annealed binding tie wire factories

The Importance of Annealed Binding Tie Wire Factories

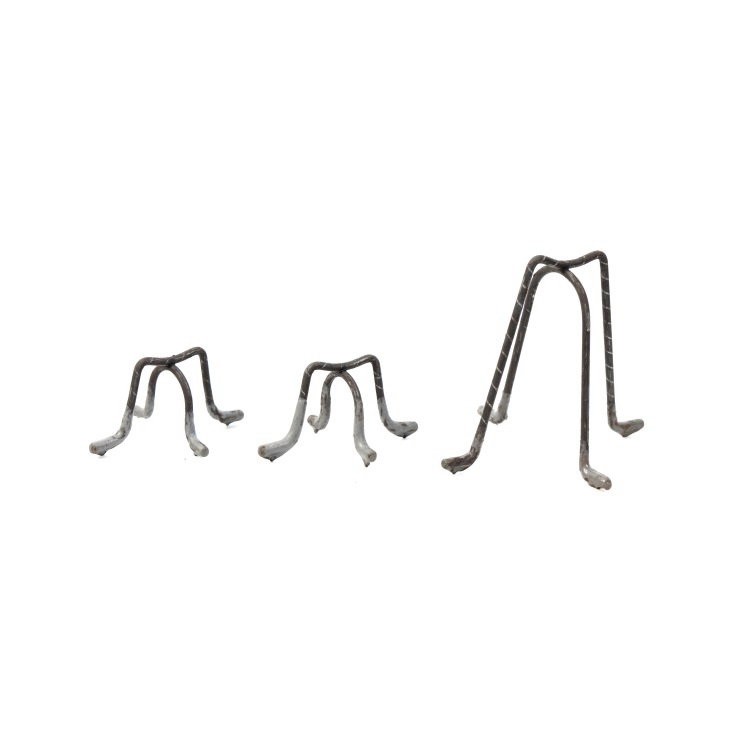

In the construction and manufacturing industries, the significance of high-quality materials cannot be overstated. Among these materials, annealed binding tie wire plays a crucial role, especially in functions requiring strong and durable binding solutions. Annealed tie wire is widely used for tying, bundling, and securing various components in construction and industrial projects, making it a staple product in various sectors.

The Importance of Annealed Binding Tie Wire Factories

The manufacturing process of annealed tie wire begins with sourcing high-quality raw materials, typically low-carbon steel. This ensures that the final product possesses both strength and flexibility. Once the raw material is procured, it undergoes several stages, including cleaning, drawing, and annealing. Each step is crucial as it affects the wire's mechanical properties and overall quality. Factories specializing in annealed binding tie wire often employ advanced machinery and technology to ensure consistency and precision in their production processes.

annealed binding tie wire factories

One of the advantages of specialized factories in producing annealed binding tie wire is their ability to meet diverse customer needs. These factories can produce wire in varying diameters, coil weights, and lengths, catering to specific requirements across different industries. Whether it's for large-scale construction projects or smaller, specialized applications, the flexibility of tie wire production makes it an indispensable resource.

Moreover, operations in these factories prioritize quality control at every stage of the manufacturing process. Rigorous testing and inspection methods are employed to ensure that the wire meets industry standards and customer expectations. This focus on quality not only enhances the durability of the wire but also reduces the likelihood of failures or accidents on-site, which can lead to costly delays and safety hazards.

The demand for annealed binding tie wire has grown steadily due to its versatility and durability. Applications are extensive, including tying rebar in concrete construction, bundling wires in electrical projects, and securing various materials in packaging industries. The increasing trend towards construction automation also drives the need for reliable binding materials, ensuring that annealed tie wire factories continue to operate at the forefront of innovation.

In conclusion, annealed binding tie wire factories play a pivotal role in supporting the construction and manufacturing industries. By producing high-quality, flexible, and durable wire, these specialized factories fulfill essential requirements for various binding applications. Their commitment to quality, versatility, and customer satisfaction makes them vital contributors to the smooth operation of numerous projects. As industries continue to evolve and expand, the relevance of annealed binding tie wire is set to grow, reflecting the ongoing demand for materials that facilitate efficiency and safety in construction.

-

Transform Your Outdoor Spaces with High-Quality Gabions

NewsJul.23,2025

-

The Power and Versatility of Wire Mesh for Your Projects

NewsJul.23,2025

-

The Complete Guide to Annealed Wire

NewsJul.23,2025

-

Pallet Nails--The Essential Fastener for Pallet Construction

NewsJul.23,2025

-

Anchor Bolt Analysis: A Key Component to Ensure Building Stability

NewsJul.23,2025

-

Enhance Your Property Security with Quality Barbed Wire

NewsJul.23,2025