Bare Tie Wire Manufacturing Facility for Quality Wire Production and Supply

The Bare Tie Wire Factory An Insight into Wire Manufacturing

In the manufacturing landscape, few products are as essential yet overlooked as tie wire. At the forefront of this industry is the Bare Tie Wire Factory, a facility dedicated to producing high-quality tie wire for construction and various industrial applications. This article delves into the significance of tie wire, the manufacturing process, and the advantages of choosing the Bare Tie Wire Factory for your wire needs.

The Bare Tie Wire Factory An Insight into Wire Manufacturing

The manufacturing process at the Bare Tie Wire Factory is a blend of innovation and traditional craftsmanship. The raw materials used are sourced from reputable suppliers, ensuring that the wire produced is of the highest quality. The process begins with wire drawing, where large coils of raw steel are drawn through a series of dies to produce thinner wires. This step is critical, as it determines the wire's diameter and tensile strength, which are vital for its application in construction.

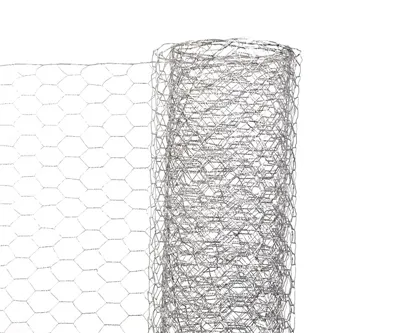

bare tie wire factory

Once the wire is drawn, it undergoes annealing, a process that involves heating the wire to specific temperatures and then cooling it down in a controlled manner. This step is essential as it increases the ductility of the wire, making it easier to work with during construction. After annealing, the wire is then subjected to quality control checks, where it is inspected for any defects. The Bare Tie Wire Factory prides itself on maintaining stringent quality standards, ensuring that every coil of wire meets the industry specifications and customer expectations.

One of the key advantages of sourcing tie wire from the Bare Tie Wire Factory is the commitment to sustainability. The factory adheres to environmentally friendly practices in its manufacturing process, aiming to reduce waste and minimize its carbon footprint. By choosing products from the Bare Tie Wire Factory, customers can feel confident that they are supporting sustainable manufacturing practices.

Moreover, the Bare Tie Wire Factory offers a wide variety of products to meet diverse customer needs. From low-carbon steel tie wire to high-strength alternatives, the factory caters to a broad spectrum of applications. Customers appreciate the flexibility in ordering, as the factory can accommodate both large-scale orders and smaller batches, ensuring that construction projects of all sizes receive the materials they require.

In conclusion, the Bare Tie Wire Factory represents a critical player in the wire manufacturing industry. Through its dedication to quality, sustainability, and customer service, the factory not only meets the demands of the construction sector but also sets a standard for others to follow. By choosing the Bare Tie Wire Factory, contractors and builders can ensure they are using reliable, high-quality tie wire essential for the integrity of their projects.

-

Unlock the Strength and Versatility of Steel Wire

NewsJun.04,2025

-

The Ultimate Guide to Welded Wire Mesh

NewsJun.04,2025

-

Secure Your Structures with Premium Anchor Bolts

NewsJun.04,2025

-

Protect Your Property with High-Quality Razor Wire

NewsJun.04,2025

-

Everything You Need to Know About Concrete Nails

NewsJun.04,2025

-

Durable and Reliable Metal Posts for All Your Fencing Needs

NewsJun.04,2025