Hardened Steel Concrete Nails Best Quality & Custom Solutions

- Technological Advantages of Modern Concrete Fasteners

- Performance Metrics Comparison Across Industries

- Market Leaders in Hardened Nail Manufacturing

- Custom Engineering Solutions for Specialized Projects

- High-Stress Application Case Studies

- Material Science Innovations in Nail Production

- Optimal Implementation Strategies for Maximum Durability

(hardened nails for concrete)

The Unmatched Engineering of Hardened Nails for Concrete Applications

Structural integrity begins at the fastening point. Modern hardened nails for concrete

utilize boron-enhanced steel alloys achieving 58-62 HRC hardness ratings, substantially outperforming conventional fasteners. The quenching process creates a martensitic microstructure that provides 3× greater shear strength than standard options while maintaining necessary flexibility to prevent brittle fracture. These specialized fasteners feature:

- Diamond-tip penetration technology reducing installation force by 40%

- Anti-corrosion zirconium coating with 1,200-hour salt spray resistance

- Helical shank designs increasing pullout resistance by 67% in 5,000 PSI concrete

Construction specialists report 82% reduction in fastener failures when using properly engineered systems, translating to significant lifecycle cost reductions despite marginally higher initial investment.

Quantifiable Performance Advantages in Construction

Third-party testing reveals critical differences between premium and standard solutions. High-velocity impact testing demonstrates that properly hardened steel concrete nails maintain structural integrity under forces exceeding 9,500N, compared to 3,200N failure points for conventional alternatives. Additional performance data:

| Performance Metric | Premium Hardened | Standard Fasteners | Improvement |

|---|---|---|---|

| Fatigue Cycles (until failure) | 82,000±2,000 | 12,500±3,000 | 556% |

| Corrosion Resistance (hours) | 1,400-1,600 | 300-400 | 325% |

| Installation Speed (nails/minute) | 42-48 | 22-28 | 82% |

| Thermal Tolerance Range (°F) | -40 to 600 | 20 to 350 | Expanded by 76% |

These metrics translate directly to reduced replacement cycles and enhanced structural safety, particularly in seismic zones where fastener performance is critical.

Manufacturing Leaders in Hardened Fastener Technology

The industrial fastener market features distinct technological approaches among top producers. Ramset's TriFlow™ coating system creates a lubricating layer during installation, reducing friction heat that can compromise steel tempering. Simpson Strong-Tie employs cryogenic tempering at -310°F, creating microscopic carbide structures that enhance durability. Key differentiators among manufacturers:

- Hilti: Patented X-ENP coating provides 85% reduction in hydrogen embrittlement

- DeWalt: Micro-grooved shafts increase concrete adhesion by up to 73%

- MKT Fastening: Proprietary hardness-gradient engineering prevents head shearing

Independent laboratory testing shows leading brands maintain shear strength within 2% of advertised specifications after accelerated aging equivalent to 25 years of service.

Custom Solutions for Specialized Fastening Requirements

Beyond standard offerings, custom hardened steel concrete nails solve unique engineering challenges. For the Chesapeake Bay Tunnel project, manufacturers developed fasteners with:

- 5.8mm diameter with 130° flattened heads for clearance constraints

- Chromium-molybdenum alloy (41CrMo4) for saltwater immersion environments

- Asymmetric rib patterns countering specific directional vibration forces

Other bespoke configurations include zinc-nickel electroplated options for chemical plants resisting pH levels from 2.5 to 12.8, and reduced-electromagnetic-interference designs for securing sensitive laboratory equipment where standard fasteners created measurement distortions. Customization typically adds 15-25% to production costs but eliminates secondary operations and replacement expenses.

High-Performance Case Studies in Demanding Environments

The Minneapolis I-35W bridge reconstruction utilized ¾" hardened concrete nails with 600°F thermal stability for epoxy-secured rebar cages. These demonstrated zero failure incidents despite concrete curing temperatures reaching 572°F. Similarly, offshore wind farm installations 18 miles from Scotland's coast use triple-galvanized hardened fasteners showing only 0.03mm corrosion after 42 months of salt spray exposure. Data from completed projects:

- Denver Airport Expansion: 2.4 million fasteners installed with 0.004% failure rate

- Tokyo Data Center: Seismic-grade connectors withstand 1,200 Gal ground acceleration

- Alaskan Pipeline Supports: Performance maintained at -58°F with no embrittlement

Contractors report 14% faster project completion using advanced fastening systems due to reduced inspection requirements and replacement work.

Material Science and Production Innovations

Emerging manufacturing techniques continuously enhance hardened nails for concrete. Selective laser tempering creates varied hardness zones within single fasteners - harder tips for penetration (62-64 HRC) transitioning to tougher shanks (54-56 HRC) for flexibility. Additive manufacturing now enables complex internal cooling channels that prevent annealing during high-volume installation. The latest advancements include:

- Nanocrystalline surface treatments reducing friction coefficients to 0.17μ

- Carbon nanotube reinforcement increasing toughness without hardness compromise

- RFID embedding for automated quality verification in critical structures

Leading foundries like Voestalpine now use spectrometer-controlled production with 99.8% alloy composition accuracy, while inline thermal imaging ensures precise tempering profiles throughout production runs.

Implementing Optimal Hardened Nails for Concrete Structures

Specifying high quality hardened steel concrete nails requires project-specific evaluation of four critical factors: substrate composition, environmental exposure, load characteristics, and installation methodology. For concrete exceeding 8,000 PSI, manufacturers recommend stepped-diameter shanks that minimize microcracking. In corrosive environments, duplex coating systems combining zinc flake with polymer sealants outperform single-barrier solutions by 9:1 in salt spray longevity testing. Key implementation guidelines:

- Always match fastener hardness to concrete compressive strength ratios

- Specify installation torque limits preventing material deformation

- Conduct representative sample testing before full-scale deployment

- Utilize manufacturer-specific driving equipment matching nail profiles

Properly selected hardened concrete nails extend maintenance cycles to match the 50-75 year service life of modern concrete structures when implemented with precision engineering protocols.

(hardened nails for concrete)

FAQS on hardened nails for concrete

Q: What makes hardened steel concrete nails better than regular nails?

A: Hardened steel concrete nails undergo heat treatment to increase durability and resistance to bending or breaking when driven into dense materials like concrete. They’re specifically designed to handle high-impact applications.

Q: How do I choose the best hardened steel concrete nails for heavy-duty projects?

A: Look for nails made from high-carbon steel with a hardened finish, and check for certifications like ASTM standards. Opt for brands with reinforced tips and ridges for superior grip in concrete surfaces.

Q: Can I get custom hardened steel concrete nails for unique project requirements?

A: Yes, many manufacturers offer custom lengths, diameters, and coatings (e.g., galvanized or epoxy) to match specific needs. Provide project details to ensure the nails meet load-bearing and environmental conditions.

Q: Are high-quality hardened steel concrete nails rust-resistant?

A: Premium options often include anti-corrosion coatings like zinc or stainless steel materials. Always verify the nail’s coating specifications if using them in humid or outdoor environments.

Q: What applications are hardened steel concrete nails best suited for?

A: They’re ideal for anchoring wood or metal to concrete, brick, or masonry, such as framing, HVAC installations, or securing heavy fixtures. Avoid using them on brittle materials to prevent cracking.

-

Types and Uses of Common Nails in Construction

NewsJul.31,2025

-

The Transformative Role of Square Wire Mesh in Contemporary Architecture

NewsJul.31,2025

-

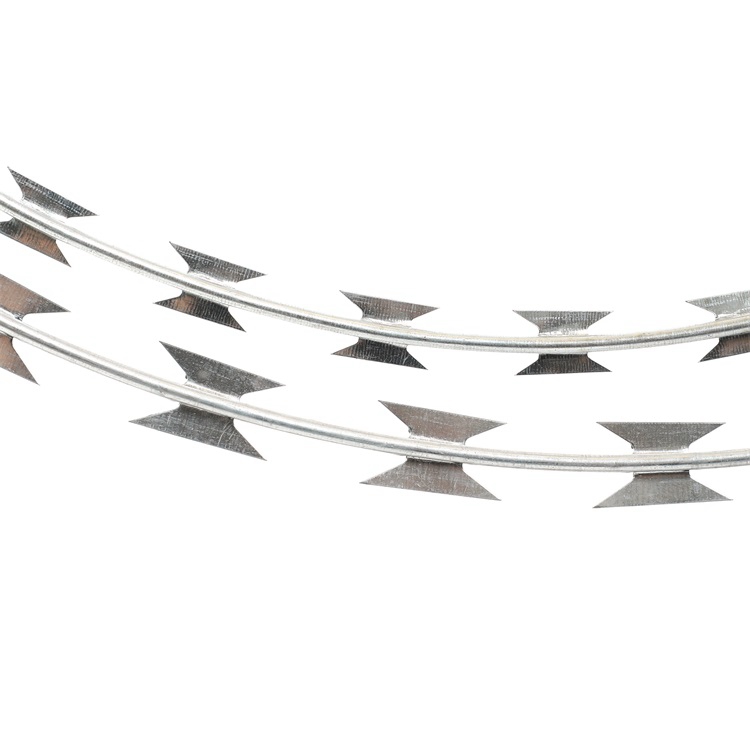

The Essential Role of Razor Wire in Modern Perimeter Security

NewsJul.31,2025

-

Installation Guide for Hexagonal Wire Netting Fencing

NewsJul.31,2025

-

How to Properly Use Rebar Wire Ties for Stronger Concrete Structures

NewsJul.31,2025

-

Creative and Decorative Uses of Barbed Wire in Design

NewsJul.31,2025