Discount 16d Common Nails - Affordable & Durable Deals

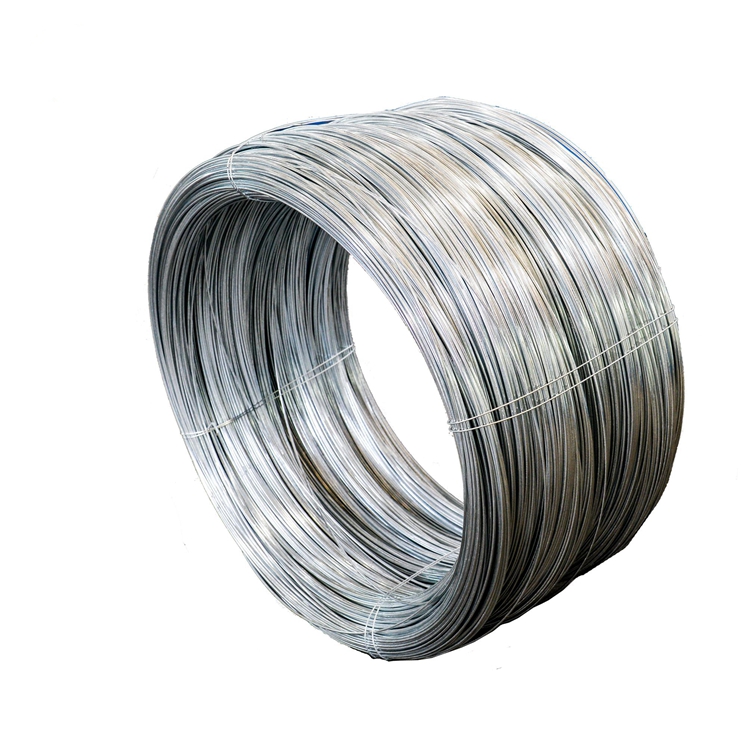

Featured Product: Hot Dipped Galvanized Steel Wire

Industry Trends & Market Overview: Discount 16 d Common Nails & Related Products

The global discount 16 d common nails and wire mesh market is projected to reach USD 7.5 billion by 2027, driven by increasing infrastructure development, stricter building codes, and demand for corrosion-resistant fastening solutions. With heightened requirements in petrochemical, metallurgy, construction, and mining sectors, products like discount 16 d common nails and OEM wire mesh solutions are evolving in design, material, and manufacturing standards.

- Growing Infrastructure Investment:China and the US lead increased consumption of heavy-duty nails, mesh, and fastening accessories.

- Green & Sustainable Materials:Rise in demand for galvanization (hot-dip) and recycled steel content due to sustainable construction mandates.

- Enhanced Regulatory Compliance:Adoption of ISO 898-1, ASTM F1667, EN10244, and related standards in production and inspection processes across top manufacturers.

What Are Discount 16 d Common Nails? - Core Specifications Table

| Parameter | Typical Value | Industry Standard | Relevance |

|---|---|---|---|

| Nail Length | 3.5 inches (89 mm) | ASTM F1667 | Frame/Timber Jointing |

| Diameter | 0.148 inches (3.76 mm) | ANSI B18.6.1 | Strength & Load Capacity |

| Finish | Hot Dipped Galvanized | EN10244-2 | Corrosion Resistance |

| Shank Type | Smooth or Ringed | ASTM F1667 | Withdrawal Resistance |

| Material | Q195/Q235 Low Carbon Steel | ISO 898-1 | Durability & Performance |

| Coating Thickness | ≥ 50 µm (Avg.) | EN ISO 1461 | Anti-rust Capability |

Manufacturing Process of Discount 16 d Common Nails

1. Raw Wire Rod Selection

- High-purity low carbon steel (Q195/Q235)

- Quality checked for content and impurities

2. Wire Drawing

- Drawn to precise diameter (±0.02mm tolerance)

- Continuous monitoring of tensile strength

3. Nail Forming & Heading

- CNC heading for uniform heads

- Automated shank cutting and tip forming

4. Galvanization

- Hot-dip process (per EN10244-2/ISO1461)

- Zinc coating ≥50µm for rust protection

5. Inspection & Packaging

- 100% batch mechanical and anti-corrosion tests

- ISO certified documentation

Technical Parameters of Hot Dipped Galvanized Steel Wire

| Parameter | Value Range | Typical Standard | Test Method |

|---|---|---|---|

| Diameter | 0.90 - 5.00 mm | EN10244-2 | Micrometer |

| Zinc Coating | 40 - 250 g/m² | ISO 1461 | Gravimetric |

| Tensile Strength | 350 - 600 N/mm² | EN50189 | Tensile Machine |

| Elongation | ≥10% | ISO 6892-1 | Elongation Test |

| Surface Quality | Glossy, No Porosity | Visual/SEM | Microscopy |

| Corrosion Test (Salt Spray) | >720 hrs no red rust | ASTM B117 | Salt Spray Cabinet |

Figure 1: Technical parameter comparison of Hot Dipped Galvanized Steel Wire vs. industry average.

Application Scenarios & Technical Advantages

Building & Civil Engineering: discount 16 d common nails are the anchor of timber frame, pallet assembly, and formwork, promoting superior withdrawal resistance and enhanced corrosion protection as per EN10244-2.

Mining Operations: OEM welded wire mesh for underground mines secures rock face, tunnel arch lining, and shotcrete reinforcement—offering tensile strength above 420N/mm² and elongation over 10% for safety.

Flood Control & Landscaping: OEM retaining walls gabion, manufactured from hot-dipped galvanized wire, withstands harsh river environment, delivering a service life of 25-30 years in open field applications.

Manufacturer Comparison Table (2024): OEM Mesh & Nail Solutions

| Manufacturer | Main Products | Certifications | MOQ | Lead Time | Core Advantage |

|---|---|---|---|---|---|

| Five Star Metal | discount 16 d common nails, OEM mesh, gabion |

ISO 9001, EN10244 | 1 ton | 7-20 days | Customization, strict QC, fast delivery |

| Xinxing Steel | OEM anchor bolt grade 4.6, welded mesh |

CE, ISO 14001 | 5 tons | 15-30 days | Eco-friendly process |

| Hebei MeshPro | oem cap mushroom, black annealed binding wire |

ISO 9001, SGS | 3-5 tons | 10-25 days | Cost-effectiveness |

Figure 2: Distribution of primary OEM fastener & mesh shipments by product category (2023–24, by tonnage).

Customization Solutions: Five Star Metal OEM Capabilities

Discount 16 d common nails and related wire-mesh products can be tailored in diameter, shank design, finish, packaging, and mechanical properties. The OEM process includes technical drawing review, prototype sampling, performance testing (per ISO/ASTM), and final batch QC with certificates. Significant customization is also available for:

- Mesh Size: Hexagonal (1", 1.5", 2"), Square (1"x1", 2"x2"), Gabion (up to 4m length)

- Coating: Heavy zinc, PVC, powder, or black annealed finishes

- Strength: Option for EN10244-2 or ISO 898-1 compliant grades

- Accessories: Custom tie tools, anchor bolt grades 4.6 to 8.8, cap mushrooms, and retaining wall mesh

Technical support includes engineering drawing assistance and on-site application guidance.

Contact for tailored solutions.

Figure 3: Export volume of hot dipped galvanized steel wire by Five Star Metal vs. industry average (2019–2023).

Real-World Case Studies & User Experience

Five Star Metal supplied 800 tons of discount 16 d common nails for turbine platform assembly and 420 tons of oem square welded mesh. After 20 months in severe alkali/corrosive conditions, performance evaluations indicated a rust rate under 8% (per ASTM G85), outperforming previous procurement by >20% reduction in maintenance frequency.

Case 2: Mexico Underground Mines

OEM welded wire mesh achieved zero breakage in over 2,000 reinforcement points. Client feedback (Mining Engineer Carlos Ruiz): "Mesh delivered by Five Star Metal provided better safety margins, ease of handling, and visible surface integrity compared to our previous suppliers."

Case 3: Middle East Oil Refinery

Both oem cap mushrooms and binding wire black annealed passed rigorous ISO/EN field inspections, enduring >750 hours salt mist with full client acceptance. Project engineers highlighted technical support and prompt delivery as key success factors.

Professional FAQ: Discount 16 d Common Nails & Mesh Systems

Q1: What is the standard material for discount 16 d common nails?

A: Top-grade Q195/Q235 low carbon steel, ensuring strength and ductility, sometimes with alloy enhancements for bespoke requirements.

Q2: What anti-corrosion standards are followed?

A: Products are galvanized per EN10244-2 and ISO1461. Salt spray resistance typically exceeds 720 hours (ASTM B117), suitable for exposed or marine environments.

Q3: How is OEM anchor bolt grade 4.6 defined?

A: Grade 4.6 refers to 400MPa nominal tensile strength, 60% yield ratio per ISO898-1, widely used for structural connections in precast concrete and steel fabrications.

Q4: What installation standards should be followed?

A: Nail and mesh installation adheres to ANSI B18.6.1, local building codes, and for mesh/gabion installation, ASTM A975/A975M is recommended.

Q5: What is black annealed binding wire, and where is it used?

A: Annealed at 900°C for softness and malleability; extensively used for tying reinforcement bars, mesh, and in horticulture. Conforms to ISO 16120-2.

Q6: What is the OEM welded mesh fence panel in 12 gauge?

A: Typically 2.5mm (12G) galvanized wire welded to form robust, anti-intrusion barriers for security and livestock fencing. Common panel sizes are 2.4x1.8m.

Q7: What is the lifespan of hot dipped galvanized steel wire products?

A: In typical outdoor or aggressive chemical settings, service life is 20–30 years. Maintenance schedules (as per EN206) further improve lifespan.

Delivery Timeline, Quality Assurance & Client Support

- Lead Time: 7–20 days for standard sizes, 15–30 days for bespoke projects

- Warranty: 36-month product replacement/defect guarantee

- Certification: All products delivered with ISO 9001:2015, EN10244-2/ISO1461 test reports, material traceability, and third-party inspection available

- Support: 24/7 technical response line & on-site engineering consultation for OEM projects

Expert Quotes & References

“Adoption of advanced hot-dip galvanizing and CNC forming has raised the standard for industrial nails and mesh, markedly reducing maintenance cycles and enhancing lifetime ROI.”

— Construction Materials Journal

Further Reading & References:

[Product Details]

| [Corrosion Performance Study]

| [Industry Forum Discussion]

| [ASTM F1667 Standard]

-

Types and Uses of Common Nails in Construction

NewsJul.31,2025

-

The Transformative Role of Square Wire Mesh in Contemporary Architecture

NewsJul.31,2025

-

The Essential Role of Razor Wire in Modern Perimeter Security

NewsJul.31,2025

-

Installation Guide for Hexagonal Wire Netting Fencing

NewsJul.31,2025

-

How to Properly Use Rebar Wire Ties for Stronger Concrete Structures

NewsJul.31,2025

-

Creative and Decorative Uses of Barbed Wire in Design

NewsJul.31,2025