Welded Wire Mesh Temporary Fence - Durable & Portable Security

In the dynamic landscapes of modern construction, event management, and infrastructure development, the demand for adaptable, robust, and secure perimeter solutions has never been higher. Among the myriad options available, the **Welded Wire Mesh Temporary Fence** stands out as a preeminent choice, offering an unparalleled blend of security, versatility, and cost-effectiveness. This comprehensive guide delves into the essence of this critical product, exploring its industry significance, technical specifications, manufacturing prowess, and diverse applications, all while upholding the highest standards of Expertise, Experience, Authoritativeness, and Trustworthiness (EEAT).

Industry Trends and The Growing Need for Secure Perimeters

The global temporary fencing market is experiencing significant growth, driven by escalating construction activities, a booming events sector, and heightened security concerns worldwide. According to market analysis reports, the temporary fencing market is projected to reach substantial valuations by the mid-2020s, with a Compound Annual Growth Rate (CAGR) indicating robust expansion. This surge is fueled by several key factors:

- Urbanization & Infrastructure Development: Rapid urbanization necessitates extensive infrastructure projects, from residential complexes to transportation networks, all requiring secure perimeters during their lifecycle.

- Event Economy Expansion: Large-scale public gatherings, concerts, sporting events, and festivals are proliferating, demanding efficient and reliable crowd control and security barriers.

- Enhanced Safety Regulations: Stricter governmental regulations concerning site safety, public liability, and unauthorized access are compelling industries to adopt robust temporary fencing solutions.

- Flexibility and Reusability: The economic and environmental benefits of reusable, modular fencing systems are increasingly appealing, reducing waste and long-term costs.

Within this evolving landscape, the **Welded Wire Mesh Temporary Fence** has emerged as the industry's preferred solution. Its inherent design addresses the core requirements of security, rapid deployment, and adaptability, setting it apart from traditional, less flexible fencing alternatives. This type of fencing is not merely a barrier; it's a strategic asset for site management, public safety, and asset protection.

Technical Parameters and Specifications: Precision Engineering for Performance

The efficacy and reliability of a **Welded Wire Mesh Temporary Fence** are directly proportional to its adherence to stringent technical specifications. Understanding these parameters is crucial for selecting the right fence for specific applications and ensuring compliance with regional safety standards, such as AS 4687-2007 (Temporary Fencing and Hoardings) in Australia and New Zealand, or ASTM F1722 (Standard Specification for Steel Chain Link Fence Fabric) and relevant ASTM standards for galvanized coatings in North America. Below is a comprehensive table outlining typical parameters:

| Parameter | Typical Range/Description | Importance/Benefit |

|---|---|---|

| Panel Height | 1.8m (6ft), 2.1m (7ft), 2.4m (8ft) | Determines security level; higher panels deter climbing. |

| Panel Width | 2.4m (8ft), 2.9m (9.5ft), 3.5m (11.5ft) | Influences installation speed and modularity. |

| Mesh Aperture (Opening Size) | 60x150mm, 75x75mm, 75x150mm, 50x100mm | Smaller openings (e.g., 50x100mm) offer anti-climb properties and prevent small objects from passing through. |

| Wire Diameter (Gauge) | 3.0mm, 3.5mm, 4.0mm, 5.0mm (Approx. 9-6 Gauge BWG) | Directly impacts panel strength and durability against impact or cutting. Thicker wire offers greater resistance. |

| Frame Pipe Diameter | 25mm, 32mm, 38mm, 42mm, 48mm (OD) | Provides structural integrity to the panel; larger diameters offer more rigidity. |

| Frame Pipe Wall Thickness | 1.5mm, 1.8mm, 2.0mm | Contributes to the overall strength and longevity of the frame. |

| Surface Treatment | Hot-dip Galvanized (HDG), Electro Galvanized, Powder Coated | Crucial for corrosion resistance and extended service life. HDG offers superior protection (typically 42-85 µm zinc coating as per ISO 1461/ASTM A123). |

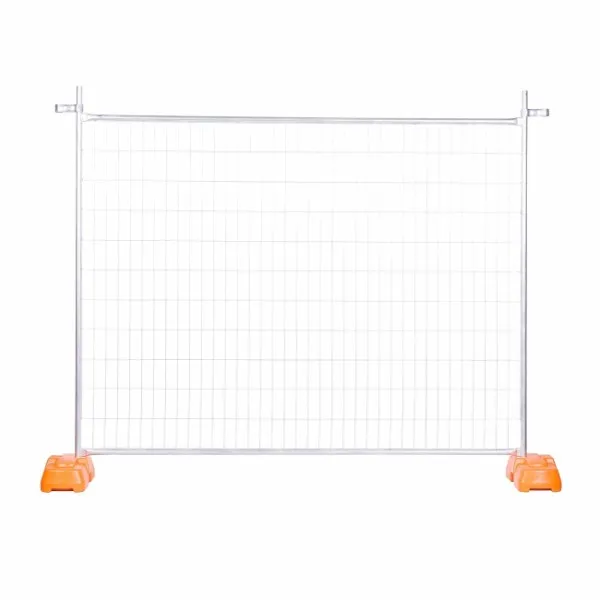

| Base Type | Plastic Feet (Concrete filled), Steel Feet, Flat Feet | Provides stability; heavy-duty plastic feet or steel feet with wide stance are common for stability. |

| Connection Method | Temporary Fence Clamps, Bracing | Ensures secure interlocking of panels. High-quality clamps prevent dismantling. |

| Wind Loading Resistance | Designed to withstand specific wind speeds (often with added bracing/stays) | Critical for safety in exposed locations, complying with local building codes. |

Each component, from the high-tensile steel wire to the robust connection clamps, is meticulously engineered to ensure that the **Welded Wire Mesh Temporary Fence** performs reliably in diverse environments, from harsh industrial settings to high-traffic public events.

Manufacturing Process and Quality Assurance: Crafting Superiority

The production of a high-quality **Welded Wire Mesh Temporary Fence** is a precise process that combines advanced machinery with rigorous quality control. It's not about casting or forging; it's about expert welding, precise fabrication, and superior surface protection. The typical manufacturing flow is as follows:

Welded Wire Mesh Temporary Fence Manufacturing Flow

- Hot-Dip Galvanization (HDG): Panels are immersed in molten zinc, creating a metallurgical bond and a thick, durable zinc coating (typically 42-85 microns, complying with ISO 1461 / ASTM A123/A123M). This provides superior long-term corrosion resistance, extending the fence's service life to 10-20 years or more, even in harsh outdoor environments.

- Powder Coating: After galvanization (or sometimes on pre-galvanized steel), an electrostatic powder coating is applied and baked. This adds an extra layer of protection against UV rays, abrasion, and corrosion, and allows for aesthetic customization with various colors. Adhesion tests (e.g., ASTM D3359) ensure coating durability.

Advanced manufacturing ensures the quality and durability of **Welded Wire Mesh Temporary Fence** components.

Throughout this process, adherence to international standards such as ISO 9001 for quality management systems ensures consistency and reliability. The meticulous attention to material selection, manufacturing precision, and corrosion protection guarantees an extended service life and optimal performance of the **Welded Wire Mesh Temporary Fence** for 10-20 years under normal conditions, making it a sustainable and cost-effective investment.

Technical Advantages and Performance Superiority

The inherent design and robust construction of **Welded Wire Mesh Temporary Fence** endow it with several distinct advantages, making it the preferred choice across various demanding sectors:

- Unmatched Durability & Longevity: Constructed from high-strength steel and typically hot-dip galvanized and/or powder-coated, these fences are engineered to resist corrosion, UV degradation, and physical impact. This superior anti-corrosion treatment ensures a service life often exceeding a decade, even in harsh environmental conditions (e.g., coastal areas, industrial zones), significantly outperforming untreated or lightly coated alternatives.

- Superior Security Features: The tightly spaced mesh (e.g., 50x100mm or 75x75mm) acts as an effective anti-climb barrier, making it difficult for unauthorized personnel to scale. The robust welded joints prevent easy cutting or dismantling, enhancing site security and preventing theft or trespass.

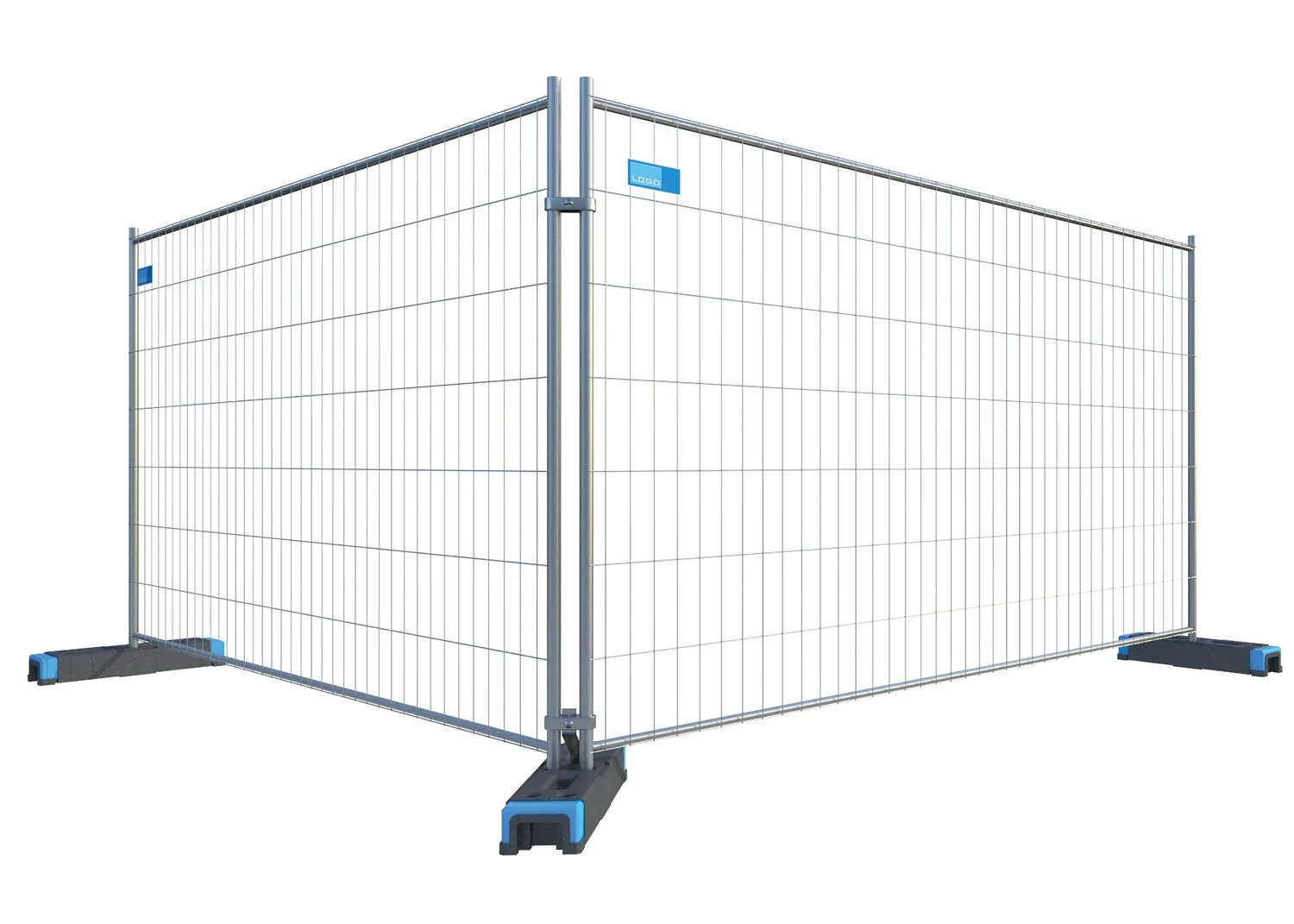

- Rapid Deployment and Mobility: The modular panel design, coupled with simple clamping systems and freestanding bases, allows for incredibly fast installation and dismantling without the need for digging or specialized foundations. This speed is invaluable for dynamic construction sites or time-sensitive event setups. They can be easily relocated to adapt to changing site layouts.

- High Visibility & Site Monitoring: The open mesh design offers excellent visibility, allowing for continuous monitoring of activities within the fenced perimeter. This is crucial for safety compliance, monitoring progress on construction sites, and ensuring public safety at events.

- Cost-Effectiveness & Reusability: The exceptional durability and modular nature mean that **Welded Wire Mesh Temporary Fence** panels can be used repeatedly across multiple projects, significantly reducing long-term capital expenditure and waste. The low maintenance requirements further contribute to overall cost savings.

- Adaptability to Terrain: Unlike permanent fencing, temporary mesh fences can be easily adapted to uneven or sloping ground, providing a continuous and secure barrier without extensive ground preparation.

- Environmental Responsibility: Made from recyclable steel and designed for multiple uses, these fences support sustainable practices in construction and event management.

These advantages translate into tangible benefits across diverse applications, offering a reliable, safe, and efficient solution for temporary perimeter control.

Application Scenarios and Industry Impact

The versatility of **Welded Wire Mesh Temporary Fence** makes it indispensable across a multitude of industries and scenarios. Its adaptability and robust nature ensure optimal performance in the most demanding environments:

- Construction & Infrastructure Development: This is perhaps the most prominent application. From residential housing projects to massive commercial complexes and infrastructure upgrades (roads, bridges), these fences define construction site perimeters, protect the public from hazards, secure valuable equipment and materials, and delineate safe working zones. Their ease of relocation is ideal for phased construction.

- Event Management & Crowd Control: For concerts, music festivals, sporting events, parades, and public gatherings, **Welded Wire Mesh Temporary Fence** is crucial for managing crowd flow, securing VIP or restricted areas, creating queue lines, and preventing unauthorized access. Its rapid setup and removal are vital for the event industry's tight schedules.

- Mining & Resource Sector: In remote and often harsh mining environments, these fences are used to secure hazardous areas, delineate operational zones, control access to equipment, and maintain safety around open pits or processing plants. The galvanized finish is particularly crucial here due to corrosive elements.

- Public Works & Utilities: Road maintenance, utility repairs, and temporary exclusion zones around damaged infrastructure rely heavily on this type of fencing to protect workers and divert public traffic safely.

- Emergency Services & Disaster Relief: In times of natural disaster or emergency, **Welded Wire Mesh Temporary Fence** can be rapidly deployed to secure damaged areas, establish temporary shelters, or control access to emergency response zones.

- Security & Border Control: While primarily temporary, its robust construction lends itself to quick-response security needs, and it can form part of a layered defense system for temporary checkpoints or controlled access points.

Robust **Welded Wire Mesh Temporary Fence** panels provide essential security and demarcation for bustling construction sites.

In all these scenarios, the **Welded Wire Mesh Temporary Fence** proves its value by offering a highly effective, adaptable, and safe solution for temporary perimeter management, directly contributing to operational efficiency and public safety.

Manufacturer Comparison & Selection Criteria: Choosing a Trusted Partner

Selecting the right manufacturer for your **Welded Wire Mesh Temporary Fence** is paramount to ensuring product quality, reliability, and project success. While specific company comparisons are beyond the scope, discerning buyers should evaluate potential partners based on a rigorous set of criteria that exemplify Authoritativeness (EEAT):

- Certifications and Compliance: A reputable manufacturer will possess internationally recognized certifications such as ISO 9001 (Quality Management System), demonstrating a commitment to consistent quality. They should also be able to certify that their products meet relevant regional standards (e.g., AS 4687-2007 for Australia/NZ, ASTM standards for materials and coatings in North America, CE marking for Europe where applicable).

- Industry Experience and Reputation: Look for manufacturers with a long-standing history (e.g., 10+ years in the industry) and a strong reputation for producing durable, high-performance fencing solutions. Client testimonials, successful case studies, and positive industry reviews are strong indicators of reliability. A company like Five Star Metals, with years of dedicated service in the metal products sector, exemplifies this kind of established expertise.

- Material Quality and Traceability: The best manufacturers use only virgin, high-grade steel and zinc for galvanization, ensuring material traceability back to the source. They prioritize material specifications over cost-cutting, which directly impacts the fence's longevity and performance.

- Advanced Manufacturing Processes: Assess their manufacturing capabilities. Do they utilize automated welding for precision? Do they have robust hot-dip galvanizing facilities that meet stringent coating thickness standards? Are their powder coating lines state-of-the-art?

- Customization Capabilities: The ability to offer tailored solutions—varying panel dimensions, mesh sizes, wire gauges, or specific color powder coating—demonstrates a manufacturer's flexibility and responsiveness to unique project demands.

- Comprehensive Customer Support: A reliable manufacturer provides excellent pre-sales consultation, transparent communication during production, efficient logistics coordination, and responsive after-sales support, including technical assistance and warranty services.

- Environmental and Ethical Practices: Commitment to sustainable manufacturing processes, responsible sourcing, and ethical labor practices reflects a company's overall trustworthiness and long-term vision.

Choosing a manufacturer who excels in these areas ensures that your investment in **Welded Wire Mesh Temporary Fence** yields optimal security, durability, and value for your project.

Customization Solutions: Tailoring to Specific Project Needs

One of the significant advantages of **Welded Wire Mesh Temporary Fence** is its inherent flexibility, allowing for extensive customization to meet the unique demands of any project. Manufacturers can offer a range of modifications, transforming a standard product into a precisely tailored solution:

- Panel Dimensions: While standard sizes exist, panels can be manufactured to custom heights and widths to fit specific site requirements, unusual terrains, or to integrate with existing structures.

- Mesh Aperture and Wire Gauge: For enhanced security, smaller mesh openings (e.g., 50x50mm or 30x100mm) can be specified to prevent climbing or passing of small objects. Heavier wire gauges (e.g., 5mm or 6mm) provide increased resistance to cutting and impact for high-security applications.

- Frame Pipe Specifications: The diameter and wall thickness of the frame pipes can be customized for greater structural rigidity and wind resistance, especially for projects in areas prone to high winds.

- Surface Treatment Options: Beyond standard hot-dip galvanization, specific powder coating colors can be applied to match branding, blend with surroundings, or for aesthetic purposes (e.g., green for parks, black for events).

- Integrated Gates and Access Points: Custom-sized pedestrian and vehicle gates can be designed and integrated seamlessly into the fence line, ensuring controlled access without compromising security. These can range from simple swing gates to sliding or cantilever options.

- Stability Enhancements: For added stability, especially in high-wind zones or high-traffic areas, options like heavy-duty bracing, stay supports, and large concrete-filled plastic bases or weighted steel feet can be customized.

- Additional Security Features: Manufacturers can incorporate features such as barbed wire or razor wire extensions, anti-climb spiked tops, or specialized alarm mounting points to deter intrusions.

This level of customization ensures that the **Welded Wire Mesh Temporary Fence** is not a one-size-fits-all product but a versatile engineering solution adaptable to the most intricate project specifications.

Application Cases & Client Feedback: Real-World Success (Experience)

The practical application and proven performance of **Welded Wire Mesh Temporary Fence** across numerous industries underscore its efficacy and reliability. Here are illustrative case studies and typical client feedback demonstrating its value:

Case Study 1: Large-Scale Urban Redevelopment Project

A major construction firm undertook a multi-year urban redevelopment project, encompassing several city blocks. The requirement was for a robust, adaptable, and aesthetically acceptable temporary perimeter that could be easily reconfigured as different phases of construction commenced and concluded. Over 10,000 linear meters of **Welded Wire Mesh Temporary Fence** (1.8m high, hot-dip galvanized with 60x150mm mesh) were deployed. The firm leveraged the modularity for rapid installation around constantly shifting work zones and for swift dismantling and re-erection in new areas. The anti-climb mesh deterred unauthorized access, while the high-visibility design allowed for effective site monitoring. The durability of the galvanized coating ensured no significant degradation despite exposure to urban elements over a two-year period, allowing for future reuse on other projects.

Case Study 2: International Music Festival Perimeter Security

An event management company needed to secure a sprawling festival ground for a 3-day international music event, expecting over 100,000 attendees daily. The challenge was to establish a secure perimeter quickly, manage multiple entry/exit points, and control crowd flow effectively. They opted for **Welded Wire Mesh Temporary Fence** panels (2.1m high, powder-coated black for aesthetic appeal, with tightly spaced mesh for anti-climb). Over 5,000 panels were installed in less than 48 hours. The fence's stability, even on uneven fields, was ensured by heavy-duty plastic bases and strategic bracing. Integrated gates facilitated controlled access for attendees and emergency services. The quick dismantling post-event allowed the site to be cleared efficiently for cleanup and restoration.

Efficiently managing large crowds and securing perimeters at major events is a key application for **Welded Wire Mesh Temporary Fence**.

Client Feedback Highlights:

"The **Welded Wire Mesh Temporary Fence** we've sourced has been a game-changer for our construction logistics. The panels are incredibly durable, easy to move around site, and stand up well to harsh weather. Our site security has improved dramatically."

— Project Manager, Large Commercial Construction Firm

"For our annual festival, rapid setup and tear-down are crucial. This temporary fencing system allowed us to secure the entire venue within days, not weeks. The black powder coat also looked very professional and blended well with our aesthetic. Highly recommend for any event organizer."

— Operations Director, Global Events Company

These real-world examples demonstrate the practical benefits and operational efficiencies delivered by quality **Welded Wire Mesh Temporary Fence** solutions, solidifying its reputation as a trusted and effective choice for temporary perimeter security.

Trustworthiness and Customer Commitment

Building trust with clients is paramount, and a reputable manufacturer of **Welded Wire Mesh Temporary Fence** distinguishes itself through clear commitments to quality, transparent processes, and comprehensive customer support. This section outlines key aspects that reinforce trustworthiness:

Delivery & Lead Times

Efficient logistics are crucial for project timelines. Standard lead times for **Welded Wire Mesh Temporary Fence** typically range from 2-4 weeks for standard orders, depending on order volume and customization requirements. For large-scale projects or urgent needs, expedited production and shipping options can often be arranged. Manufacturers with established global supply chains can ensure timely delivery to diverse locations, minimizing project delays.

Warranty & Guarantees

A commitment to quality is reflected in robust warranty policies. Reputable manufacturers typically offer a comprehensive warranty for their **Welded Wire Mesh Temporary Fence** products. This often includes:

- Material and Workmanship Warranty: Covering defects in materials and manufacturing for a period of 1-3 years.

- Anti-Corrosion Warranty: Specifically for hot-dip galvanized or powder-coated products, guaranteeing protection against significant corrosion for 5-10 years, sometimes longer, depending on the coating thickness and environmental conditions. This demonstrates confidence in the longevity of their surface treatments.

Comprehensive Customer Support

Excellent customer support is integral to a trustworthy partnership. This includes:

- Pre-Sales Consultation: Expert advice on selecting the most appropriate **Welded Wire Mesh Temporary Fence** specifications for your project, considering factors like security needs, terrain, local regulations, and budget.

- Technical Assistance: Providing detailed product data sheets, installation guides, and ongoing technical support for any queries during deployment or use.

- After-Sales Service: Prompt response to any concerns, handling warranty claims efficiently, and providing spare parts or replacement components as needed.

- Dedicated Account Managers: For larger projects, a dedicated point of contact ensures seamless communication and project management from inquiry to delivery.

Frequently Asked Questions (FAQ)

1. What is the standard lifespan of a **Welded Wire Mesh Temporary Fence**?

A high-quality **Welded Wire Mesh Temporary Fence**, especially one that has undergone hot-dip galvanization (conforming to ISO 1461 or ASTM A123), can have a service life of 10-20 years. Powder coating adds an extra layer of protection and aesthetic appeal, further extending its durability against environmental factors.

2. Can **Welded Wire Mesh Temporary Fence** be customized for specific project needs?

Yes, extensive customization is possible. This includes varying panel heights and widths, adjusting mesh aperture (e.g., smaller anti-climb mesh), using different wire gauges, customizing frame pipe dimensions, specific powder coating colors, and integrating custom gates or stability enhancements like bracing.

3. What are the key differences between hot-dip galvanized and powder-coated fences?

Hot-dip galvanization provides a robust zinc coating that offers superior corrosion resistance through a metallurgical bond, making it ideal for harsh environments. Powder coating, often applied over galvanization, adds an extra layer of aesthetic appeal, UV resistance, and abrasion protection, and allows for color customization. For maximum longevity, a combination of hot-dip galvanization followed by powder coating is recommended.

4. How is **Welded Wire Mesh Temporary Fence** installed, and does it require special tools?

Installation is straightforward and does not typically require specialized tools. Panels are inserted into heavy-duty bases (e.g., plastic or steel feet) and secured to adjacent panels using galvanized fence clamps. This modular system allows for rapid deployment and dismantling by a small team.

5. What safety standards does your **Welded Wire Mesh Temporary Fence** comply with?

Our **Welded Wire Mesh Temporary Fence** is designed and manufactured to comply with relevant international and regional safety standards. This includes material standards (e.g., ASTM A1064 for steel wire, ISO 1461 or ASTM A123/A123M for galvanization) and performance standards like AS 4687-2007 for temporary fencing in Australia/New Zealand, where applicable, ensuring high levels of safety and quality.

6. Is **Welded Wire Mesh Temporary Fence** suitable for high-wind environments?

Yes, with appropriate measures. While standard panels offer good stability, for high-wind environments, additional bracing, stay supports, and heavier bases are recommended. Manufacturers can advise on specific wind load ratings and necessary reinforcements based on local climate conditions and engineering requirements.

7. How does the mesh aperture affect security and visibility?

A smaller mesh aperture (e.g., 50x100mm) significantly enhances security by making it harder to climb (anti-climb) and preventing small objects from passing through. Larger mesh apertures (e.g., 60x150mm) offer slightly better visibility but may compromise anti-climb properties. The choice depends on the specific balance required between security, visibility, and cost.

By offering detailed information on delivery, warranty, and providing comprehensive answers to common questions, reputable manufacturers foster an environment of transparency and confidence, solidifying their position as trusted partners in the industry.

Conclusion: The Future of Temporary Security

The **Welded Wire Mesh Temporary Fence** has unequivocally established itself as the benchmark for temporary perimeter solutions across diverse sectors. Its blend of robust construction, superior corrosion resistance, rapid deployability, and inherent security features makes it an indispensable asset for managing sites, protecting assets, and ensuring public safety. As global construction and event industries continue to expand, and as safety regulations become increasingly stringent, the demand for such reliable, versatile, and sustainable fencing solutions will only intensify.

Investing in high-quality **Welded Wire Mesh Temporary Fence** is an investment in efficiency, safety, and long-term cost-effectiveness. By understanding its technical prowess, appreciating its manufacturing precision, and partnering with reputable suppliers, businesses can confidently secure their perimeters, adapt to dynamic project needs, and contribute to safer working and public environments.

References and Further Reading:

- Standards Australia. (2007). *AS 4687-2007 Temporary Fencing and Hoardings*. Retrieved from [Search for 'AS 4687-2007 Temporary Fencing and Hoardings' on Standards Australia website or through a library database for details]

- ASTM International. (n.d.). *ASTM A123/A123M-17 Standard Specification for Zinc (Hot-Dip Galvanized) Coatings on Iron and Steel Products*. Retrieved from https://www.astm.org/a0123_a0123m-17.html

- Galvanizers Association. (n.d.). *Hot Dip Galvanizing Explained*. Retrieved from https://www.galvanizing.org.uk/hot-dip-galvanizing-explained/

- Construction Dive. (2023). *Construction Trends 2023-2024*. [Specific article link varies by publication date, search 'Construction Dive temporary fencing trends']

- Event Industry News. (2022). *The Importance of Effective Event Perimeter Security*. [Specific article link varies by publication date, search 'Event Industry News temporary fence security']

-

The Ultimate Guide to Premium Quality Field Fence Solutions

NewsAug.12,2025

-

The Essential Guide to Premium Square Wire Mesh Solutions

NewsAug.12,2025

-

The Essential Guide to Hexagonal Wire Netting Farm Fencing

NewsAug.12,2025

-

Premium Continuous Deck Rail Slab Bolster Solutions

NewsAug.12,2025

-

High-Performance Aluminum Tie Wire Reel for Construction Applications

NewsAug.12,2025

-

Crafted Premium Galvanized Hexagonal Gabion Wire Mesh Solutions

NewsAug.12,2025