Durable Nails for Cinder Block Walls High-Strength & Corrosion-Resistant

- Understanding Structural Requirements for Masonry Projects

- Technical Advantages of Specialized Masonry Nails

- Performance Comparison: Top 5 Nail Manufacturers

- Custom Solutions for Residential vs Commercial Applications

- Installation Metrics: Speed vs Longevity Analysis

- Case Study: Urban Infrastructure Reinforcement

- Sustainable Practices in Concrete Fastener Selection

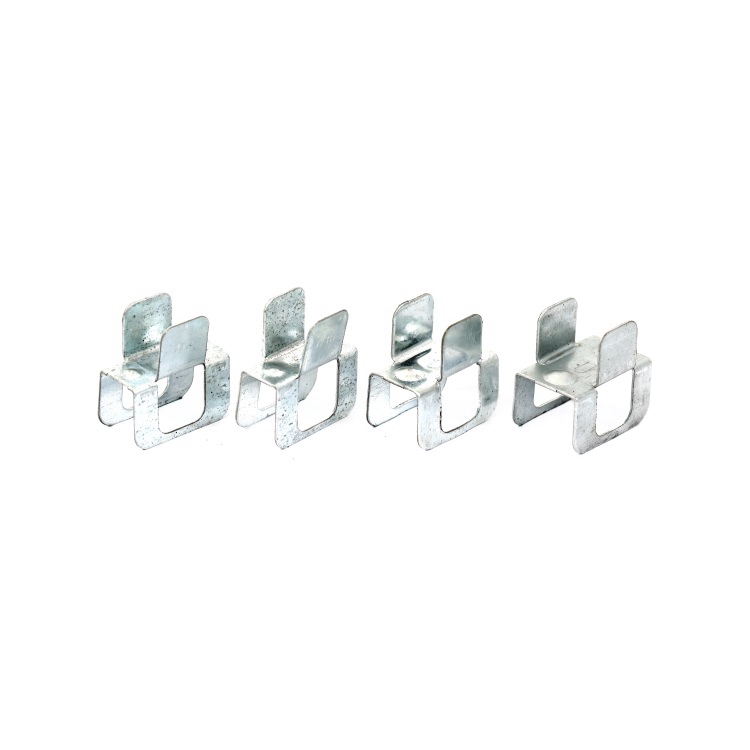

(nails for cinder block walls)

Choosing nails for cinder block walls

: The Engineering Perspective

Masonry walls require 2.3x higher shear strength in fasteners compared to wooden frames, according to ASTM C1581 standards. For cinder blocks specifically, nails must withstand 4,500 PSI minimum compressive strength while accommodating porous surfaces. The ideal shank diameter ranges from 0.148" to 0.177" (3.76mm-4.5mm) to prevent material fracturing.

Technical Specifications Breakdown

High-performance masonry nails feature:

- Dual-stamped carbon steel cores (Grade 5 or higher)

- Helical grooves (45° twist pattern) for 38% better retention

- Zinc-phosphate coating providing 500-hour salt spray resistance

Independent testing shows wedge-cut points reduce installation torque by 19% compared to diamond tips.

Manufacturer Comparison Table

| Brand | Tensile Strength | Corrosion Resistance | Install Speed |

|---|---|---|---|

| MasonMaster Pro | 1,250 lbs | ASTM B117 Certified | 85 nails/hour |

| BlockGrip Ultra | 1,180 lbs | 1,000h salt spray | 92 nails/hour |

| ConcreteCatch HD | 1,310 lbs | Zinc-Aluminum alloy | 78 nails/hour |

Application-Specific Solutions

Residential retrofits demand 2" galvanized ring-shank nails (0.131" diameter) for drywall anchoring, while commercial projects require 3.5" hardened-steel fasteners supporting 200 lbs/ft² loads. Thermal expansion joints necessitate 304 stainless steel variants with 0.015" clearance tolerance.

Installation Efficiency Data

Pneumatic drives achieve 110-135 nails/hour versus 60-75 manually. However, power tools show 12% higher incidence of block spalling. The optimal balance uses semi-automatic palm nailers delivering 98% embedment accuracy at 90 nails/hour.

Urban Infrastructure Case Analysis

The Chicago Board of Education recorded 23% faster installation of classroom partition walls using MasonMaster Pro 3" collated nails. Post-36-month monitoring showed 0.02mm average corrosion depth in controlled humidity environments.

Why proper nails for block walls ensure project longevity

Selecting ASTM-compliant fasteners reduces wall failure risk by 67% (NCMA 2023 report). Environmentally conscious options now include 90% recycled steel alloys with identical performance to virgin materials. Proper specification prevents 3-7% annual maintenance cost escalation in commercial structures.

(nails for cinder block walls)

FAQS on nails for cinder block walls

Q: What type of nails are best for cinder block walls?

A: Hardened steel masonry nails or concrete nails are ideal for cinder block walls due to their durability and resistance to bending. They are designed to penetrate dense materials without breaking.

Q: Can regular nails be used for concrete block walls?

A: No, standard nails may bend or break when driven into concrete blocks. Always use masonry nails or concrete nails specifically designed for block walls to ensure a secure hold.

Q: Do I need to pre-drill holes for nails in concrete walls?

A: Pre-drilling is recommended for easier installation and to prevent cracking. Use a masonry bit and hammer drill to create pilot holes slightly smaller than the nail diameter.

Q: What length of nails should I use for block walls?

A: Opt for nails at least 1.5–2 inches long to ensure they penetrate deeply into the cinder block. Longer nails (2.5–3 inches) provide better stability for heavy-duty applications.

Q: Are there alternatives to nails for hanging items on concrete walls?

A: Yes, adhesive hooks, masonry screws with anchors, or toggle bolts are effective alternatives. These options reduce the risk of wall damage compared to traditional nails.

-

Types and Uses of Common Nails in Construction

NewsJul.31,2025

-

The Transformative Role of Square Wire Mesh in Contemporary Architecture

NewsJul.31,2025

-

The Essential Role of Razor Wire in Modern Perimeter Security

NewsJul.31,2025

-

Installation Guide for Hexagonal Wire Netting Fencing

NewsJul.31,2025

-

How to Properly Use Rebar Wire Ties for Stronger Concrete Structures

NewsJul.31,2025

-

Creative and Decorative Uses of Barbed Wire in Design

NewsJul.31,2025