custom black annealed binding iron wire bwg 28

The Versatile Applications of Custom Black Annealed Binding Iron Wire (BWG 28)

In the realm of industrial materials and construction, the importance of high-quality binding wires cannot be overstated. Among these, custom black annealed binding iron wire with a wire gauge (BWG) of 28 has emerged as a popular choice among professionals in various fields. This article explores the properties, manufacturing process, and diverse applications of this essential product.

Properties of Black Annealed Binding Iron Wire

Black annealed binding iron wire is known for its unique combination of strength, flexibility, and durability. The “black” in its name refers to the wire’s surface finish, which is a result of the annealing process. This process involves heating the wire to a specific temperature and then allowing it to cool slowly, which helps to relieve internal stresses and increase ductility.

With a wire gauge of 28, this particular type of wire has a diameter of approximately 0.0126 inches or 0.324 mm, making it relatively thin yet robust enough for various binding applications. The annealing process not only enhances its mechanical properties but also provides a level of protection against corrosion, even though it is not entirely rustproof. This feature is particularly beneficial for applications where the wire may be exposed to outdoor elements.

Manufacturing Process

The manufacturing of custom black annealed binding iron wire involves several stages. Initially, raw steel wire is drawn to the desired thickness. This drawn wire is then subjected to a heat treatment process, which involves heating it in a controlled environment to ensure uniform temperature distribution. After this, the wire is allowed to cool gradually, resulting in the blackened finish characteristic of annealed wire.

During the production process, manufacturers can customize the wire based on client specifications, including length and tensile strength. This capability enables wide-ranging applications, making it suitable for numerous industries.

Applications of Binding Iron Wire

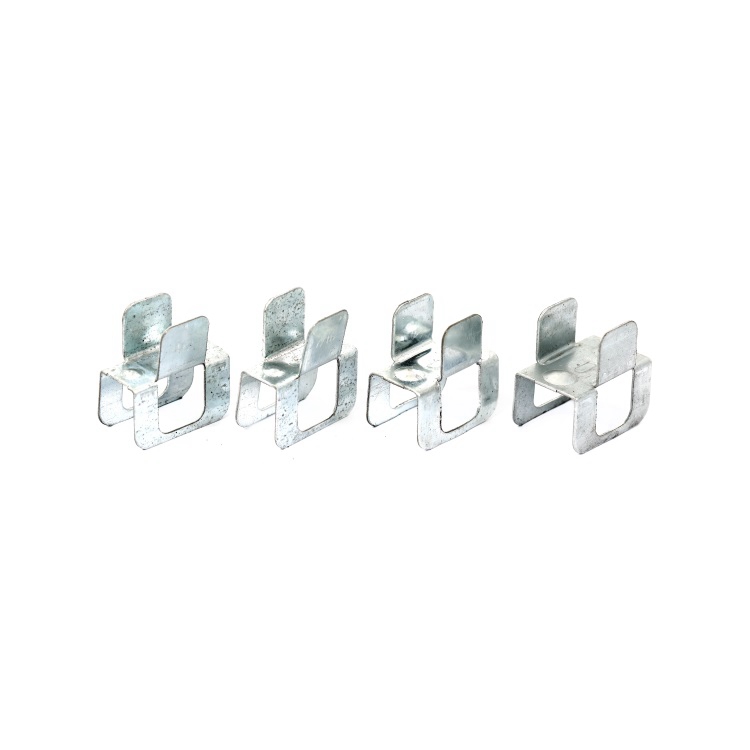

custom black annealed binding iron wire bwg 28

The versatility of custom black annealed binding iron wire makes it an essential tool in various sectors

. Here are some of its common applications1. Construction In the construction industry, this wire is often used for tying rebar together to form reinforced concrete structures. Its flexibility allows for easy manipulation and secure binding, which is crucial for structural integrity.

2. Agriculture Farmers frequently utilize binding wire for securing fencing, tying plants, and bundling hay. The wire’s durability and resistance to breakage make it an ideal choice for outdoor agricultural applications.

3. Crafts and DIY Projects Home improvement enthusiasts and crafters often rely on black annealed wire for making decorative items, building frameworks, or creating sculptures. Its pliability allows for intricate designs and crafting possibilities.

4. Manufacturing In various manufacturing processes, binding wire serves as a component for assemblies and packaging. It is commonly used to bundle products together for shipping and transport.

5. Electrical Work The wire’s conductivity makes it suitable for some electrical applications, including grounding and supporting electrical systems.

Conclusion

Custom black annealed binding iron wire (BWG 28) is a testament to the intersection of versatility, strength, and practicality in industrial materials. Its combination of properties allows it to meet the demands of various applications, ranging from construction to agriculture and crafts. As industries continue to grow and evolve, the significance of such materials will undoubtedly endure, spotlighting the indispensable role they play in everyday operations and projects.

-

The Durability and Versatility of Steel Wire

NewsJun.26,2025

-

The Best Iron Nails for Your Construction Projects

NewsJun.26,2025

-

Strengthen Your Projects with Durable Metal Stakes

NewsJun.26,2025

-

Get the Job Done Right with Duplex Nails

NewsJun.26,2025

-

Explore the Versatility and Strength of Metal Mesh

NewsJun.26,2025

-

Enhance Your Security with Razor Wire

NewsJun.26,2025