Top Manufacturers of 0.45mm Galvanized Wire for Various Applications

Understanding 0.45mm Galvanized Wire Manufacturers and Applications

Galvanized wire, particularly the 0.45mm variant, has become increasingly popular in various industries due to its durability, corrosion resistance, and versatility. This type of wire is coated with a layer of zinc, providing an additional protective barrier that enhances its life span, even in harsh environments. Manufacturers specializing in 0.45mm galvanized wire play a critical role in producing high-quality materials that cater to a wide range of applications.

The Manufacturing Process

The production of 0.45mm galvanized wire begins with high-quality steel wire rods. These rods undergo a series of processes that include drawing and annealing, which reduce their diameter and improve ductility. After achieving the desired thickness, the wire is subjected to the galvanizing process, where it is immersed in molten zinc. This process not only coats the wire with zinc but also allows for a metallurgical bond that ensures the coating remains intact even under stress.

Leading manufacturers in the industry utilize advanced technology and rigorous quality control measures to guarantee the wire meets international standards. This includes testing for tensile strength, flexibility, and corrosion resistance. A reputable manufacturer will ensure that their galvanized wire adheres to specifications set by organizations such as ASTM (American Society for Testing and Materials).

Applications of 0.45mm Galvanized Wire

0.45mm galvanized wire manufacturers

0.45mm galvanized wire is widely used in various applications across different sectors. One of the most common uses is in the agricultural industry, where it is utilized for fencing, ensuring livestock is contained while providing durability against the elements. Furthermore, it is frequently used to create supports and trellises for climbing plants.

In construction, this wire can be employed for reinforcement in concrete structures, mesh works, and as binding wire for rebar. Its corrosion-resistant properties make it particularly suitable for outdoor projects. Additionally, 0.45mm galvanized wire is often used in manufacturing applications, including the production of wire baskets, hangers, and other components that require a robust wire solution.

Choosing the Right Manufacturer

When selecting a manufacturer for 0.45mm galvanized wire, consider their production capabilities, expertise, and certifications. A good manufacturer will not only provide high-quality products but also offer customization options to meet specific project requirements. Engaging with manufacturers who emphasize sustainable practices can also have long-term benefits for the environment.

In conclusion, 0.45mm galvanized wire stands out for its strength and resilience, making it a preferred choice in various applications. The role of manufacturers in producing this high-quality wire is essential, ensuring that industries can rely on durable materials that stand the test of time.

-

Unlock the Strength and Versatility of Steel Wire

NewsJun.04,2025

-

The Ultimate Guide to Welded Wire Mesh

NewsJun.04,2025

-

Secure Your Structures with Premium Anchor Bolts

NewsJun.04,2025

-

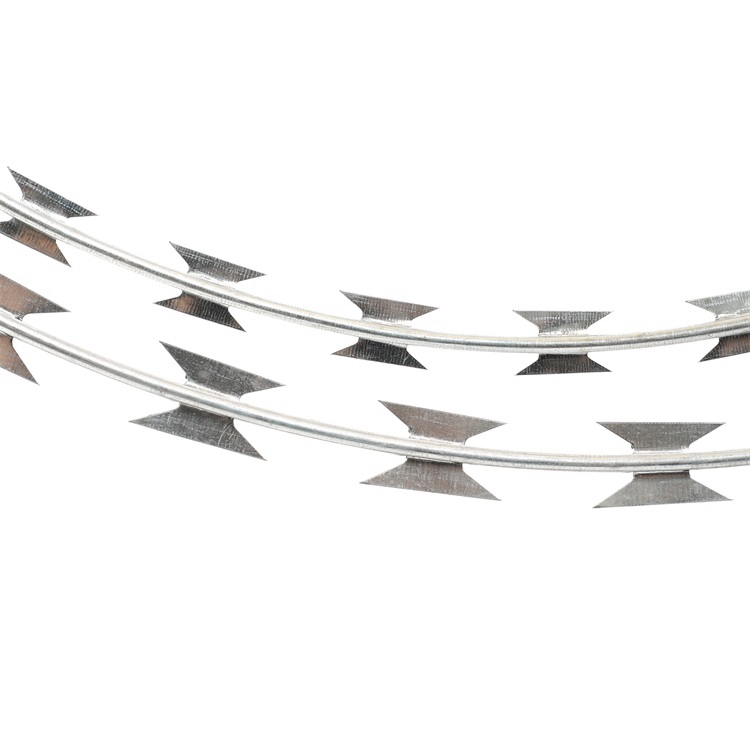

Protect Your Property with High-Quality Razor Wire

NewsJun.04,2025

-

Everything You Need to Know About Concrete Nails

NewsJun.04,2025

-

Durable and Reliable Metal Posts for All Your Fencing Needs

NewsJun.04,2025