sij . 20, 2025 04:10

Back to list

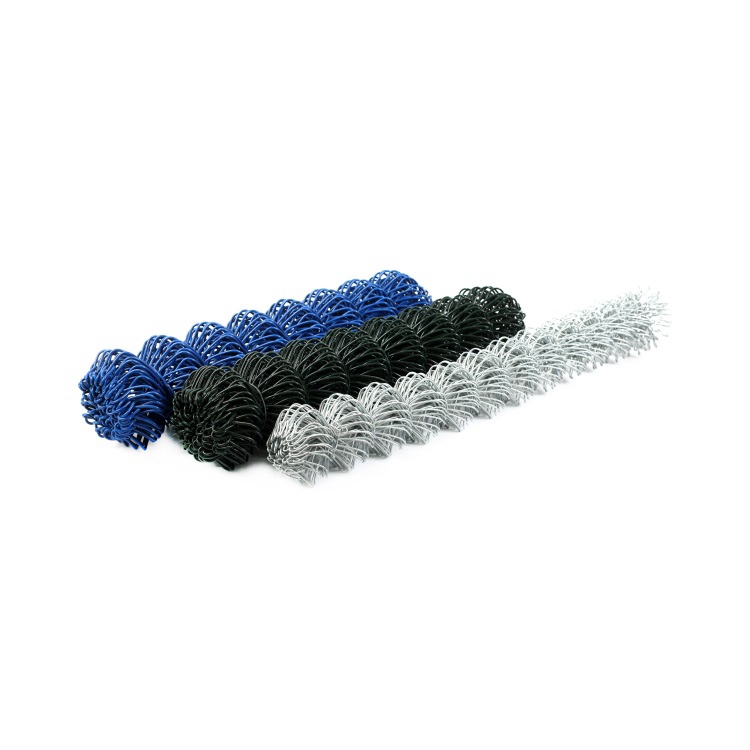

Hot dipped galvanized steel wire

In the realm of construction and manufacturing, selecting the right materials is crucial for the project's success. One such essential material is the 18 gauge black annealed binding wire. This versatile product plays a vital role in a wide variety of applications, ranging from construction to agricultural use. Understanding its characteristics, benefits, and applications can significantly enhance the quality and efficiency of your projects.

Authoritativeness in the use of binding wire is demonstrated through adherence to industry standards and understanding the specific needs of each project. Expert users of 18 gauge black annealed wire endorse it for its consistency and dependability. These qualities ensure that it meets the rigorous demands found in both urban and rural applications. Additionally, when sourced from reputable manufacturers, these wires are produced under strict quality controls, ensuring uniformity in each roll or coil provided. Trustworthiness in using 18 gauge black annealed binding wire is established through its track record in various applications. Professionals who have incorporated this binding wire into their work consistently report satisfaction with its performance. Its affordability, coupled with robust functionality, means that it remains a trusted choice for seasoned contractors, construction managers, and agricultural specialists alike. For optimal results, selecting the right supplier is crucial. A good supplier will offer clear information about the production process, guarantees of quality, and compliance with relevant standards and regulations. Establishing a relationship with a credible supplier not only ensures the best materials but also offers peace of mind that the wire will perform as expected. In conclusion, 18 gauge black annealed binding wire stands as an exemplary product combining flexibility, strength, and reliability. Its wide range of applications across various industries underscores its versatility. As professionals continue to seek materials that balance cost-effectiveness with performance excellence, 18 gauge black annealed binding wire remains an unrivaled component in the toolbox of constructors and agriculturalists. Trust, expertise, and authoritative usage back its reputation as a go-to solution for binding and securing needs.

Authoritativeness in the use of binding wire is demonstrated through adherence to industry standards and understanding the specific needs of each project. Expert users of 18 gauge black annealed wire endorse it for its consistency and dependability. These qualities ensure that it meets the rigorous demands found in both urban and rural applications. Additionally, when sourced from reputable manufacturers, these wires are produced under strict quality controls, ensuring uniformity in each roll or coil provided. Trustworthiness in using 18 gauge black annealed binding wire is established through its track record in various applications. Professionals who have incorporated this binding wire into their work consistently report satisfaction with its performance. Its affordability, coupled with robust functionality, means that it remains a trusted choice for seasoned contractors, construction managers, and agricultural specialists alike. For optimal results, selecting the right supplier is crucial. A good supplier will offer clear information about the production process, guarantees of quality, and compliance with relevant standards and regulations. Establishing a relationship with a credible supplier not only ensures the best materials but also offers peace of mind that the wire will perform as expected. In conclusion, 18 gauge black annealed binding wire stands as an exemplary product combining flexibility, strength, and reliability. Its wide range of applications across various industries underscores its versatility. As professionals continue to seek materials that balance cost-effectiveness with performance excellence, 18 gauge black annealed binding wire remains an unrivaled component in the toolbox of constructors and agriculturalists. Trust, expertise, and authoritative usage back its reputation as a go-to solution for binding and securing needs.

Share

Latest news

-

Types and Uses of Common Nails in Construction

NewsJul.31,2025

-

The Transformative Role of Square Wire Mesh in Contemporary Architecture

NewsJul.31,2025

-

The Essential Role of Razor Wire in Modern Perimeter Security

NewsJul.31,2025

-

Installation Guide for Hexagonal Wire Netting Fencing

NewsJul.31,2025

-

How to Properly Use Rebar Wire Ties for Stronger Concrete Structures

NewsJul.31,2025

-

Creative and Decorative Uses of Barbed Wire in Design

NewsJul.31,2025