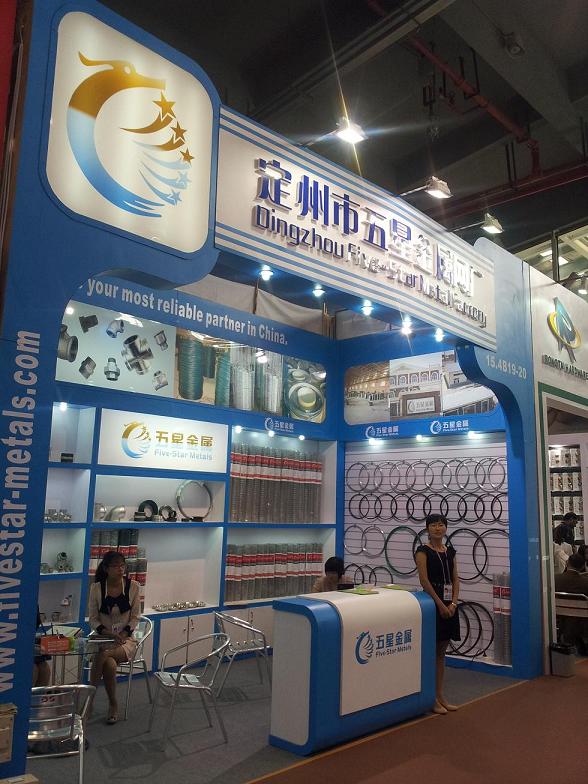

steel wire mesh manufacturer

Understanding Steel Wire Mesh A Versatile Solution for Various Industries

Steel wire mesh, a versatile and durable product, has gained significant popularity across various sectors due to its unique properties and wide range of applications. This article explores the characteristics of steel wire mesh, the manufacturing process, and the various industries that rely on it.

What is Steel Wire Mesh?

Steel wire mesh is a grid-like structure made from interwoven steel wires. Typically manufactured in sheets or rolls, it is available in a variety of sizes, shapes, and thicknesses. The steel used in wire mesh can be galvanized or stainless, which provides additional resistance to corrosion and enhances durability. The design of steel wire mesh allows it to meet specific loading requirements while maintaining structural integrity, making it a perfect choice for numerous applications.

Manufacturing Process

The process of manufacturing steel wire mesh involves several stages

1. Wire Production The first step is the production of steel wire. Raw steel is drawn into wire of various diameters, which can then be coated or treated depending on the desired characteristics, such as corrosion resistance.

2. Weaving or Welding The wires are then woven or welded together to create a mesh. Weaving involves interlacing the wires at regular intervals, while welding uses electric spot welding to join the wires at intersections, ensuring a robust structure.

4. Quality Control Lastly, rigorous quality control measures are implemented to ensure that the finished product meets industry standards.

Applications Across Industries

steel wire mesh manufacturer

Steel wire mesh is utilized across various sectors owing to its strength, flexibility, and ease of installation. Below are some of the primary industries that depend on steel wire mesh

1. Construction One of the predominant uses of steel wire mesh is in the construction industry. It is frequently used as reinforcement in concrete slabs, walls, and pavements, as it enhances tensile strength and provides stability. It is also used in fencing to secure construction sites or private properties.

2. Agriculture In the agricultural sector, steel wire mesh is employed for fencing, animal enclosures, and crop support structures. Its durability and weather resistance make it ideal for protecting crops from pests and animals.

3. Mining Steel wire mesh serves critical functions in the mining industry, particularly in screening and separating materials. It is used in various applications such as rock bolting and underground support systems to ensure safety and structural integrity.

4. Manufacturing In manufacturing, steel wire mesh is used for filtration and separation processes. The mesh can serve as a sieve to separate materials of different sizes, making it essential for processing industries.

5. Architectural Design An emerging application of steel wire mesh is in architectural design, where it is used as a decorative element in facades, partitions, and ceilings. Its versatility allows architects to create innovative designs while providing the functionality of security and structural support.

Advantages of Steel Wire Mesh

The advantages of steel wire mesh are numerous. It is cost-effective, durable, and can withstand harsh environmental conditions. Additionally, steel wire mesh is lightweight and easy to handle, which simplifies transportation and installation processes. Whether for structural support or decorative purposes, steel wire mesh offers an optimal solution that meets diverse needs.

Conclusion

In conclusion, steel wire mesh manufacturers play a crucial role in providing a product that is essential for various industries. With its unique properties, versatile applications, and robust manufacturing processes, steel wire mesh is an indispensable material in today’s world. As industries continue to evolve and innovate, the demand for high-quality steel wire mesh will remain strong, ensuring that this product continues to be a vital component in construction, agriculture, mining, manufacturing, and beyond. Whether you are a contractor, farmer, or architect, choosing the right steel wire mesh can significantly enhance the efficiency and longevity of your projects.

-

The Versatility of Gabion Mesh

NewsMay.09,2025

-

The Versatility and Durability of Square Wire Mesh

NewsMay.09,2025

-

The Importance of a Quality Border Fence

NewsMay.09,2025

-

Hexagonal Wire Netting: A Complete Guide to Its Versatility and Value

NewsMay.09,2025

-

Explore the Benefits of Bulk Field Fence

NewsMay.09,2025

-

Discover Quality Weld Mesh for All Your Needs

NewsMay.09,2025