raw material barbed wire manufacturer

The Role of Barbed Wire Manufacturers in Raw Material Supply Chains

Barbed wire, a staple in agriculture, security, and fencing applications, serves as a critical barrier against intruders and wildlife. The effectiveness of barbed wire is significantly tied to the quality of its raw materials and the manufacturing process employed to produce it. In this discussion, we will explore the vital role of barbed wire manufacturers, particularly focusing on their sourcing of raw materials, production techniques, and the overall impact on various sectors.

Sourcing Raw Materials

The initial step in barbed wire production revolves around the procurement of raw materials. Steel is the primary component, chosen for its strength and durability. Manufacturers typically utilize high-quality carbon steel, which provides the necessary tensile strength and resistance to rust and corrosion. Suppliers of molten steel play a crucial role in ensuring that manufacturers obtain materials that meet industry standards.

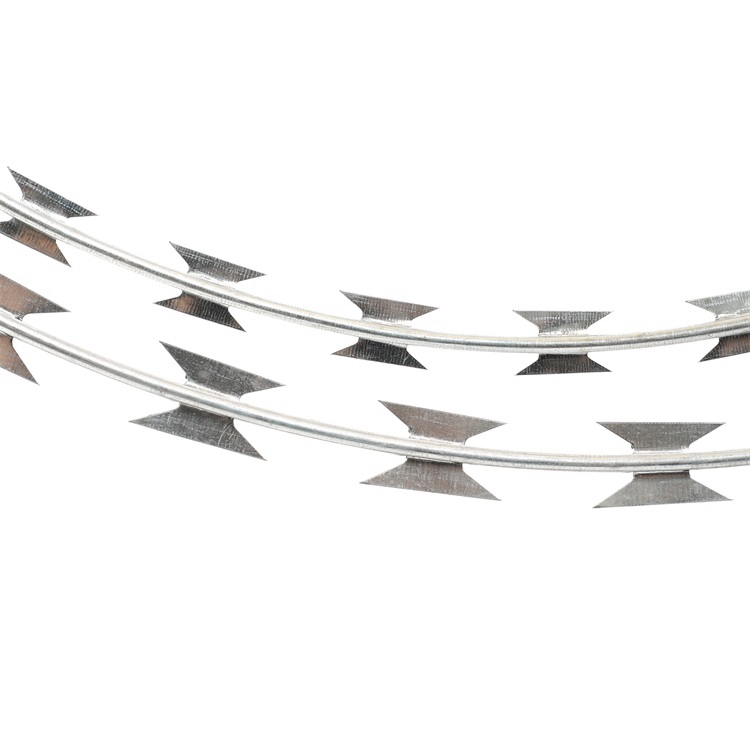

Additionally, coatings such as zinc or polymer are often applied to the wire to enhance its lifespan and protective qualities. Zinc-coated wire, known as galvanized wire, is particularly popular as it withstands harsh environmental conditions and maintains structural integrity over time. Manufacturers must forge robust relationships with suppliers of these raw materials to secure consistent quality and supply.

Manufacturing Techniques

Once the raw materials are secured, the manufacturing process can commence. This process usually begins with wire drawing, where large steel rods are pulled through progressively smaller dies to create thin strands of wire. This stage is critical, as the diameter of the wire directly affects the strength and flexibility of the final product.

After the wire is drawn, it is wound into coils and prepared for the barbing process. The barbing is achieved by feeding the wire through a machine that creates sharp points at regular intervals. These barbs are designed for maximum effectiveness in deterring intruders while also minimizing the risk of injury to livestock and passing wildlife.

raw material barbed wire manufacturer

Quality control measures are essential throughout the manufacturing process. Manufacturers routinely conduct tensile strength tests and corrosion resistance checks to ensure that the finished product meets or exceeds industry standards. The commitment to quality not only safeguards the manufacturer's reputation but also guarantees customer satisfaction.

Impact on Various Sectors

Barbed wire finds applications across diverse sectors, including agriculture, construction, and security. In agriculture, it protects livestock and crops from predators and trespassers alike. Farmers rely on durable barbed wire to create enclosures that are both effective and cost-efficient.

In the construction industry, barbed wire is often used for temporary fencing on job sites, providing a visible deterrent against theft and unauthorized access. Security firms deploy barbed wire in high-risk areas as an additional layer of protection. Jails, border crossings, and property lines benefit from its formidable physical barrier.

Furthermore, as the global demand for security measures increases, barbed wire manufacturers are encouraged to innovate and adapt to market trends. Developing eco-friendly materials and exploring advanced technologies, such as automated manufacturing processes, are essential for future growth and sustainability in this industry.

Conclusion

In summary, barbed wire manufacturers play a pivotal role in the supply chain of raw materials, directly influencing the quality and effectiveness of the product. Their commitment to sourcing high-quality materials, employing advanced manufacturing techniques, and ensuring rigorous quality control is critical for meeting the diverse needs of various industries. As the demand for secure and efficient fencing solutions continues to grow, the significance of these manufacturers in the global market cannot be overstated. By continuously investing in innovation and adhering to quality standards, barbed wire manufacturers will remain integral to protecting property and agricultural interests for years to come.

-

The Durability and Versatility of Steel Wire

NewsJun.26,2025

-

The Best Iron Nails for Your Construction Projects

NewsJun.26,2025

-

Strengthen Your Projects with Durable Metal Stakes

NewsJun.26,2025

-

Get the Job Done Right with Duplex Nails

NewsJun.26,2025

-

Explore the Versatility and Strength of Metal Mesh

NewsJun.26,2025

-

Enhance Your Security with Razor Wire

NewsJun.26,2025