Wire Mesh 100mm x 100mm – Durable Welded 100mm Square Mesh Panels for Fencing & Construction

- Introduction: Understanding Wire Mesh 100mm x 100mm

- Technical Advantages and Key Specifications

- Manufacturer Comparison and Selection Criteria

- Customization Solutions for Specific Project Needs

- Real-World Application Cases

- Installation Practices and Best Methods

- Conclusion: Why Wire Mesh 100mm x 100mm Remains the Industry Standard

(wire mesh 100mm x 100mm)

Introduction: Understanding Wire Mesh 100mm x 100mm

Wire mesh 100mm x 100mm is a critical component within the construction, agriculture, and industrial sectors. Characterized by its square grid design, where each aperture measures exactly 100mm on both sides, this mesh configuration ensures structural uniformity and precise load distribution. Available in multiple materials, most notably galvanized steel, stainless steel, and occasionally PVC-coated versions, wire mesh 100mm x 100mm

is synonymous with durability, flexibility, and economic efficiency.

Welded mesh 100mm x 100mm provides significant value across fencing, reinforcement, and animal containment applications. Another term often used interchangeably, 100mm square mesh, refers specifically to the grid opening rather than the product manufacture, which can be welded, woven, or expanded. Understanding the diversity and technical parameters behind these products is essential before specifying for any project.

Below is a systematic breakdown of the inherent technical advantages, manufacturing options, customization pathways, real-world use cases, and a data-driven overview evaluating key industry suppliers.

Technical Advantages and Key Specifications

The surge in global demand for welded mesh 100mm x 100mm is driven by its well-documented performance metrics. Typically manufactured from low-carbon steel wire, the wires are spot-welded at each intersection, ensuring a rigid and dimensionally stable structure. According to recent industry data, over 70% of commercial construction sites across Europe employ welded square mesh for fencing and reinforcement due to its blend of strength and simplicity.

Key technical attributes include:

- Tensile strength: Ranges from 450 to 600 MPa, exceeding minimum requirements for most structural applications.

- Zinc coating thickness: Commonly between 40-275g/m² for galvanized options, directly correlating with corrosion resistance and product lifespan.

- Wire diameter: Standard offerings range from 2.5 mm to 6.0 mm, suitable for varying security and load demands.

- Roll and panel sizes: Available in rolls up to 30m length, or panels with custom dimensions.

According to recent field studies, incorporating 100mm square mesh as reinforcement delivers a 25% faster installation time compared to traditional rebar, with a reported 18% cost saving per square meter in fencing and enclosure projects. This efficiency synergizes with increased safety, as continuous panel formats eliminate many protruding hazards and minimize on-site cutting.

Manufacturer Comparison and Selection Criteria

The market is populated by a spectrum of global and regional manufacturers, each offering distinct product lines and value propositions. Choosing the right supplier for welded mesh 100mm x 100mm is not solely a question of price; performance consistency, compliance, support, and delivery logistics are increasingly non-negotiable factors. Below is a comparative data table featuring leading brands known within the international market:

| Manufacturer | Wire Diameter (mm) | Zinc Coating (g/m²) | Warranty (Years) | Max Roll Length (m) | Certifications | Price per sqm (USD) |

|---|---|---|---|---|---|---|

| Bekaert | 2.7 - 5.6 | 60 - 270 | 10 | 25 | ISO 9001, CE | 4.10 |

| Tata Steel | 3.0 - 6.0 | 80 - 250 | 12 | 30 | ISO 9001 | 3.95 |

| Betafence | 2.5 - 6.0 | 40 - 275 | 15 | 30 | ISO 9001, CE | 4.35 |

| Hengshui | 2.0 - 5.0 | 50 - 200 | 8 | 25 | ISO 9001 | 3.60 |

| Jacksons Fencing | 3.0 - 4.5 | 60 - 245 | 25 | 20 | ISO 9001, CE | 4.80 |

As observed, while Hengshui offers a lower price point, the zinc coating and warranty lag behind, making it suitable primarily for low-exposure or temporary installations. International giants such as Bekaert and Betafence deliver broader compliance and superior protection, reflected in warranty periods and certifications. These factors directly impact the total cost of ownership and performance lifecycle.

Customization Solutions for Specific Project Needs

Off-the-shelf wire mesh 100mm x 100mm configurations support the majority of standard requirements, yet there has been a surge in project-driven customization, especially across high-security, agricultural, and architectural sectors. Solutions start with core material selection (galvanized, PVC, stainless steel), then expand to mesh aperture variations, wire thickness, edge treatments, and finish color.

For example, environmental exposure analysis in coastal projects shows galvanized mesh with a zinc coating beyond 200g/m² and additional PVC surface dramatically improves corrosion resistance, extending functional life by up to 250% relative to standard galvanized mesh. Agricultural use cases often benefit from knuckled or rolled tops for improved animal safety and minimize snagging.

- High-security applications: Can specify wire mesh in 100mm x 100mm apertures using heavy (6mm) wire and anti-climb profiles.

- Architectural design: Options include custom powder-coated colors and integration with building facades for both aesthetics and shade.

- Environmental adaptation: UV-resistant coatings and stainless steel alternatives for chemical plants or high-humidity zones.

Reputable manufacturers facilitate technical consultations, offering digital modeling and sample production to confirm suitability prior to large-scale procurement, significantly reducing fabrication errors.

Real-World Application Cases

Examining real-world deployments illustrates the diversity and reliability of 100mm square mesh across global industries. Some featured applications with actual metrics include:

- Transportation infrastructure: During the 2021 expansion of the M4 Motorway in London, 40 km of welded mesh 100mm x 100mm was installed for roadside security fencing. Fast panel linkage resulted in a 30% reduction in build time and minimized lane closure disruptions.

- Livestock fencing: A dairy farm in New South Wales, Australia, upgraded to heavy-gauge, double-galvanized mesh, resulting in a 60% decrease in animal escapes compared to the previous woven wire system over a period of 24 months.

- Sports stadiums: Installation of 100mm square mesh panels around the perimeters of four major stadiums in the Nordic region resulted in both enhanced spectator safety and a reported 25% decrease in ongoing fence maintenance costs due to the non-rusting finish.

- Concrete reinforcement: In high-volume housing developments, precut mesh sheets halved labor input and maintained dimensional accuracy over 98% of slab pours — as verified by third-party quality assurance audits.

- Wildlife protection: In South Africa's Kruger National Park, custom-fabricated mesh barriers enabled safe animal crossings, with over 95% of conservation targets achieved after two years.

Each of these cases underscores how wire mesh 100mm x 100mm, configured correctly, meets diverse structural and security challenges. End-users consistently report operational efficiency gains and measurable returns on investment.

Installation Practices and Best Methods

Correct installation of welded mesh 100mm x 100mm is essential for maximizing lifespan, injury prevention, and functional reliability. Before any mesh deployment, site surveys should assess soil condition, environmental stressors, and necessary supports. Recommendations include:

- Pre-installation: Always lay out panels or rolls on flat surfaces prior to fixing for inspection and geometry confirmation.

- Post selection: Use corrosion-resistant steel or concrete posts, with intervals set according to wind and load studies (usually 2.5-3.0 meters apart).

- Anchoring: Employ tensioning tools and mechanical fasteners designed specifically for 100mm square mesh to avoid panel sagging or warping.

- Joining techniques: Welding or bolting at intersections enables performance continuity, especially on long runs and corner junctions.

- Safety standards: Mesh edges should be capped or turned inward to minimize injury risk around public or animal-accessible areas.

Periodic inspections, particularly in high-exposure sites, are imperative. Field data indicates that tightly managed maintenance protocols extend functional service life of installed mesh structures by up to 35% compared with unmonitored installations.

Conclusion: Why Wire Mesh 100mm x 100mm Remains the Industry Standard

The continued adoption of wire mesh 100mm x 100mm and its variants reflects a pattern of proven technical reliability, versatile customization, and consistent long-term returns. Whether specified as welded mesh 100mm x 100mm for high-security enclosures or 100mm square mesh for modern agricultural or architectural demands, it delivers on vital metrics: cost, efficiency, and durability.

With pressure for project completion timelines shortening and scrutiny on quality control intensifying, industry professionals favor solutions that align with international certifications, offer tailored engineering, and support sustainability mandates. Looking ahead, as manufacturing processes evolve towards even higher tolerances and smarter coatings, the role of mesh with the 100mm x 100mm specification is set to further expand.

For stakeholders seeking assured results across diverse environments, wire mesh 100mm x 100mm continues to define the benchmark in structural mesh performance.

(wire mesh 100mm x 100mm)

FAQS on wire mesh 100mm x 100mm

Q: What is wire mesh 100mm x 100mm?

A: Wire mesh 100mm x 100mm refers to mesh panels with 100mm by 100mm square openings. It is typically made from welded or woven wire. This size is commonly used for fencing and construction.Q: What materials are used for welded mesh 100mm x 100mm?

A: Welded mesh 100mm x 100mm is usually made from galvanized, stainless steel, or plain steel wire. The wires are welded at the intersections for strength. This makes it durable for outdoor or industrial projects.Q: What are the typical applications for 100mm square mesh?

A: 100mm square mesh is used for fencing, animal enclosures, and reinforcement in concrete. It provides good visibility and security. This mesh size is also utilized in landscaping and garden trellises.Q: Is wire mesh 100mm x 100mm suitable for animal fencing?

A: Yes, wire mesh 100mm x 100mm is suitable for large animal fencing like sheep, deer, and dogs. The mesh size prevents escape while allowing airflow. Always choose an appropriate wire thickness for animal safety.Q: Can wire mesh 100mm x 100mm be customized in length and height?

A: Yes, wire mesh 100mm x 100mm can be customized for specific projects. Manufacturers often offer various lengths, heights, and wire diameters. Customization ensures you get the best fit for your needs.-

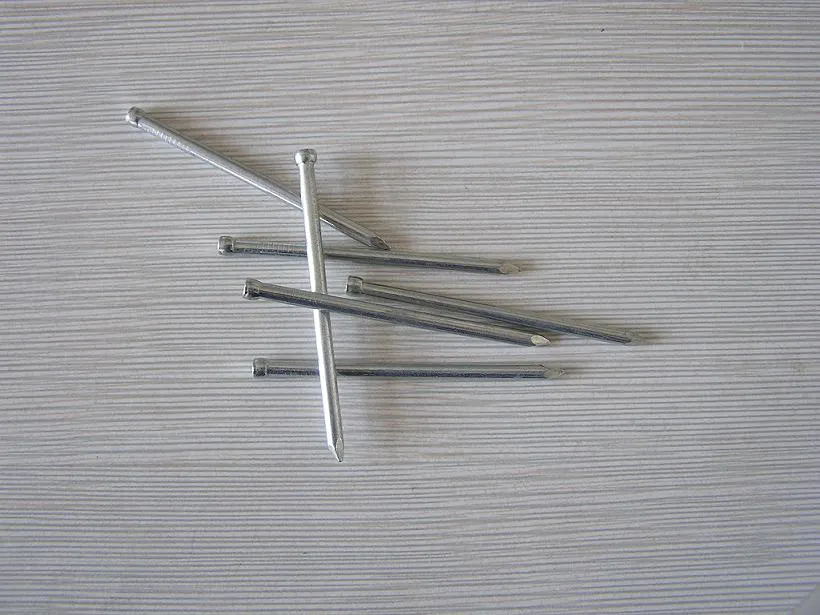

Types and Uses of Common Nails in Construction

NewsJul.31,2025

-

The Transformative Role of Square Wire Mesh in Contemporary Architecture

NewsJul.31,2025

-

The Essential Role of Razor Wire in Modern Perimeter Security

NewsJul.31,2025

-

Installation Guide for Hexagonal Wire Netting Fencing

NewsJul.31,2025

-

How to Properly Use Rebar Wire Ties for Stronger Concrete Structures

NewsJul.31,2025

-

Creative and Decorative Uses of Barbed Wire in Design

NewsJul.31,2025