Manufacturer of Pallet Notcher and Cutter Nails for Efficient Woodworking Solutions

The Evolution and Importance of Pallet Notcher and Cutter Nails Manufacturing

In the world of woodworking and packaging, efficiency and precision are paramount. One essential component of this industry is the pallet notcher and cutter nails manufacturer. These manufacturers play a critical role in the production of pallets, which are fundamental in the transportation and storage of goods across various sectors.

Understanding the Pallet Notcher

A pallet notcher is a specialized machine used to create notches in wooden pallets. These notches are essential for ensuring that the pallets can securely attach together, providing stability for the loads they carry. By making precise cuts, pallet notchers enhance the structural integrity of the pallets, allowing them to safely transport heavy items without risk of collapse.

Modern pallet notchers utilize advanced technology, including CNC (computer numerical control) systems, which enable manufacturers to program accurate cutting patterns. This automation increases efficiency while reducing the likelihood of human error. Manufacturers that invest in these advanced machines can improve productivity and lower production costs, making them more competitive in the market.

The Role of Cutter Nails

Cutter nails, sometimes known as pallet nails or cleat nails, are another vital aspect of pallet production. These nails are designed specifically for fastening pallets securely, ensuring that they can withstand the rigors of transportation and handling. Cutter nails differ from regular nails in both design and application; they often feature a unique shape that provides superior holding power.

The manufacturing of cutter nails involves specialized processes, including the selection of appropriate materials and the application of treatments to ensure durability. Quality cutter nails can make the difference between a robust pallet that stands the test of time and one that fails under pressure. Therefore, manufacturers must adhere to strict quality control measures to guarantee that each nail produced meets industry standards.

pallet notcher cutter nails manufacturer

Innovations in Manufacturing

As the logistics and shipping industries evolve, so too must the manufacturing processes for pallet notcher and cutter nails. Innovations such as sustainable materials, eco-friendly production practices, and advanced machinery are increasingly becoming standard. Many manufacturers are now focusing on reducing their carbon footprint by using recycled materials and implementing energy-efficient technologies.

Moreover, digitalization is transforming the manufacturing landscape. Industry 4.0 technologies, including IoT (Internet of Things) devices and real-time monitoring systems, allow manufacturers to track production processes closely. This capability not only enhances efficiency but also enables manufacturers to anticipate maintenance needs, reducing downtime and maximizing output.

Market Demand and Future Prospects

The demand for pallets, and consequently for pallet notcher and cutter nails, is expected to continue growing. With the rise of e-commerce and global trade, the logistics sector is expanding rapidly. This growth drives the need for durable and reliable packaging solutions, making the role of pallet notcher and cutter nails manufacturers even more crucial.

Looking ahead, manufacturers that embrace technological advancements and sustainable practices will likely have a competitive edge. As consumers become more environmentally conscious, the demand for eco-friendly pallets and fasteners will rise. Manufacturers will need to adapt to these trends to meet consumer expectations while also maintaining efficiency and quality.

Conclusion

In conclusion, the manufacturing of pallet notchers and cutter nails is an essential segment of the woodworking and logistics industries. As technology continues to evolve, manufacturers who invest in innovation and sustainability are positioned to thrive in a competitive market. The importance of high-quality pallets, reinforced by robust notching and fastening solutions, cannot be overstated, as they serve as the backbone of effective supply chain management. The future of pallet notcher and cutter nails manufacturing is bright, with numerous opportunities for growth and development.

-

Types and Uses of Common Nails in Construction

NewsJul.31,2025

-

The Transformative Role of Square Wire Mesh in Contemporary Architecture

NewsJul.31,2025

-

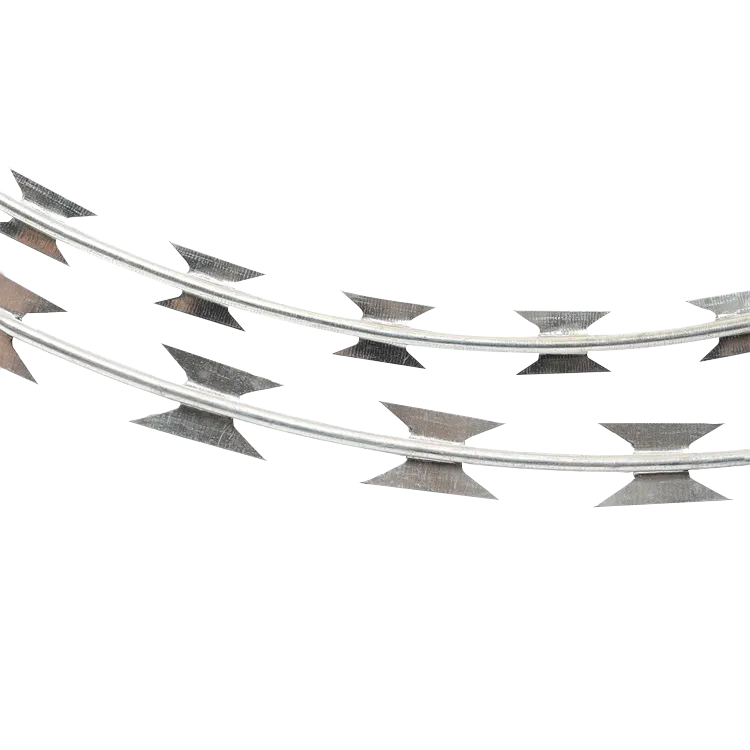

The Essential Role of Razor Wire in Modern Perimeter Security

NewsJul.31,2025

-

Installation Guide for Hexagonal Wire Netting Fencing

NewsJul.31,2025

-

How to Properly Use Rebar Wire Ties for Stronger Concrete Structures

NewsJul.31,2025

-

Creative and Decorative Uses of Barbed Wire in Design

NewsJul.31,2025