raw material for common nails pricelist

Understanding the Pricing of Raw Materials for Common Nails

When it comes to manufacturing common nails, the raw materials used play a crucial role in determining the overall quality, strength, and cost of the final product. Common nails are essential fasteners in various construction and woodworking projects, making the pricing of their raw materials highly significant in the industry. This article aims to delve into the factors affecting the prices of raw materials required for common nails and discuss their implications.

Key Raw Materials

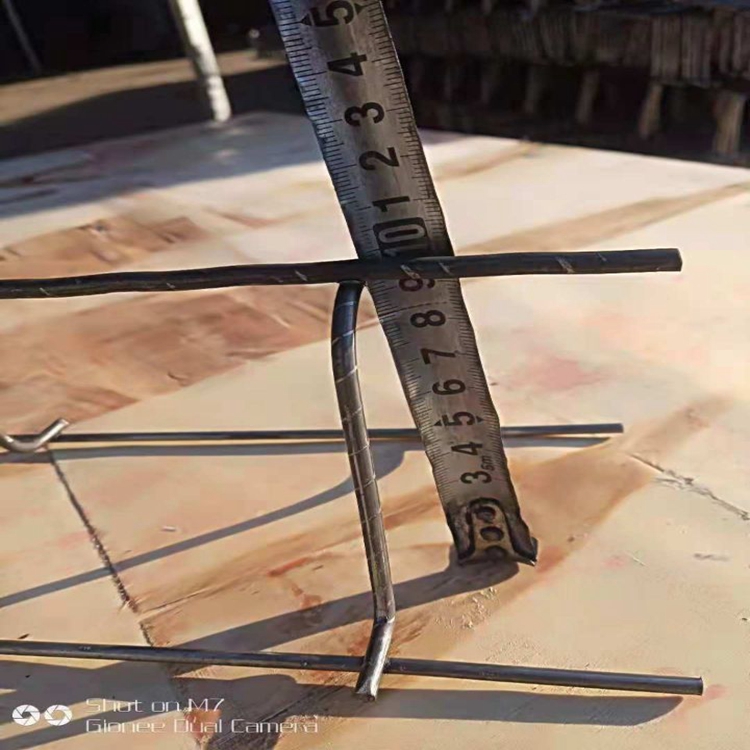

The main raw material for common nails is steel, typically produced in wire form. The specific types of steel used can vary, but carbon steel often dominates due to its strength and durability. Other materials, such as coatings for rust resistance (like zinc or vinyl), also factor into the overall costs. The quality of the raw materials directly influences the price, performance, and application of the nails.

Factors Influencing Prices

1. Market Demand and Supply The prices of raw materials are subject to fluctuations based on market dynamics. When the demand for construction projects increases, the demand for nails—and consequently the raw materials needed for their production—also rises. Conversely, during economic downturns, the demand can diminish, leading to lower prices.

2. Raw Material Availability The availability of steel and its derivatives significantly impacts pricing. Factors such as mining outputs, geopolitical situations, and trade policies can affect the supply of iron ore, a primary component in steel production, thus influencing nail manufacturing costs.

3. Production Costs The costs involved in the production of raw materials play a significant role. These include energy costs (for the manufacturing processes), labor costs, and transportation. Energy prices, in particular, can have a pronounced effect, as they impact the cost of producing steel and transporting it to manufacturers.

raw material for common nails pricelist

4. Technological Advancements Innovations in manufacturing processes, such as the use of electric arc furnaces or improvements in recycling practices, can lead to more efficient production methods. This can potentially lower raw material costs, making it more feasible for manufacturers to produce nails at competitive prices.

5. Environmental Regulations Stricter environmental regulations can also lead to increased costs in obtaining raw materials. Compliance with these regulations might require additional investments in technology or processes that can drive up prices.

Implications for the Industry

Understanding the pricing mechanisms of raw materials can help manufacturers make informed decisions regarding procurement and production. Fluctuations in the price of steel and other raw materials will affect profit margins and overall product pricing. For contractors and builders, being aware of these trends can aid in budgeting and project planning.

In addition, manufacturers may explore alternative materials or methods to mitigate costs. For instance, investing in higher-quality raw materials that offer better performance can justify higher initial costs when long-term durability is considered.

Conclusion

In summary, the pricing of raw materials for common nails is influenced by a multidimensional set of factors including market demand, availability, production costs, technological advancements, and environmental regulations. Understanding these dynamics is vital for manufacturers and consumers alike, as it shapes strategies within the construction and manufacturing sectors. As the industry evolves, staying informed about the raw material landscape will be key to maintaining competitiveness and meeting the growing demands of the market.

-

The Durability and Versatility of Steel Wire

NewsJun.26,2025

-

The Best Iron Nails for Your Construction Projects

NewsJun.26,2025

-

Strengthen Your Projects with Durable Metal Stakes

NewsJun.26,2025

-

Get the Job Done Right with Duplex Nails

NewsJun.26,2025

-

Explore the Versatility and Strength of Metal Mesh

NewsJun.26,2025

-

Enhance Your Security with Razor Wire

NewsJun.26,2025