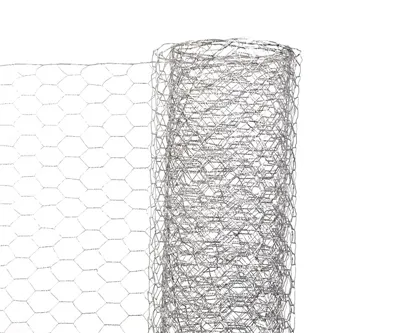

wire cloth

Understanding Wire Cloth A Versatile Material in Industry and Craft

Wire cloth, also known as wire mesh or wire fabric, is one of the most versatile materials available, utilized in various industries and crafts. Its unique properties and diverse applications make it a staple in construction, manufacturing, agriculture, and even art. This article will explore the significance of wire cloth, its manufacturing processes, characteristics, applications, and the future of this indispensable material.

What is Wire Cloth?

Wire cloth is typically made from various metals, including stainless steel, aluminum, copper, and bronze. The most common type is made from stainless steel due to its strength, corrosion resistance, and longevity. Wire cloth consists of a series of interwoven wires that create an open grid structure, allowing for airflow and liquid passage while providing solid support. The mesh can come in different weave patterns, openings, and wire diameters, granting it a range of functional and aesthetic characteristics.

Manufacturing Process

The manufacturing of wire cloth involves several key steps. Initially, the wires are drawn to the desired diameter before being cleaned and coated to prevent corrosion. Next, the wires are woven into the desired mesh pattern. The essential weaving types include plain weave, twill weave, and Dutch weave, each offering unique characteristics suited for different applications. Following the weaving process, the wire cloth may undergo additional treatments, such as galvanization or welding, to enhance its strength and durability.

Characteristics of Wire Cloth

Wire cloth exhibits several significant characteristics that enhance its usability. Its strength and durability make it ideal for demanding applications, while its flexibility allows for various designs and shapes. Additional features include resistance to high temperatures, excellent filtering capabilities, and the ability to withstand harsh environmental conditions.

One of the most crucial aspects of wire cloth is its versatility in wire openings. The size of the openings can be customized, providing precise filtration and separation capabilities. This adaptability makes wire cloth suitable for various applications, from industrial filtration systems to decorative elements in architecture.

Applications of Wire Cloth

Wire cloth is employed across multiple industries, showcasing its extensive versatility

wire cloth

1. Filtration In industries such as pharmaceuticals, food processing, and oil and gas, wire cloth serves as a primary filtration material. Its precision in separating solids from liquids makes it crucial for maintaining product purity and quality.

2. Construction In construction, wire cloth is used in concrete reinforcement, providing structural support and preventing cracking. It can also be part of building facades, aiding in climate control and aesthetic appeal.

3. Manufacturing Wire cloth plays a critical role in various manufacturing processes, particularly in sorting and conveying materials. Its ability to support heavy loads while allowing airflow makes it ideal for industrial applications.

4. Agriculture In agriculture, wire cloth is commonly used in screens, animal enclosures, and fencing. Its durability ensures long-lasting solutions that protect crops and livestock.

5. Art and Design The aesthetic appeal of wire cloth has captured the attention of artists and designers. It is often used in sculptures, installations, and architectural features, demonstrating the balance between function and creativity.

The Future of Wire Cloth

As technology advances, the future of wire cloth appears promising. Innovations in material science may lead to the development of new alloys and weaving techniques, enhancing its properties even further. Additionally, the rising focus on sustainability in manufacturing processes may lead to more eco-friendly options for wire cloth production.

In recent years, there’s also been a growing trend towards incorporating wire cloth into smart technologies. With the integration of sensors and IoT capabilities, wire cloth could serve roles in advanced filtration systems, environmental monitoring, and even healthcare applications.

Conclusion

Wire cloth is a material that exemplifies the intersection of functionality, versatility, and durability. Its various applications across multiple industries, along with its potential for sustainable and innovative advancements, ensure its continued relevance in the modern world. Whether in a manufacturing plant, a construction site, or an art studio, wire cloth remains an essential component contributing to efficiency, safety, and creativity. Understanding its properties and applications helps us appreciate the role it plays in our daily lives and the industries that shape our future.

-

Transform Your Outdoor Spaces with High-Quality Gabions

NewsJul.23,2025

-

The Power and Versatility of Wire Mesh for Your Projects

NewsJul.23,2025

-

The Complete Guide to Annealed Wire

NewsJul.23,2025

-

Pallet Nails--The Essential Fastener for Pallet Construction

NewsJul.23,2025

-

Anchor Bolt Analysis: A Key Component to Ensure Building Stability

NewsJul.23,2025

-

Enhance Your Property Security with Quality Barbed Wire

NewsJul.23,2025