Understanding CE Certification for High-Quality Bolts, Nuts, and Washers in the Manufacturing Industry

CE Certification for Bolts, Nuts, and Washers Understanding the Essentials

In the global marketplace, the safety and reliability of fasteners, including bolts, nuts, and washers, is paramount. With the increasing demand for high-quality fastening products in construction, automotive, and machinery industries, the importance of adhering to regulatory standards has never been higher. One such standard is the CE marking, a symbol that indicates compliance with European health, safety, and environmental protection standards.

What is CE Certification?

CE stands for Conformité Européenne, which translates to European Conformity. The CE marking signifies that a product meets the essential requirements stipulated by EU directives. For manufacturers exporting to the European Union (EU), obtaining CE certification for their products is not just a regulatory necessity; it serves as a mark of quality assurance, instilling trust in consumers and businesses alike.

Importance of CE Certification for Fasteners

1. Safety Assurance Fasteners play a critical role in the structural integrity of various products. Bolts, nuts, and washers must withstand significant loads and forces. CE certification ensures that these components have been tested for strength, durability, and reliability under certain conditions.

2. Market Access European markets can be particularly stringent regarding product standards. Without CE marking, manufacturers may find it difficult, if not impossible, to market their fasteners in the EU. CE certification helps facilitate smoother access to these lucrative markets.

3. Competitive Advantage In a crowded marketplace, products that are CE certified often stand out. This certification can be a compelling selling point, demonstrating a commitment to quality and compliance that can attract more customers.

4. Minimizes Liability Risks By ensuring that fasteners meet safety standards, manufacturers can help minimize the risk of accidents and defects associated with non-compliant products. This factor is essential not only for consumer safety but also for protecting the manufacturer from potential lawsuits and recalls.

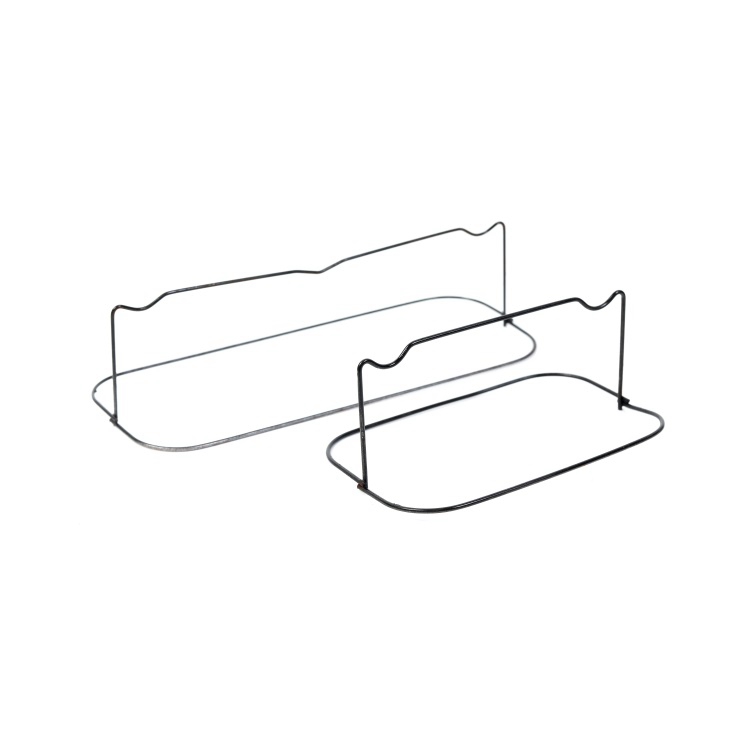

ce certification bolts nuts and washers

The CE Certification Process for Bolts, Nuts, and Washers

The process for CE certification generally includes the following steps

1. Determine Applicable Directives Manufacturers must identify which EU directives apply to their fasteners. For example, the Construction Products Regulation (CPR) is critical when dealing with construction-related products.

2. Testing and Evaluation Fasteners must undergo testing to demonstrate compliance with relevant standards. This includes checks for material properties, performance under load, and corrosion resistance, among other factors.

3. Quality Control System Establishing a quality control system that complies with EU regulations is vital. This process often necessitates involvement with a Notified Body, which can provide the necessary assessments and certifications.

4. Documentation Keeping a Declaration of Conformity (DoC) and maintaining technical documentation is crucial for CE marking. This documentation serves as proof that the product adheres to the appropriate standards.

5. Affix the CE Marking Once compliance is confirmed, manufacturers can affix the CE mark to their products. This mark must be visible, legible, and indelible, ensuring that it remains on the product throughout its lifecycle.

Conclusion

In conclusion, CE certification for bolts, nuts, and washers is an essential component of manufacturing quality fasteners for the European market. It not only assures safety and reliability but also enhances market competitiveness and reduces liability risks. With the complexities of international trade and stringent safety standards, manufacturers who prioritize CE compliance will not only safeguard their products but also position themselves favorably in a dynamic global marketplace. As demand for high-quality fasteners continues to rise, understanding and navigating the CE certification process is more critical than ever.

-

The Durability and Versatility of Steel Wire

NewsJun.26,2025

-

The Best Iron Nails for Your Construction Projects

NewsJun.26,2025

-

Strengthen Your Projects with Durable Metal Stakes

NewsJun.26,2025

-

Get the Job Done Right with Duplex Nails

NewsJun.26,2025

-

Explore the Versatility and Strength of Metal Mesh

NewsJun.26,2025

-

Enhance Your Security with Razor Wire

NewsJun.26,2025