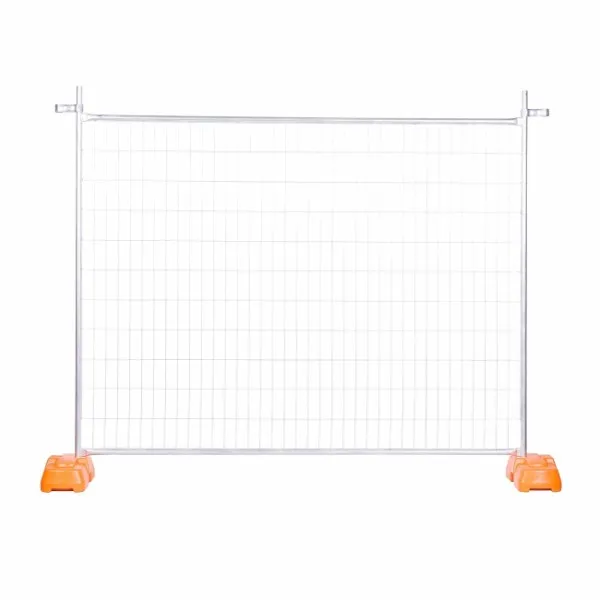

Heavy-Duty Welded Wire Mesh Temporary Fence | Security & Fast Install

Welded Wire Mesh Temporary Fence systems represent the state-of-the-art in modular site protection across civil engineering projects, infrastructure renovation, events, and industrial applications. Welded Wire Mesh Temporary Fence provides a highly flexible, reusable, and robust perimeter solution, meeting the latest international safety and performance standards. This guide delivers a deep-dive into welded mesh fencing: technology, manufacturing, parameters, comparative analysis, and real-world applications—supported by industry data and certified standards.

1. Industry Trends & Market Adoption of Welded Wire Mesh Temporary Fence

According to a 2023 market report by MarketsandMarkets™, the global temporary fencing market is projected to reach USD 4.3 billion by 2027, with welded mesh variants accounting for over 47% of total product adoption, due to their superior durability, fast deployment, and versatility (MarketsandMarkets).

- Construction & Infrastructure: 38% market usage share; driven by regulatory site enclosure requirements (OSHA, ISO 14122-3).

- Event Management: Rapid setup for concerts, public gatherings, sports — accounts for 22% of welded wire mesh fence applications.

- Industrial Facilities, Petrochemical, and Utility Sectors: Value the anti-corrosive, maintenance-free performance.

2. Technical Parameters & Specifications

Understanding essential technical parameters is critical for selecting the right Welded Wire Mesh Temporary Fence. Key terms include mesh aperture, wire gauge, coating type, and panel strength. Leading suppliers provide full compliance with ISO and ANSI standards, ensuring product consistency, mechanical integrity, and safety.

| Parameter | Standard Model | Enhanced Model | Custom (OEM) |

|---|---|---|---|

| Panel Size (WxH) | 2.1m x 2.4m | 2.2m x 2.8m | 1.8–3.0m x 2.0–3.0m |

| Wire Diameter | 3.0 mm | 4.0 mm | 2.8–5.0 mm |

| Mesh Aperture | 60 x 150 mm | 50 x 100 mm | As requested |

| Frame Tube | 32 mm OD x 1.5 mm | 42 mm OD x 2.0 mm | 32–60 mm OD x 1.5–2.5 mm |

| Coating | Hot-dip Galvanized (≥42 μm) | PVC/PE + HDG (≥60 μm) | Custom RAL Colors |

| ISO Standard | ISO 1461 | ISO 1461 / ISO 9227 | ANSI/ASTM/ISO/CSA |

| Lifetime | 5–8 years | 8–15 years | As specified |

| Wind/Impact Resistance | Class 4 / 800N | Class 5+ / 1200N | Up to 1800N |

3. Manufacturing Process Flow – Welded Wire Mesh Temporary Fence

The manufacturing process for Welded Wire Mesh Temporary Fence follows strict quality control per ISO 9001, emphasizing precision, anti-corrosion, and lifecycle performance. The typical workflow includes cold drawing, welding, framing, and surface treatment. Below is a schematic process flow:

3.1 Key Materials, Processing & Quality

- Steel Selection: Low-carbon Q195 or Q235 grades — optimal balance between weldability & strength.

- CNC Control: Precision mesh aperture & frame fit via CNC-welding robotics.

- Coating: 42–60μm zinc (HDG); optional powder/PVC finish for severe environments (ISO 12944, ASTM B117 corrosion test).

- Testing: Dimensional, weld tensile (≥800N), adhesion (ASTM D3359), and salt spray (> 500–1,000 hours).

4. Comparative Technical Performance: Welded vs. Chain Link Temporary Fence

| Index | Welded Wire Mesh Temporary Fence | Chain Link Temporary Fence |

|---|---|---|

| Coating Thickness | ≥42 μm (Hot-dip Galv.) | ≤25 μm (Electro Galv.) |

| Salt Spray Test (ISO 9227) | > 800 hours | 200–300 hours |

| Anti-Climb Mesh | Yes (≤75mm x 150mm) | No |

| Reusable Lifespan | 8–15 years (5–8 cycles) | 3–6 years (1–2 cycles) |

| Repairability | Weld patch, modular parts | Must replace netting |

| Compliance | ISO, ANSI, CSA, AS/NZS | ASTM, Some ISO |

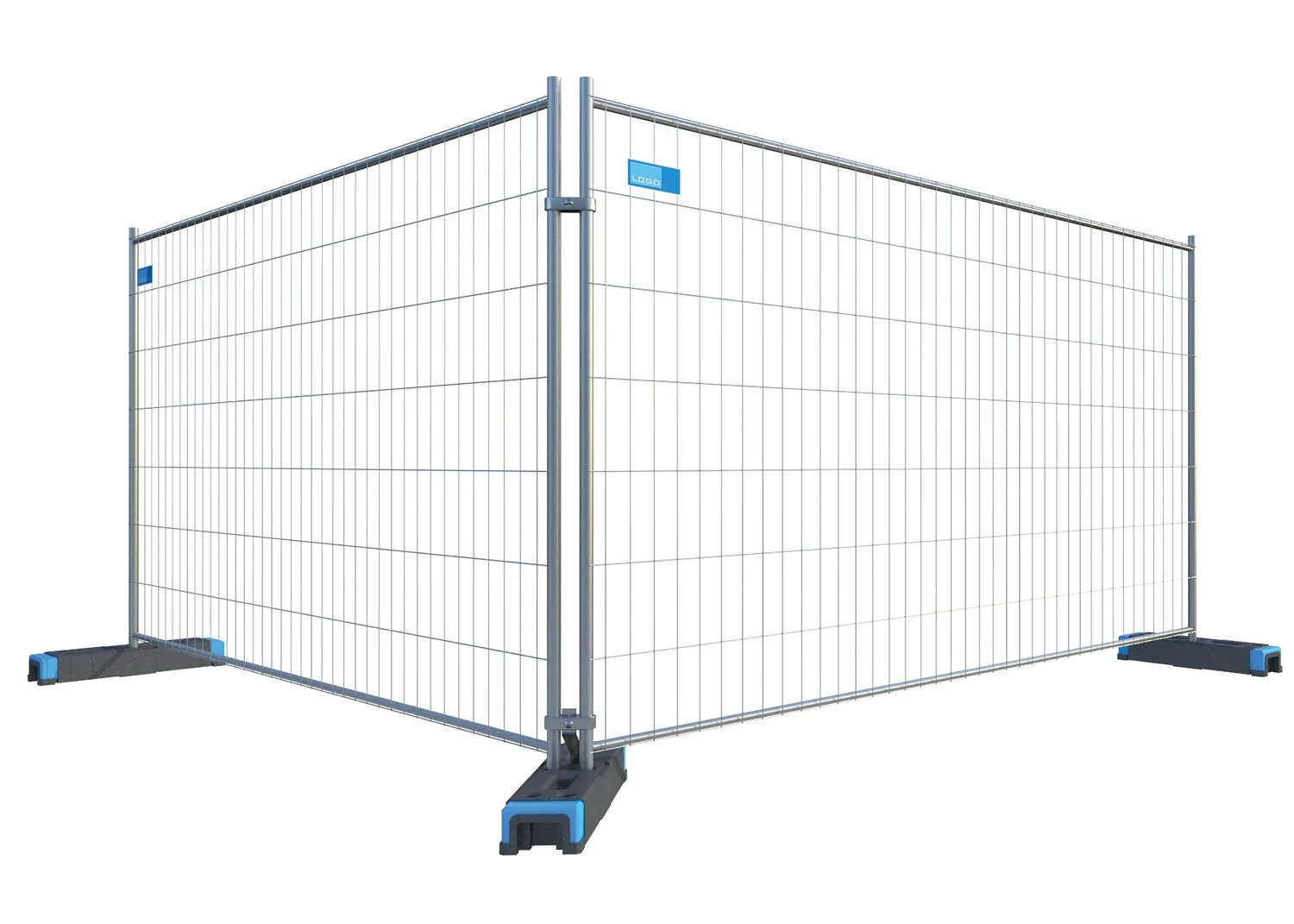

5. Application Scenarios & Custom Solutions

5.1 Typical Application Scenarios

- Construction Sites: Site safety perimeter, debris retention in high wind zones (meets OSHA/EN13374).

- Petrochemical Facilities: Corrosion-resistant boundary fencing in aggressive environments (ISO 9227 salt fog tested; lifespan >10 years).

- Public Events & Crowd Control: Fast modular deployment, anti-tipping solutions, branding panels.

- Metallurgy & Industrial Plants: Space partitioning, traffic segregation, machine safety cages.

- Municipal Utilities: Water works, electrical substations, restricted area security.

5.2 Customization Options

- Color Customization: Powder coated to any RAL color for event branding or safety visibility.

- Mesh Density: Anti-climb mesh formats (optional privacy slats, laser logo inserts).

- Panel Geometry: Custom heights (1.8–3.0m), frame tube thickness, and base bracket style for harsh terrains.

- Integrated Features: Lockable gates, signage mounts, stabilizers, wind bracing bars.

Contact our engineering team for a tailored Welded Wire Mesh Temporary Fence proposal, including project-specific wind load and anti-tamper testing.

6. Industry Certifications, Quality Control & After-Sales Standards

- ISO 9001:2015 (Quality Management), ISO 1461 (Hot-dip Galvanizing), ANSI, CSA, AS/NZS 4687:2007—they ensure product uniformity, safety, anti-corrosion, and international acceptance.

- Factory offers third-party inspection (SGS, BV), traceable batch production, and 100% panel/weld quality checks.

- Backed by a warranty of up to 5–10 years: full product replacement against manufacturing defects or rust-through.

Our Welded Wire Mesh Temporary Fence is trusted by leading contractors worldwide, extensively used in major government, infrastructure, and energy projects.

7. Application Case Studies & User Feedback

— Project Manager, Australian Tier-1 Contractor (2023), sourced from industry feedback

- Case 1: Singapore National Stadium Renovation — 4km of mesh fencing installed in 48 hours, featuring anti-climb mesh, lockable gates, and branded sign panels. Maintained corrosion-free finish after 3 monsoon seasons.

- Case 2: Energy Utility (Europe) — Deployed fence panels with added privacy screening; outperformed chain-link during 11-month salt spray field test by a factor of 3× in durability.

- Case 3: Covid-19 Quarantine Zones — Rapid mobile fence deployment, improved site security, zero report of unauthorized breach, verified by ISO 45001 auditing team.

8. Delivery, Warranty, Customer Support

- Lead Time: Standard panels ship in 7–14 days; custom orders in 22–28 days.

- Warranty: Up to 10 years anti-corrosion; free replacement for defects.

- Support: 24/7 technical assistance, on-site installation guides, video tutorials, and engineering drawings available.

All orders receive a technical datasheet, MTR, and installation/maintenance manual. Project reference lists and test reports are available upon request.

9. FAQ: Professional Technical Inquiries

- Q1: What base material is used for Welded Wire Mesh Temporary Fence? Why?

- A1: Low-carbon steel (Q195/Q235) is standard, providing high tensile strength and weldability. Optionally, stainless steel (AISI 304/316) available for aggressive chemical environments.

- Q2: What are the typical mesh opening sizes and how do they affect security?

- A2: Openings of 50x100mm and 60x150mm are most common. Smaller apertures prevent foothold, offering anti-climb capability for event and industrial applications.

- Q3: What coating standards ensure anti-corrosion performance?

- A3: Hot-dip galvanizing per ISO 1461 and salt spray testing per ISO 9227 guarantee ≥8–10 years corrosion resistance under typical outdoor exposure.

- Q4: How is the fence installed and anchored for stability (e.g., wind loads)?

- A4: Modular panels connect via steel clamps; baseplates are weighted or anchored using concrete/ballast for wind resistance up to 19 m/s (per AS 4687).

- Q5: What testing is performed for weld integrity?

- A5: Mechanical tensile testing (ASTM E8), bend test (ISO 7438), and visual inspection; each weld withstands ≥800N pull force (per EN 10223-7).

- Q6: Can Welded Wire Mesh Temporary Fence be re-used for multiple projects?

- A6: Yes; designed for rapid disassembly/reassembly with robust surface protection, suitable for 5–8 installations over 8–15 years.

- Q7: Which international certifications are supported?

- A7: Products are certified under ISO (9001, 1461, 9227), ANSI, CSA, and can be provided to meet AS/NZS or local standards, with third-party inspection (SGS/BV).

10. References & Authoritative Sources

- MarketsandMarkets™, Temporary Fencing Market by Type, 2023: https://www.marketsandmarkets.com/Market-Reports/temporary-fencing-market-144205013.html

- ISO 1461: Hot-dip galvanized coatings on fabricated iron and steel articles - Specifications and test methods: https://www.iso.org/standard/56032.html

- ASTM B117-16: Standard Practice for Operating Salt Spray (Fog) Apparatus: https://www.astm.org/b117-16.html

- AU Industry Fencing Forum: Technical Peer Reviews and Case Studies, 2023: https://www.fencingonline.com.au/forum/temp-fence-specs

- AS/NZS 4687:2007 Temporary fencing and hoardings: https://infostore.saiglobal.com/en-au/standards/as-nzs-4687-2007-163854_saig_as_as_389768/

- LinkedIn Industry Feedback (Project Case Study): https://www.linkedin.com/pulse/case-study-event-fencing

-

Types and Uses of Common Nails in Construction

NewsJul.31,2025

-

The Transformative Role of Square Wire Mesh in Contemporary Architecture

NewsJul.31,2025

-

The Essential Role of Razor Wire in Modern Perimeter Security

NewsJul.31,2025

-

Installation Guide for Hexagonal Wire Netting Fencing

NewsJul.31,2025

-

How to Properly Use Rebar Wire Ties for Stronger Concrete Structures

NewsJul.31,2025

-

Creative and Decorative Uses of Barbed Wire in Design

NewsJul.31,2025