Fév . 13, 2025 08:57

Back to list

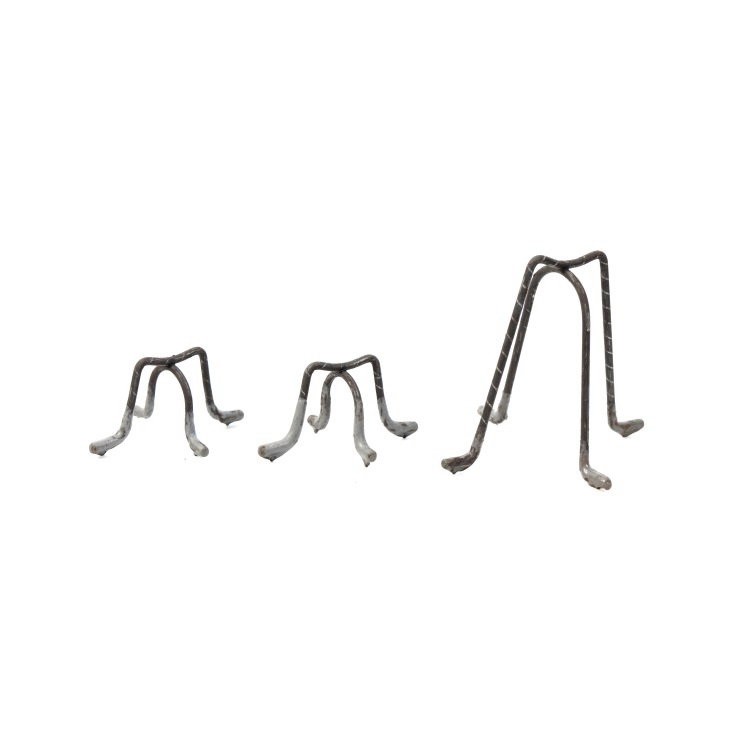

square hole welded wire mesh

Square hole welded wire mesh is an indispensable component in multiple industries, thanks to its versatility, strength, and reliability. As an SEO content strategist with years of experience, I can affirm that understanding the nuances of this product not only enhances the purchasing journey for professionals but also aids suppliers in showcasing their solutions effectively.

Safety standards and regulatory compliance are non-negotiable elements in the production and deployment of square hole welded wire mesh. Reputable manufacturers adhere to stringent guidelines and certification processes, ensuring that the mesh meets all necessary local and international standards. This compliance guarantees not only product performance but also safety and environmental responsibility. Clients and contractors prioritizing long-term investments appreciate the cost-efficiency that square hole welded wire mesh offers. Despite its initial investment, the mesh’s durability and maintenance-free nature result in significant cost savings over time, reducing the need for replacements and repairs. Furthermore, its installation process is relatively straightforward compared to other materials, potentially decreasing labor costs and project timelines, which are crucial considerations for large-scale projects. It's worth noting that the choice of square hole welded wire mesh goes beyond technical specifications and extends into considerations of supplier trustworthiness. Establishing a reputable network of suppliers involves verifying their track record, customer testimonials, and industry certifications. For end-users, this translates to purchasing from vendors known for their quality assurance and post-sale support, ensuring that their investment is sound and their expectations met. In conclusion, square hole welded wire mesh is not just a product but a strategic solution that integrates engineering excellence with industrial application needs. Its significance in reinforcing structures, safeguarding agriculture, and providing versatile fabrication options makes it a dynamic product that adapts seamlessly to a spectrum of applications. Awareness and continuous education in such products are essential, empowering professionals to make informed purchasing decisions and optimize their operational efficiency through robust, efficient, and reliable materials.

Safety standards and regulatory compliance are non-negotiable elements in the production and deployment of square hole welded wire mesh. Reputable manufacturers adhere to stringent guidelines and certification processes, ensuring that the mesh meets all necessary local and international standards. This compliance guarantees not only product performance but also safety and environmental responsibility. Clients and contractors prioritizing long-term investments appreciate the cost-efficiency that square hole welded wire mesh offers. Despite its initial investment, the mesh’s durability and maintenance-free nature result in significant cost savings over time, reducing the need for replacements and repairs. Furthermore, its installation process is relatively straightforward compared to other materials, potentially decreasing labor costs and project timelines, which are crucial considerations for large-scale projects. It's worth noting that the choice of square hole welded wire mesh goes beyond technical specifications and extends into considerations of supplier trustworthiness. Establishing a reputable network of suppliers involves verifying their track record, customer testimonials, and industry certifications. For end-users, this translates to purchasing from vendors known for their quality assurance and post-sale support, ensuring that their investment is sound and their expectations met. In conclusion, square hole welded wire mesh is not just a product but a strategic solution that integrates engineering excellence with industrial application needs. Its significance in reinforcing structures, safeguarding agriculture, and providing versatile fabrication options makes it a dynamic product that adapts seamlessly to a spectrum of applications. Awareness and continuous education in such products are essential, empowering professionals to make informed purchasing decisions and optimize their operational efficiency through robust, efficient, and reliable materials.

Share

Latest news

-

The Ultimate Guide to Premium Quality Field Fence Solutions

NewsAug.12,2025

-

The Essential Guide to Premium Square Wire Mesh Solutions

NewsAug.12,2025

-

The Essential Guide to Hexagonal Wire Netting Farm Fencing

NewsAug.12,2025

-

Premium Continuous Deck Rail Slab Bolster Solutions

NewsAug.12,2025

-

High-Performance Aluminum Tie Wire Reel for Construction Applications

NewsAug.12,2025

-

Crafted Premium Galvanized Hexagonal Gabion Wire Mesh Solutions

NewsAug.12,2025