ensures dimensional accuracy, material quality, and performance consistency. |

The Manufacturing Journey: From Raw Steel to a Perfect Nail

The production of a seemingly simple product like a discount 16 d common nails involves a precise, multi-stage engineering process governed by strict quality controls. Our commitment to excellence, certified by ISO 9001, ensures every nail meets or exceeds industry specifications. Here’s a detailed look at our manufacturing workflow:

🔩

1. Raw Material Selection

We start with high-grade Q195 or Q235 low-carbon steel wire rods, selected for their optimal tensile strength and formability.

→

🔄

2. Wire Drawing

The raw rods are pulled through a series of dies to reduce their diameter to the precise 0.162 inches required for a 16d nail.

→

🔨

3. Nail Heading & Pointing

The drawn wire is fed into an automated nail-making machine. In a high-speed process, a hammer forges the head, and cutters form the sharp diamond point.

→

✨

4. Polishing / Coating

Nails are tumbled to remove burrs. For enhanced durability, they undergo galvanization (Hot-Dip or Electro) for superior corrosion resistance.

→

🔬

5. Quality Control & Packaging

Samples from each batch are tested for dimensional accuracy, tensile strength, and coating thickness (per ASTM A153/B633). Approved nails are then packaged to client specifications.

This meticulous process guarantees that whether you order standard nails or a custom `oem binding wire black annealed`, the quality remains consistently high. Our expertise extends to a wide range of wire products, including `oem square wire welded mesh` and `discount double twist hexagonal mesh netting`, all produced with similar attention to detail.

Technical Advantages & Manufacturer Comparison

Choosing the right supplier for your industrial fasteners goes beyond the initial price. It's about securing long-term value. Our products, from discount 16 d common nails to specialized fencing, offer distinct advantages rooted in superior materials and manufacturing excellence. We also provide specialized tools like the `discount tools manufacturer tie tool` to improve installation efficiency on-site.

Superior Material Strength

- High-Tensile Steel: Our nails resist bending during driving, reducing waste and labor time.

- Consistent Hardness: Ensures reliable performance in various wood types, from soft pine to dense hardwoods.

- Structural Integrity: The high shear strength is critical for load-bearing applications in framing and construction.

Advanced Corrosion Resistance

- Hot-Dip Galvanization (HDG): A thick, metallurgical-bonded zinc coating provides decades of protection, ideal for outdoor use and treated lumber.

- Electro-Galvanization (EG): A smooth, thinner zinc coating suitable for interior applications where some moisture resistance is needed.

- Compliance with ASTM A153: Guarantees the quality and thickness of the protective zinc layer.

Precision Engineering

- Sharp Diamond Point: Ensures easy driving and minimizes wood splitting.

- Well-Formed Heads: Provides a large striking surface and excellent holding power.

- Strict Dimensional Tolerances: Guarantees compatibility with pneumatic nail guns and consistent quality.

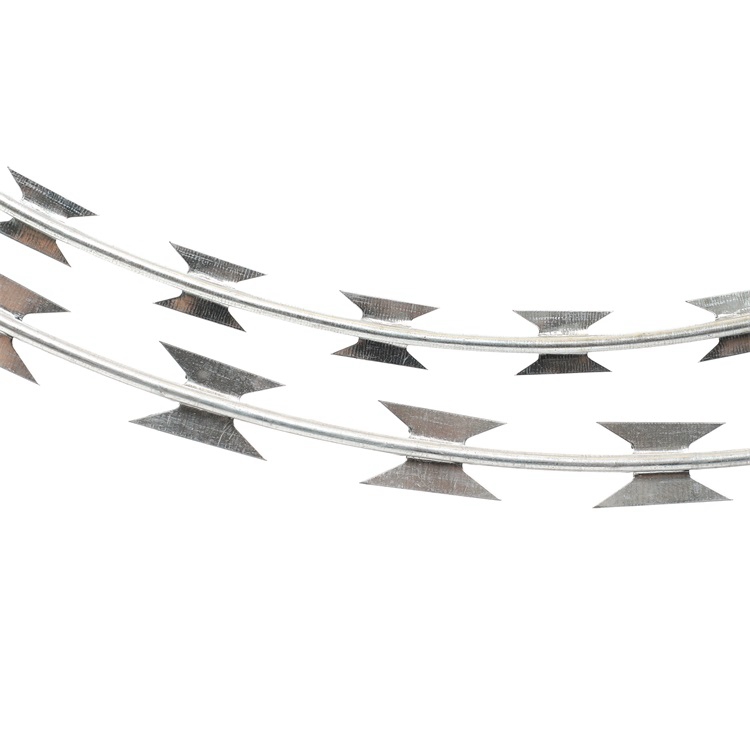

Featured Product: Galvanized Razor Barbed Wire Fence

For applications demanding the highest level of security, our Galvanized Razor Barbed Wire Fence is the definitive solution. Often used in conjunction with `oem welded wire mesh fence panels in 12 gauge`, it creates an imposing physical barrier. Manufactured from high-tensile steel and heavily galvanized, it offers extreme durability and deterrence against intrusion.

Key Features: Concertina coils, sharp blades, high tensile strength, and superior corrosion resistance make it ideal for protecting industrial sites, airports, and critical infrastructure.

View Product Details

Data-Driven Insights: Visualizing Product Performance

Data provides clarity. To demonstrate the superior quality of our products, we present a series of charts analyzing key performance indicators for our Galvanized Razor Barbed Wire Fence, a product that exemplifies our commitment to durability and quality manufacturing.

Corrosion Resistance Comparison (Service Life)

Market Application Share

Retained Tensile Strength Over Time (Simulated Exposure)

Customization and OEM Solutions: Your Vision, Our Expertise

We understand that standard products don't always fit unique project requirements. As a leading OEM/ODM partner, we specialize in creating custom solutions. Whether you need a specific coating for your discount 16 d common nails, unique dimensions for `oem square wire welded mesh`, or specially designed `oem plastic mushroom rebar cap` for enhanced safety, our engineering team is ready to collaborate.

Our OEM Capabilities Include:

- Material Specification: Choice of steel grades, stainless steel, or other alloys.

- Custom Dimensions: Specific lengths, diameters, and head styles for nails and wire products.

- Surface Treatments: Custom colors, specialized anti-corrosion coatings, and unique finishes. For instance, we produce `oem binding wire black annealed` for specific aesthetic and functional needs in the construction and crafting industries.

- Safety Products: We offer `oem cap mushroom` and rebar caps to prevent job-site injuries, a testament to our focus on comprehensive solutions.

- Packaging & Labeling: Custom branding, bulk packaging, or retail-ready boxes with your company's logo and information.

Application Case Study: Securing an Industrial Logistics Park

Client: A leading developer of industrial logistics parks.

Challenge: The client required a comprehensive and cost-effective solution to construct structural frames for several large warehouses and secure the entire 50-acre perimeter. The solution needed to be durable, quick to install, and able to withstand harsh weather conditions.

Our Solution: We devised a multi-product strategy:

- Structural Framing: We supplied over 5 tons of our hot-dip galvanized discount 16 d common nails. The HDG coating was crucial for use with pressure-treated lumber, preventing premature corrosion and ensuring the longevity of the structures.

- Perimeter Fencing: A 10-foot high fence was constructed using our `oem welded wire mesh fence panels in 12 gauge` for the primary barrier. This provided a strong and visually clear boundary.

- High-Security Topping: To deter climbing, our Galvanized Razor Barbed Wire Fence was installed atop the mesh fence.

- Landscaping & Safety: For erosion control on sloped areas, `oem retaining walls gabion` were deployed. Throughout the construction site, our bright `oem plastic mushroom rebar cap` was used on exposed rebar, significantly enhancing worker safety and complying with OSHA standards.

Outcome: The client completed the project ahead of schedule and under budget. They reported a 15% reduction in material waste due to the high quality of the nails (minimal bending) and the efficiency of the fencing system. The integrated solution from a single, reliable supplier streamlined their procurement process and ensured component compatibility. The client's project manager stated, "The quality and reliability of the materials, from the nails to the razor wire, were exceptional. Partnering with a manufacturer who understands the full scope of a project's needs was a game-changer for us."

Frequently Asked Questions (FAQ)

1. What does "16d" mean, and why is it important for discount 16 d common nails?

The "d" is the symbol for "penny," a traditional system for sizing nails originating from England. A 16d nail is consistently 3.5 inches long. This standardization is critical for builders and engineers because it directly corresponds to building codes and best practices for specific applications, such as framing with 2x lumber. Using the correct size ensures the structure has the required shear and withdrawal strength.

2. When should I choose Hot-Dip Galvanized (HDG) over Bright Finish nails?

You should always choose Hot-Dip Galvanized (HDG) nails for exterior applications, for use with pressure-treated lumber (which is highly corrosive), or in any environment with high moisture. HDG nails have a thick, protective zinc coating that is metallurgically bonded to the steel, offering superior, long-lasting corrosion protection (conforming to ASTM A153). Bright finish nails have no protective coating and will rust quickly when exposed to the elements; they are only suitable for dry, interior applications.

3. What is the advantage of your `oem welded wire mesh fence panels in 12 gauge`?

Our 12-gauge welded wire mesh panels offer an excellent balance of strength, visibility, and cost. The 12-gauge wire is thick enough to be rigid and difficult to cut with standard tools. The welding at each intersection creates a strong, uniform grid that resists sagging. As an OEM product, we can customize the panel size, mesh opening, and finish (e.g., galvanized or PVC coated) to meet specific security and aesthetic requirements.

4. How do `oem retaining walls gabion` work for erosion control?

Gabions are wire mesh baskets (typically `discount double twist hexagonal mesh netting` for flexibility) filled with rocks or other inorganic material. When stacked, they form a massive, permeable structure. This permeability allows water to drain through, preventing hydrostatic pressure buildup that can destroy solid walls. The mass of the rocks provides the force to hold back soil, making them an extremely effective and eco-friendly solution for stabilizing slopes and preventing erosion.

5. What quality standards do your products adhere to?

Our manufacturing facilities are ISO 9001:2015 certified, which means we follow a strict quality management system. Our products are manufactured to meet or exceed relevant international standards. For example, our nails conform to ASTM F1667 for dimensional and material standards, and our galvanization process adheres to ASTM A153 (for hot-dip) or ASTM B633 (for electro-galvanization). This commitment to standards ensures you receive a product that is safe, reliable, and consistent.

6. Can you explain the purpose of an `oem plastic mushroom rebar cap`?

An OEM plastic mushroom rebar cap is a critical safety device used on construction sites. It is a brightly colored plastic cap placed over the exposed ends of steel reinforcing bars (rebar). Its primary purpose is to prevent impalement injuries, which can be severe or fatal if a worker falls onto an unprotected rebar. The "mushroom" shape provides a wider, blunter surface area. We offer them as an OEM product to ensure they fit various rebar diameters and meet site-specific color or branding requirements.

7. What is your typical delivery lead time and warranty?

Delivery lead times vary based on the product, quantity, and level of customization. For standard stock items like discount 16 d common nails, we can often ship within 7-10 business days. For large OEM orders, the lead time is typically 30-45 days. We provide a detailed delivery schedule upon order confirmation. All our products are backed by a comprehensive manufacturer's warranty against defects in materials and workmanship. Our galvanized products are warranted for their anti-corrosion performance under specified environmental conditions. Please contact our sales team for detailed warranty information on specific products.

Authoritative References & Further Reading

To ensure our content is aligned with the highest industry standards, we reference leading publications and standards bodies. For deeper technical understanding, we recommend the following resources:

- ASTM International (ASTM F1667): Standard Specification for Driven Fasteners: Nails, Spikes, and Staples. This is the core standard governing nail manufacturing in North America. View Standard on astm.org

- Journal of Construction and Building Materials: A peer-reviewed journal that often publishes research on fastener performance, corrosion, and structural integrity. A search for "fastener corrosion in treated wood" will yield relevant studies. Explore the Journal

- American Galvanizers Association (AGA): Provides extensive data and technical papers on the performance and lifespan of hot-dip galvanized steel in various environments. Visit galvanizeit.org