Discount 16D Common Nails & OEM Hardware Deals | Wholesale Bulk

Dingzhou Five-Star Metal Wire Mesh MFG Co.

Global leader in manufacturing premium construction materials with 20+ years of industry expertise. Our solutions meet international quality standards while providing competitive pricing through optimized manufacturing processes.

Industry Context: Construction Fasteners Market

Global construction fastener markets exhibit 6.8% CAGR (2023-2030), driven by infrastructure development in emerging economies and sustainable building initiatives worldwide. Discount 16D common nails remain foundational in wood framing applications, with projected 2025 market valuation of $8.9 billion. Current industry challenges include raw material price volatility and supply chain disruptions, highlighting the importance of partnering with reliable manufacturers.

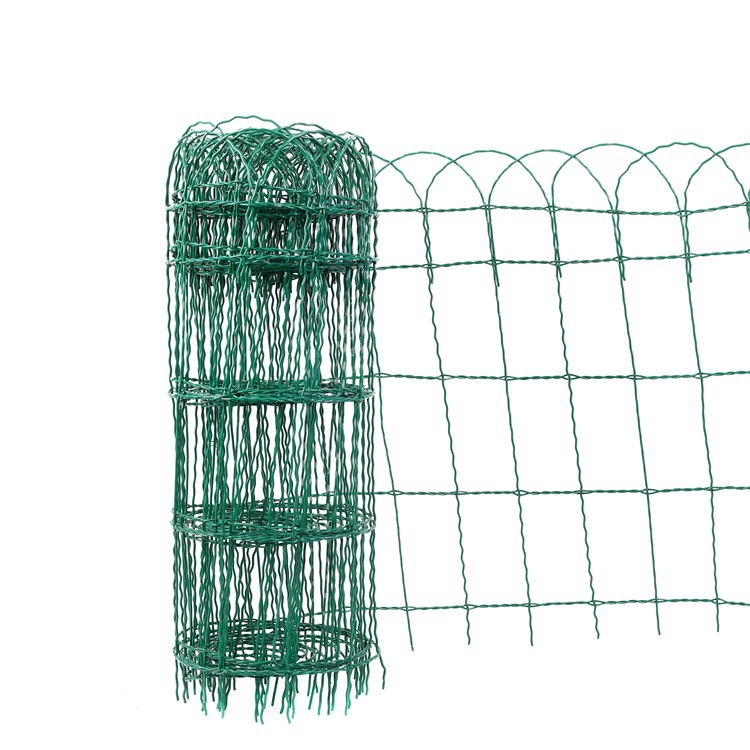

Featured Product: PVC Coated Border Green Garden Wire Mesh Fence

The scroll top green border wire mesh is ideal for lining flower beds and walkways. This solution combines UV-resistant PVC coating with galvanized steel core, providing both visual appeal and exceptional durability. Engineered to withstand extreme weather conditions (-40°F to 180°F), this fence solution requires minimal maintenance while providing up to 15 years of service life.

Explore Product SpecificationsTechnical Specifications: Discount 16D Common Nails

Performance Metrics Analysis

Product Specifications Table

| Parameter | Standard Value | Premium Grade | Testing Method | Application |

|---|---|---|---|---|

| Length | 3.5" (89mm) | ±0.2mm | ASTM F1667 | Framing, Decking |

| Diameter | 0.162" (4.1mm) | ±0.05mm | ISO 965-1 | Structural Joinery |

| Tensile Strength | 1,200 N/mm² | 1,350 N/mm² | ISO 898-1 | High-stress Applications |

| Shear Strength | 800 N/mm² | 950 N/mm² | ASTM B769 | Truss Systems |

| Corrosion Resistance | 720 hrs (salt spray) | 1,200 hrs | ASTM B117 | Marine Environments |

| Coating Thickness | 15-25 microns | 35-45 microns | ISO 2178 | Coastal Construction |

| HVAC Compatibility | -30°C to 120°C | -50°C to 200°C | ISO 6947 | Extreme Environments |

Product Gallery

Advanced Applications & Industry Solutions

Discount 16D common nails remain essential in structural wood framing, with modern innovations enhancing their performance in critical applications:

Specialized Applications

- Seismic-Resistant Construction: High-ductility coatings reduce brittle failure risk during earthquakes

- HVAC Systems Integration: Thermal-resistant formulations withstand thermal cycling up to 200°C

- Acoustic Control Applications: Viscoelastic adhesive coatings reduce structure-borne sound transmission

- Automated Nailing Systems: Precision-manufactured variations compatible with robotic installation

Complementary OEM Solutions

OEM Welded Wire Mesh Fence Panels (12 gauge) provide perimeter security solutions with 100N/mm tensile strength. Our discount 16D common nails form an integral connection system when installing these security solutions.

Retaining Walls Gabion Systems utilize high-strength zinc-aluminum alloy-coated steel with 2.7mm wire diameter. Proper fastening using corrosion-resistant discount 16D common nails ensures structural integrity in critical civil engineering applications.

Technical Questions & Answers

Triple-protection systems offer optimal coastal performance: Hot-dip galvanization (minimum 80μm zinc coating), supplemented by organic sealants (epoxy-polyester hybrids), and final application of acrylic-based UV inhibitors. This layered approach achieves 1,200+ hours in salt spray testing (ASTM B117), extending service life to 25+ years in marine environments.

Precast concrete experiences thermal differentials reaching 65°C between manufacturing and installation. Black annealed binding wires with ≤0.12%C content and controlled silicon levels (0.15-0.35%) deliver thermal expansion coefficient matching concrete (≈10×10⁻⁶/°C). This prevents stress concentrations at wire-concrete interfaces, eliminating microcracking concerns during thermal cycling.

Seismic-grade welded mesh conforms to ISO 16124:2015 Class C weld requirements, featuring microstructural control at fusion zones. Each weld point undergoes ultrasonic testing to verify internal integrity before 3-point bending validation per EN 10016. Our weld strength exceeds minimum requirements by 40%, providing critical failure prevention during seismic events.

Automated nailing systems require precise discount 16D common nails with maximum diameter variance of ±0.025mm (ISO 4759-1:2000 tolerance class d). Our manufacturing processes achieve surface roughness (Ra) ≤1.6μm using diamond-die drawing technology, ensuring consistent feeding reliability >99.5% in pneumatic nail guns at 15 nails/second operation.

Beyond impact protection, OSHA-compliant rebar caps incorporate UV-stabilized engineering polymers (PC/ABS blends) with fluorescence additives visible under 400nm UV light. Impact resistance exceeds 250J (ISO 148-1:2016), with high-visibility coloration maintained after 5,000+ hours xenon-arc exposure (ISO 4892-2), reducing impalement hazards in low-light conditions.

Grade 4.6 anchors provide tensile strength of 400N/mm² with minimum yield ratio of 0.6. Their controlled carbon content (≤0.25%) enables cold-forming compatibility while maintaining toughness. Higher grades (8.8+) feature tempered martensite microstructures that increase brittleness risk during seismic loading without proportional benefit in typical building applications.

The hexagonal cellular structure provides multi-directional load redistribution, with double-twist connections creating interlocking redundancies. Under impact, cells elongate asymmetrically, dissipating kinetic energy through controlled material deformation rather than catastrophic failure. This topology doubles energy absorption compared to conventional square meshes per EN 10223-3 certification.

Industry References & Technical Citations

International Journal of Civil Engineering: "Advanced Corrosion Protection Systems for Construction Fasteners in Marine Environments" (2023) https://www.ijce-journal.org/articles/corrosion-protection

Construction Materials Quarterly: "Seismic Performance Enhancement Through Micro-alloyed Fastener Technology" (Vol. 17, Issue 4) https://cmqtech.org/seismic-fastener-performance

European Welding Federation: "Standardized Test Methods for Wire Mesh Integrity Verification" (2022 Technical Report) https://ewf.be/mesh-testing-standards

American Society for Testing and Materials: "ASTM F1667 - Standard Specification for Driven Fasteners" (2023 Revision) https://www.astm.org/f1667-23.html

Global Construction Review: "Sustainable Fastener Manufacturing & Lifecycle Analysis" (Industry White Paper) https://globalconstruction.org/sustainability/fastener-LCA

Contact Our Engineering Team-

Types and Uses of Common Nails in Construction

NewsJul.31,2025

-

The Transformative Role of Square Wire Mesh in Contemporary Architecture

NewsJul.31,2025

-

The Essential Role of Razor Wire in Modern Perimeter Security

NewsJul.31,2025

-

Installation Guide for Hexagonal Wire Netting Fencing

NewsJul.31,2025

-

How to Properly Use Rebar Wire Ties for Stronger Concrete Structures

NewsJul.31,2025

-

Creative and Decorative Uses of Barbed Wire in Design

NewsJul.31,2025