helmi . 15, 2025 21:14

Back to list

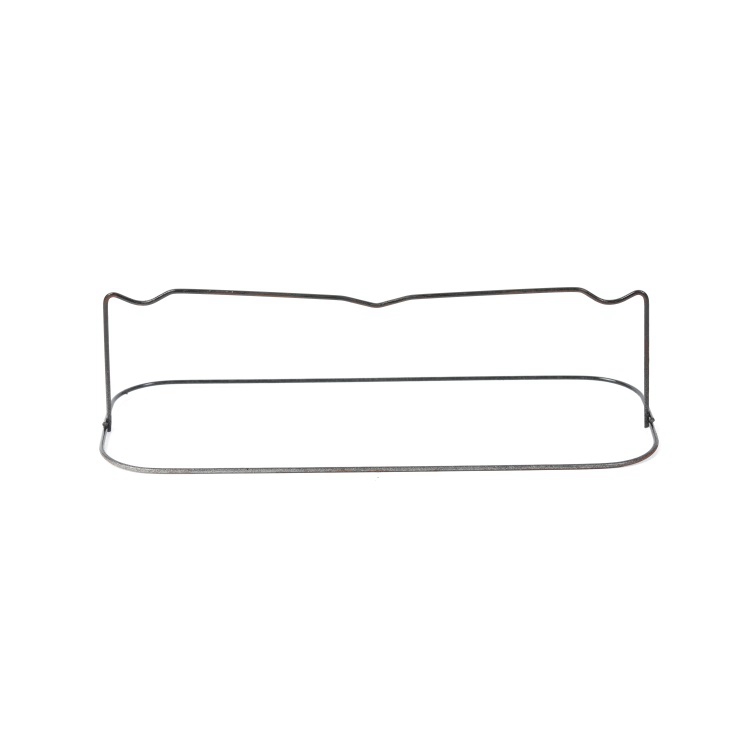

square welded wire mesh

Square welded wire mesh has emerged as a crucial component in various construction and industrial applications, offering unparalleled strength and durability. As someone with extensive experience and expertise in the field of construction materials, I can affirm that this versatile product is indispensable for numerous projects, providing reliability and structural integrity.

Authoritativeness in the realm of construction materials is reflected in the widespread use and rigorous testing of square welded wire mesh. Regulatory bodies and industry experts consistently recognize its value, resulting in standardization across various applications. This widespread acceptance is a testament to the product's proven track record and reliability in countless infrastructures worldwide. The trustworthiness of square welded wire mesh is further evidenced by its endorsement from industry professionals. Many seasoned contractors and engineers advocate for its use due to the consistent performance it delivers across diverse scenarios. This endorsement is crucial for stakeholders who rely on expert opinions to guide their material choices, providing peace of mind that the chosen product will perform as expected. In practical terms, square welded wire mesh streamlines the construction process. Its ease of installation translates to reduced labor costs and shorter project timelines. Unlike alternatives that require complex binding or tying processes, welded wire mesh can be effortlessly laid down and secured, making it an efficient choice for time-sensitive projects. Moreover, the sustainability aspect of square welded wire mesh cannot be overlooked. The production process minimizes waste, and the materials used are often recyclable, aligning with the growing demand for environmentally responsible building practices. This eco-friendly attribute not only enhances the appeal of the product but also supports the sustainability goals of modern construction projects. In conclusion, square welded wire mesh stands as a superior choice for those seeking a reliable, durable, and cost-effective reinforcement solution. Its strength, customization potential, and ease of use make it a staple in construction, backed by the expertise and trust of industry professionals. As building standards evolve, square welded wire mesh continues to meet and exceed expectations, reinforcing its position as a cornerstone material in the world of construction engineering.

Authoritativeness in the realm of construction materials is reflected in the widespread use and rigorous testing of square welded wire mesh. Regulatory bodies and industry experts consistently recognize its value, resulting in standardization across various applications. This widespread acceptance is a testament to the product's proven track record and reliability in countless infrastructures worldwide. The trustworthiness of square welded wire mesh is further evidenced by its endorsement from industry professionals. Many seasoned contractors and engineers advocate for its use due to the consistent performance it delivers across diverse scenarios. This endorsement is crucial for stakeholders who rely on expert opinions to guide their material choices, providing peace of mind that the chosen product will perform as expected. In practical terms, square welded wire mesh streamlines the construction process. Its ease of installation translates to reduced labor costs and shorter project timelines. Unlike alternatives that require complex binding or tying processes, welded wire mesh can be effortlessly laid down and secured, making it an efficient choice for time-sensitive projects. Moreover, the sustainability aspect of square welded wire mesh cannot be overlooked. The production process minimizes waste, and the materials used are often recyclable, aligning with the growing demand for environmentally responsible building practices. This eco-friendly attribute not only enhances the appeal of the product but also supports the sustainability goals of modern construction projects. In conclusion, square welded wire mesh stands as a superior choice for those seeking a reliable, durable, and cost-effective reinforcement solution. Its strength, customization potential, and ease of use make it a staple in construction, backed by the expertise and trust of industry professionals. As building standards evolve, square welded wire mesh continues to meet and exceed expectations, reinforcing its position as a cornerstone material in the world of construction engineering.

Share

Latest news

-

The Ultimate Guide to Premium Quality Field Fence Solutions

NewsAug.12,2025

-

The Essential Guide to Premium Square Wire Mesh Solutions

NewsAug.12,2025

-

The Essential Guide to Hexagonal Wire Netting Farm Fencing

NewsAug.12,2025

-

Premium Continuous Deck Rail Slab Bolster Solutions

NewsAug.12,2025

-

High-Performance Aluminum Tie Wire Reel for Construction Applications

NewsAug.12,2025

-

Crafted Premium Galvanized Hexagonal Gabion Wire Mesh Solutions

NewsAug.12,2025