Explore Leading Sleeve Anchor Bolt Manufacturers in the Industry Today

The Importance of Sleeve Anchor Bolt Factories in Construction

In the realm of construction and engineering, the choice of fastening systems significantly influences the durability and safety of structures. Among the essential fastening solutions, sleeve anchor bolts stand out for their versatility and reliability. This article explores the significance of sleeve anchor bolt factories, their manufacturing processes, and their role in the construction industry.

What Are Sleeve Anchor Bolts?

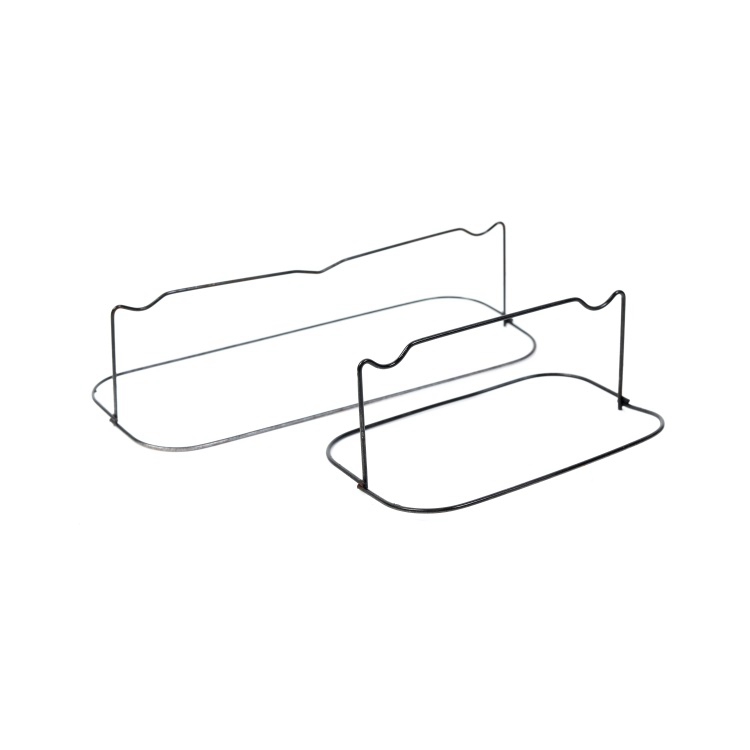

Sleeve anchor bolts are specialized fasteners designed to attach objects to concrete and masonry surfaces. They consist of a threaded bolt with an attached sleeve, which expands upon installation, securely anchoring the bolt into the substrate. This unique expansion mechanism allows sleeve anchors to provide a strong hold in various applications, from securing handrails and shelving to attaching machinery and structural components. Their capacity to bear heavy loads while withstanding tension and shear forces makes them a popular choice among contractors and engineers.

The Role of Sleeve Anchor Bolt Factories

Sleeve anchor bolt factories play a vital role in ensuring that these critical components are manufactured to industry standards. They are responsible for producing high-quality anchors that meet the demands of modern construction projects. These factories employ advanced manufacturing techniques, including forging, machining, and heat treatment, to create products that offer exceptional strength and corrosion resistance.

1. Quality Control Factories often implement stringent quality control measures throughout the production process. This includes testing the tensile strength, dimensional accuracy, and expansion characteristics of the anchors. By adhering to recognized standards, such as ASTM (American Society for Testing and Materials) specifications, these factories ensure that their products are reliable and can withstand the demands of various environmental conditions.

sleeve anchor bolt factories

2. Material Selection The materials used in the production of sleeve anchor bolts significantly impact their performance. Factories typically use high-strength steel, along with coatings like zinc plating or hot-dip galvanization, to enhance corrosion resistance. Such material choices ensure that sleeve anchors can endure exposure to moisture, chemicals, and other harsh conditions present in construction environments.

3. Customization Sleeve anchor bolt factories often offer customization options to accommodate specific project requirements. This could include variations in size, thread type, or even specialized coatings. Such flexibility allows engineers and contractors to select the right anchor for their particular applications, which is crucial for ensuring safety and performance.

4. Research and Development Many factories invest in research and development to innovate and improve their products continually. By exploring new materials and manufacturing techniques, they can develop advanced sleeve anchors with enhanced performance characteristics. This commitment to innovation ensures that the industry can adapt to evolving engineering challenges and standards.

The Impact on Construction Projects

The availability of high-quality sleeve anchor bolts from reputable factories has a direct impact on the success of construction projects. Reliable sleeve anchors improve the integrity of structures, reduce the risk of failures, and contribute to overall project safety. Moreover, when construction teams can source well-manufactured components, they can streamline their processes, minimize delays, and achieve better project timelines.

Conclusion

In summary, sleeve anchor bolt factories are indispensable in the construction industry, providing essential fastening solutions that ensure the safety and durability of structures. Through advanced manufacturing processes, stringent quality control, and a commitment to research and development, these factories supply high-quality components that meet the rigorous demands of modern engineering projects. As construction practices continue to evolve, the role of sleeve anchor bolts and their manufacturers will remain central to building safe and reliable infrastructures worldwide.

-

The Durability and Versatility of Steel Wire

NewsJun.26,2025

-

The Best Iron Nails for Your Construction Projects

NewsJun.26,2025

-

Strengthen Your Projects with Durable Metal Stakes

NewsJun.26,2025

-

Get the Job Done Right with Duplex Nails

NewsJun.26,2025

-

Explore the Versatility and Strength of Metal Mesh

NewsJun.26,2025

-

Enhance Your Security with Razor Wire

NewsJun.26,2025