Feb . 12, 2025 17:15

Back to list

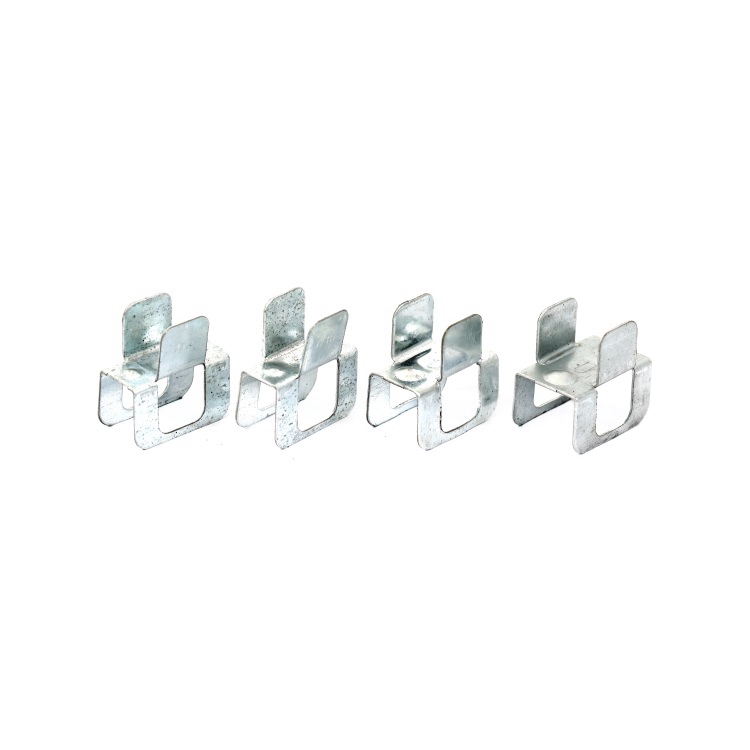

STEEL GROUND NAIL GARDEN STAKES

Galvanized PVC welded wire mesh is gaining significant traction in various applications due to its remarkable durability, adaptability, and cost-effectiveness. This versatile product is crafted by welding thin steel wires together, followed by a galvanization process that coats the mesh with zinc or a zinc alloy to prevent corrosion. A subsequent layer of PVC adds an extra shield of protection, making it an ideal solution for both indoor and outdoor uses.

Trustworthiness is crucial when selecting materials for any project, and galvanized PVC welded wire mesh provides it in spades. Numerous case studies document its effectiveness in diverse settings, providing evidence of its reliability. For example, security experts often choose this mesh for perimeter fencing due to its resistance to cutting and tampering, providing peace of mind through enhanced safety. Homeowners and business proprietors alike appreciate this, citing waylays and theft deterred by its presence. One cannot overlook the cost-effectiveness of using galvanized PVC welded wire mesh. Its dual-layer protection means that, over time, maintenance costs are significantly reduced compared to other materials prone to corrosion or requiring frequent repairs. Furthermore, its easy-to-cut and mold properties make it ideal for DIY enthusiasts and professionals alike, ensuring quick and efficient installation. This adaptability results in reduced manpower and time expenses, making it a preferred choice for budget-conscious projects without compromising on quality or durability. End-users have shared stories of success using this mesh in innovative ways such as in artistic sculptures, garden trellises, and decorative enclosures, highlighting its versatility beyond traditional applications. These first-hand experiences amplify the product's credibility, demonstrating real-world scenarios of its multifaceted use and dependability. In summary, galvanized PVC welded wire mesh is a product that embodies strength, durability, and flexibility. Its strategic design and protective layering serve to extend its lifecycle, making it a reliable choice for a multitude of applications. Asmore industries and individuals turn to this robust solution, they find it consistently meets and exceeds expectations — testament to its standing as a premier material in its class. Trust in the mesh has been built not only through rigorous quality assurance but also through countless successful applications globally, setting a benchmark for others to follow.

Trustworthiness is crucial when selecting materials for any project, and galvanized PVC welded wire mesh provides it in spades. Numerous case studies document its effectiveness in diverse settings, providing evidence of its reliability. For example, security experts often choose this mesh for perimeter fencing due to its resistance to cutting and tampering, providing peace of mind through enhanced safety. Homeowners and business proprietors alike appreciate this, citing waylays and theft deterred by its presence. One cannot overlook the cost-effectiveness of using galvanized PVC welded wire mesh. Its dual-layer protection means that, over time, maintenance costs are significantly reduced compared to other materials prone to corrosion or requiring frequent repairs. Furthermore, its easy-to-cut and mold properties make it ideal for DIY enthusiasts and professionals alike, ensuring quick and efficient installation. This adaptability results in reduced manpower and time expenses, making it a preferred choice for budget-conscious projects without compromising on quality or durability. End-users have shared stories of success using this mesh in innovative ways such as in artistic sculptures, garden trellises, and decorative enclosures, highlighting its versatility beyond traditional applications. These first-hand experiences amplify the product's credibility, demonstrating real-world scenarios of its multifaceted use and dependability. In summary, galvanized PVC welded wire mesh is a product that embodies strength, durability, and flexibility. Its strategic design and protective layering serve to extend its lifecycle, making it a reliable choice for a multitude of applications. Asmore industries and individuals turn to this robust solution, they find it consistently meets and exceeds expectations — testament to its standing as a premier material in its class. Trust in the mesh has been built not only through rigorous quality assurance but also through countless successful applications globally, setting a benchmark for others to follow.

Share

Latest news

-

The Ultimate Guide to Premium Quality Field Fence Solutions

NewsAug.12,2025

-

The Essential Guide to Premium Square Wire Mesh Solutions

NewsAug.12,2025

-

The Essential Guide to Hexagonal Wire Netting Farm Fencing

NewsAug.12,2025

-

Premium Continuous Deck Rail Slab Bolster Solutions

NewsAug.12,2025

-

High-Performance Aluminum Tie Wire Reel for Construction Applications

NewsAug.12,2025

-

Crafted Premium Galvanized Hexagonal Gabion Wire Mesh Solutions

NewsAug.12,2025